Three-dimensional bionic self-healing hydrogel fiber scaffold composition and preparation method and application thereof

A technology of hydrogel fibers and fiber scaffolds, which is applied in the field of biomedicine, can solve the problems that the scaffolds do not have the strength of muscle kinematics and the synthesis process is complicated, and achieve good clinical application prospects, good biocompatibility, and increase the speed of tissue regeneration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

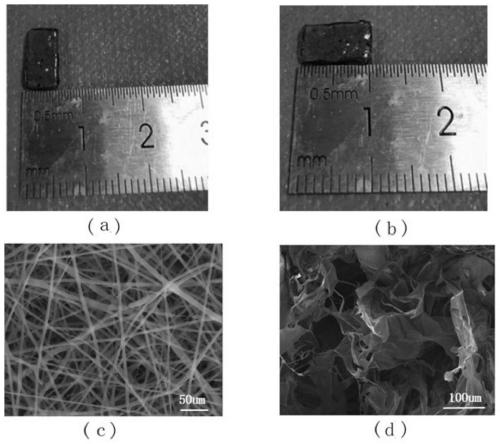

Embodiment 1

[0053] A three-dimensional bionic self-healing hydrogel fiber scaffold, the preparation method of which is as follows:

[0054] Take the biocompatible material with a weight ratio of 99%, and the nanomaterial with a weight ratio of 1%, which is a composition for a fiber scaffold; the biocompatible material is preferably polycaprolactone, and the nanomaterial is preferably single-layer graphite alkene.

[0055] Polycaprolactone is dissolved in a solvent 10 times the weight of the composition, and then graphene is added and mixed thoroughly to obtain a composition solution capable of forming a fiber film. The solvent is preferably dichloromethane.

[0056] After the above-mentioned graphene composition solution is debubbled by an ultrasonic machine, inject it into the injector, output it at a flow rate of 0.1ml / min, and spray it onto a receiving plate with a length of 30cm and a width of 20cm. The negative voltage is -4KV, and the positive voltage is It is 12KV, and the receivi...

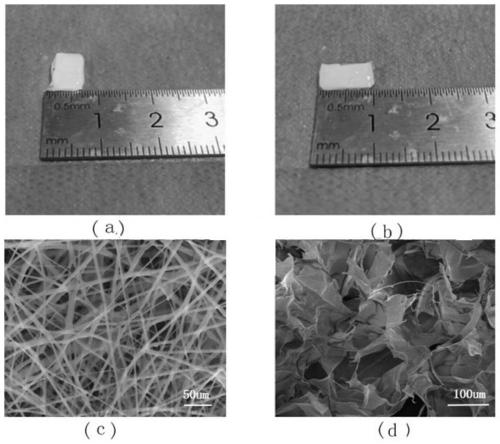

Embodiment 2

[0063] A three-dimensional bionic hydrogel fiber scaffold, the preparation method of which is as follows:

[0064] Take the biocompatible material with a weight ratio of 99%, and the small molecular compound with a weight ratio of 1%, which is a fiber scaffold composition; the biocompatible material is preferably polycaprolactone, and the nanomaterial is preferably melatonin .

[0065] Polycaprolactone is dissolved in a solvent 10 times the weight of the composition, and then melatonin is added and mixed well to obtain a composition solution capable of forming a fibrous film. The solvent is preferably dichloromethane.

[0066] After removing bubbles from the above-mentioned melatonin composition solution with an ultrasonic machine, inject it into the injection device, output it at a flow rate of 0.1ml / min, and spray it onto a receiving plate with a length of 30cm and a width of 20cm, negative voltage -4KV, positive voltage It is 12KV, and the receiving distance is 25cm; the e...

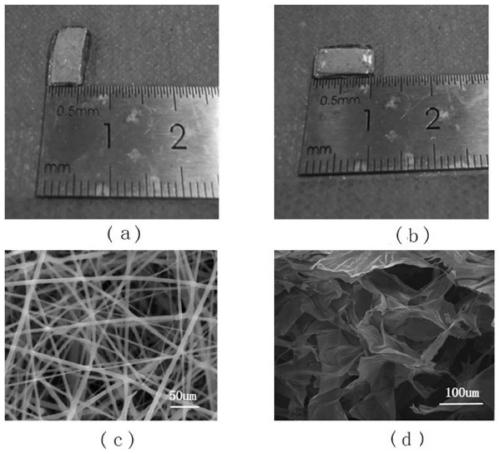

Embodiment 3

[0073] A three-dimensional bionic hydrogel fiber scaffold, the preparation method of which is as follows:

[0074] The biocompatible material with a weight ratio of 98%, the nanometer material with a weight ratio of 1%, and the small molecular compound with a weight ratio of 1% are the fiber scaffold composition; the biocompatible material is preferably polycaprolactone, The nanomaterial is preferably single-layer graphene, and the small molecular compound is melatonin.

[0075] Polycaprolactone is dissolved in a solvent 10 times the weight of the composition, and then graphene and melatonin are added and mixed thoroughly to obtain a composition solution capable of forming a fibrous film. The solvent is preferably dichloromethane.

[0076] After removing bubbles from the above-mentioned graphene and melatonin composition solution with an ultrasonic machine, inject it into the injector, output it at a flow rate of 0.1ml / min, and spray it onto a receiving plate with a length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com