Production and processing technology of corrugated carton

A corrugated box and processing technology, which is applied in the field of corrugated paper products processing, can solve the problems of reduced overall quality of corrugated paper boxes, pattern stains, strong staining of corrugated paper, etc., and achieve the effects of good quality, avoiding damage, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: A production and processing technology of corrugated cardboard boxes. The components of the protective agent in step 3 and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0046] Step 1, cutting, cutting the corrugated paper raw material to obtain corrugated cardboard;

[0047] Step 2, printing, transfer the cut corrugated cardboard to the printing machine, select the graphic printing plate, print the corrugated cardboard, and get the printed matter;

[0048] Step 3, spraying the protective agent: spray the protective agent on the side of the printed matter containing the printed pattern, and after it is completely dry, the coated semi-finished product is obtained;

[0049] Step 4, creasing and slotting, the coated semi-finished product is folded to form longitudinal and transverse indentations by the creasing wheel, and the incision line is marked by pre-molding, and the dried coated semi-finished p...

Embodiment 2-5

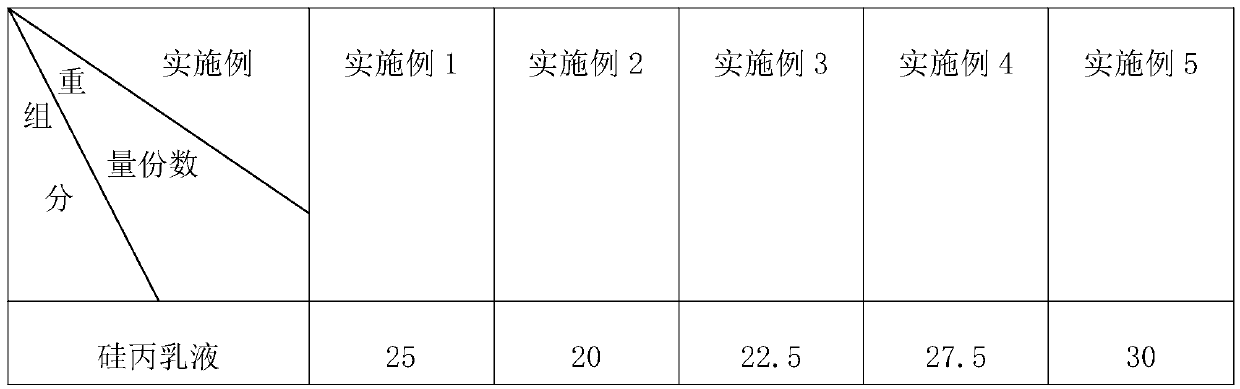

[0053] Example 2-5: A production and processing process of corrugated cardboard boxes. The difference from Example 1 is that the components of the protective agent in Step 3 and their corresponding parts by weight are shown in Table 1.

[0054] Components and parts by weight of protective agent in step 3 in Table 1 embodiment 1-5

[0055]

[0056]

Embodiment 6

[0057] Embodiment 6: A production and processing technology of corrugated cardboard boxes. The difference from Embodiment 1 is that the quality of sodium starch phosphate in the protective agent in step 3 is replaced by sodium polyacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com