Method for regulating and controlling boron element distribution state in 9Cr3W3CoB heat-resistant steel for ultra-supercritical unit

An ultra-supercritical unit and element distribution technology, which is applied in the field of thermal deformation, can solve problems such as hindering the optimal distribution of B elements, and achieve the effects of grain refinement, delaying the decline in toughness, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the present embodiment, the chemical composition of 9Cr3W3CoB ultra-supercritical heat-resistant steel is:

[0035] C:0.11%;Cr:9.02%;W:2.99%;Co:3.05%;Cu:0.88%;B:0.015%;Mn:0.46%;Nb:0.073%;V:0.19%;N:0.006%; Si: 0.27%; Ti: 0.015%; Al: 0.013%; P: 0.012%; S: 0.007%; O: 0.002%;

[0036] In the present embodiment, the method for controlling the distribution state of boron in 9Cr3W3CoB heat-resistant steel for ultra-supercritical units is as follows:

[0037] (1) Heat the workpiece at 400°C / h to 1150°C and keep it warm for 1.5h;

[0038] (2) 6-pass rolling is carried out on the workpiece at 1150°C, and the deformation in a single pass is controlled at 10%, so that the final deformation of the workpiece reaches 60%;

[0039] (3) Cool the workpiece to room temperature in air.

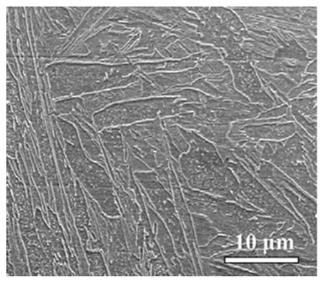

[0040] like figure 1 As shown, BN and other borides in the steel are all dissolved, and the B element redissolves back into the matrix.

[0041] The grain size of the ultra-supercritical heat-resis...

Embodiment 2

[0043] In the present embodiment, the chemical composition of 9Cr3W3CoB ultra-supercritical heat-resistant steel is:

[0044] C:0.11%;Cr:9.02%;W:2.99%;Co:3.05%;Cu:0.88%;B:0.015%;Mn:0.46%;Nb:0.073%;V:0.19%;N:0.006%; Si: 0.27%; Ti: 0.015%; Al: 0.013%; P: 0.012%; S: 0.007%; O: 0.002%;

[0045] In the present embodiment, the method for controlling the distribution state of boron in 9Cr3W3CoB heat-resistant steel for ultra-supercritical units is as follows:

[0046] (1) Heat the workpiece at 400°C / h to 1150°C and keep it warm for 2h;

[0047] (2) 6-pass rolling is carried out on the workpiece at 1150°C, and the deformation in a single pass is controlled at 15%, so that the final deformation of the workpiece reaches 90%;

[0048] (3) Air-cool the workpiece to room temperature;

[0049] (4) Temper at 750°C for 1.5h, then air cool to room temperature.

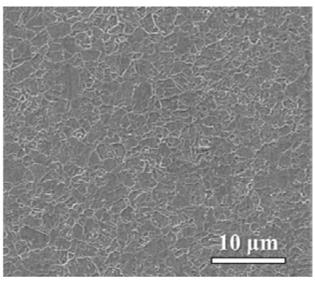

[0050] like figure 2 As shown, all BN and other borides in the steel are dissolved, and the B element dissolves back into the m...

Embodiment 3

[0053] In the present embodiment, the chemical composition of 9Cr3W3CoB ultra-supercritical heat-resistant steel is:

[0054] C:0.11%;Cr:9.02%;W:2.99%;Co:3.05%;Cu:0.88%;B:0.015%;Mn:0.46%;Nb:0.073%;V:0.19%;N:0.006%; Si: 0.27%; Ti: 0.015%; Al: 0.013%; P: 0.012%; S: 0.007%; O: 0.002%;

[0055] In the present embodiment, the method for controlling the distribution state of boron in 9Cr3W3CoB heat-resistant steel for ultra-supercritical units is as follows:

[0056] (1) Heat the workpiece at 400°C / h to 1150°C and keep it warm for 1.5h;

[0057] (2) 6-pass rolling is carried out on the workpiece at 1150°C, and the deformation in a single pass is controlled at 15%, so that the final deformation of the workpiece reaches 90%;

[0058] (3) Air-cool the workpiece to room temperature;

[0059] (4) Aging the workpiece at 800°C for 300h, and air cooling to room temperature.

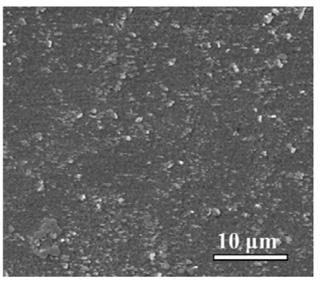

[0060] like image 3 As shown, BN did not re-nucleate and grow, and the Laves phase was fine and dispersed, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com