Method for measuring uncertainty of industrial CT geometric dimension based on spherical die body

A technology for measuring uncertainty and geometric dimensions, applied to measuring devices, instruments, and using wave/particle radiation, etc., can solve problems that have not been unanimously recognized, and achieve the effect of improving measurement accuracy and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

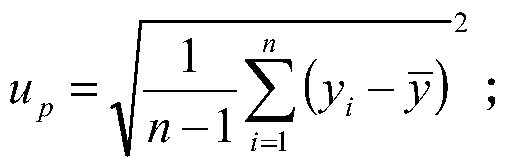

[0030] A method for measuring uncertainty of industrial CT geometric dimensions based on a spherical phantom, comprising the following steps:

[0031] S1: The ball model is sent to the metrology department for calibration and inspection before use and is used as the workpiece to be inspected, and a calibration certificate is obtained. , zirconium dioxide or stainless steel.

[0032] S2: Use industrial CT to scan and reconstruct the inspected workpiece multiple times, and the number of scans is not less than 5 times.

[0033] A complete industrial CT measurement process includes the following steps: First, the scanning and reconstruction of the sample, X-ray transillumination of the sample, affected by the difference in the structure and composition of the sample, resulting in different degrees of attenuation of X-rays, forming a group on the detector. Bright and dark projection related to the sample structure; the turntable rotates synchronously to collect a large number of 2...

Embodiment 2

[0045] The same parts of this embodiment and the first embodiment will not be repeated, and the differences are:

[0046] A ball model composed of two silicon nitride ceramic balls with grade G10 was selected as the research object to evaluate the uncertainty of industrial CT measurement. The advantages of choosing the silicon nitride ceramic ball group model are: high precision, high strength, high hardness, low cost, easy calibration, easy fitting and measurement, small thermal expansion coefficient, small linear attenuation coefficient, ball center distance resistance to threshold fluctuations, etc. The selected ball model (that is, the workpiece to be inspected) has passed the metrological verification of the measuring institution before the industrial CT measurement. The calibration certificate shows that the diameter of the ceramic ball is 19.05mm, the distance between the center of the ball is 38.10mm, the G10 level, the calibration test condition: temperature : 20.3°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com