Water-based semiconductor wafer cutting fluid and preparation method thereof

A cutting fluid and semiconductor technology, applied in the petroleum industry, lubricating composition, etc., can solve problems such as surface corrosion, silicon powder residue, wafer mechanical damage, etc.

Pending Publication Date: 2021-09-24

广州亦盛环保科技有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The purpose of the present invention is to provide a water-based semiconductor wafer cutting fluid and a preparation method thereof, which can solve the problems of wafe

Method used

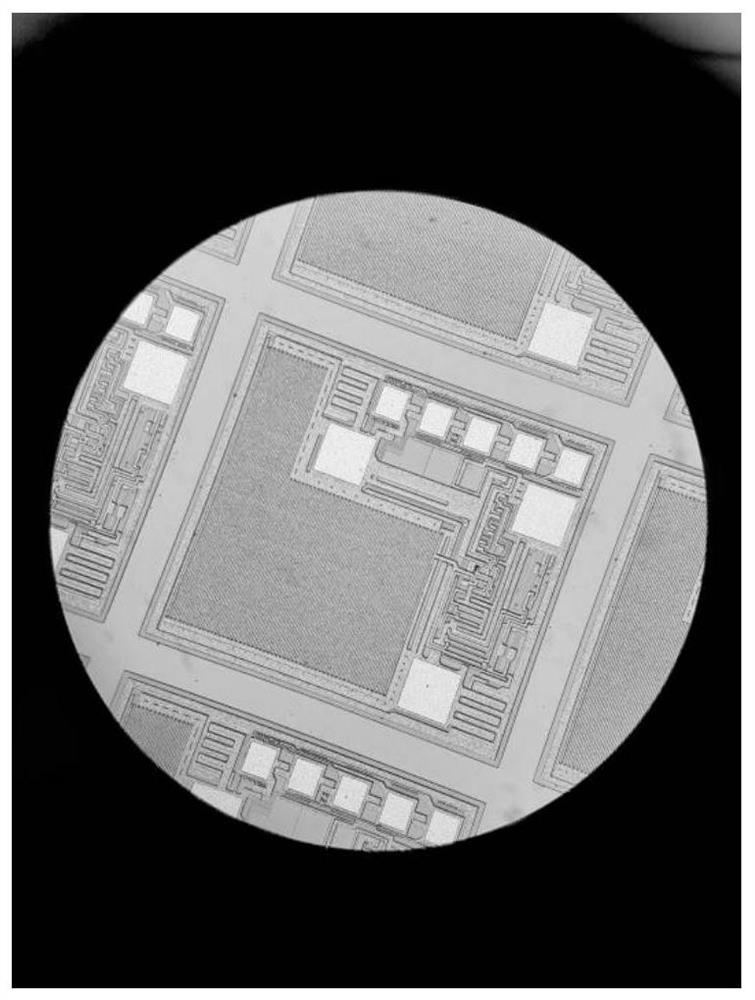

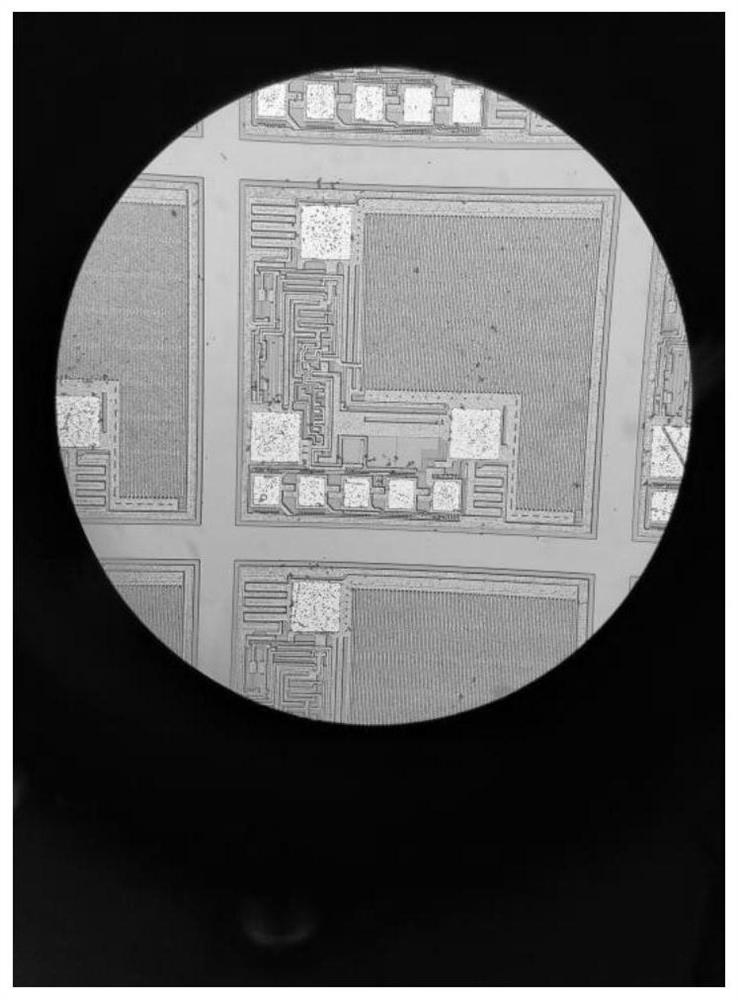

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

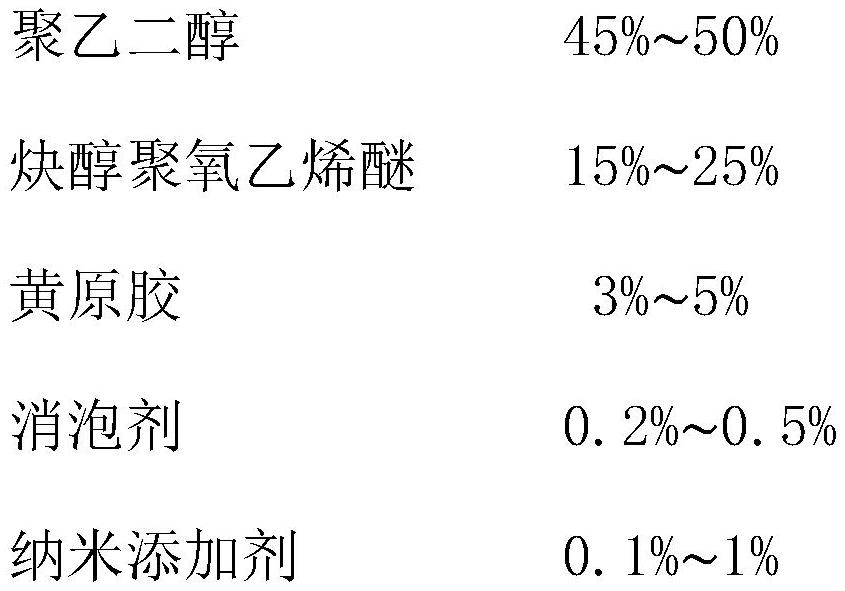

The invention provides a water-based semiconductor wafer cutting fluid and a preparation method thereof. The water-based semiconductor wafer cutting fluid is mainly composed of polyethylene glycol, alkynol polyoxyethylene ether, xanthan gum, a defoaming agent and deionized water, and the wafer cutting fluid also contains a nano additive. The raw materials are sequentially put into a stirrer according to a certain proportion to be uniformly mixed into a single liquid phase, and the semiconductor wafer cutting fluid can be prepared. The semiconductor wafer cutting fluid has the advantages of excellent lubricity, excellent cooling and cleaning performance, small mechanical stress damage to wafers and no corrosion to the surfaces of the wafers. The cutting fluid product meets the environmental protection requirements of ROSH, REACH, HF, VOC and the like, and is environmentally friendly.

Description

technical field [0001] The invention relates to the technical field of semiconductor wafers, in particular to an aqueous semiconductor wafer cutting fluid. Background technique [0002] In the semiconductor chip manufacturing process, semiconductor wafer cutting is an essential process step. Usually hundreds of thousands of tiny chips are arranged in an orderly manner on the semiconductor wafer. independent chip. [0003] During the cutting process of semiconductor wafers, due to the action of strong mechanical force, the edges of semiconductor wafers are prone to damage to varying degrees, which is an important factor for the breakage of semiconductor wafers and chips. At the same time, the residue particles generated during the dicing process will adhere to the surface and sidewall of the wafer, and it is difficult to completely remove them in the subsequent cleaning process, which will also have a certain impact on the quality of the product. In order to reduce the sur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M173/02C10N30/04C10N30/06C10N30/12

CPCC10M173/02C10M2201/105C10M2209/104C10M2209/108C10M2209/12C10N2030/04C10N2030/06C10N2030/12

Inventor 胡丁包亚群

Owner 广州亦盛环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com