Purification method of lithium bis(oxalato) borate and lithium bis(oxalato)borate

A technology of lithium bis-oxalate borate and purification method, which is applied in chemical instruments and methods, compounds containing periodic table Group 3/13 elements, electrochemical generators, etc. Battery-level use requirements, affecting the quality of lithium bis-oxalate borate, etc., to achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example is used to illustrate a method for purifying lithium bisoxalate borate disclosed by the present invention.

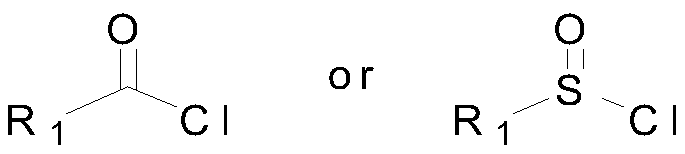

[0027] First, the purity is 300 grams of bisoxalate lithium borate crude product (purity 97%, moisture 5000ppm) and 2000 grams of ethyl acetate are mixed and dissolved and filtered, and the filtrate is transferred to the reaction flask, and then 49 grams of thionyl chloride are added dropwise to the reaction flask (The molar ratio with water is 5:1), after the dropwise addition, heat to 45°C, stir and react for 3 hours, then lower the temperature, transfer the reaction solution to a concentrated bottle, then vacuumize and distill the solvent off, and concentrate to the total weight Cool down and add dichloromethane to 400 grams, filter to obtain a solid semi-finished product and transfer it to a crystallization bottle, add a mixed solution of 900 grams of dichloromethane and ethyl acetate (mass ratio 10:1) (the amount of mixed solvent is the crude pro...

Embodiment 2

[0029] This example is used to illustrate a method for purifying lithium bisoxalate borate disclosed by the present invention.

[0030] First, the purity is 300 grams of bisoxalate lithium borate crude product (purity 97%, moisture 0.5%) is filtered after mixing and dissolving with 1000 grams of acetonitrile, and the filtrate is transferred to the reaction flask, and then 65 grams of acetyl chloride (with water) are added dropwise to the reaction flask. The molar ratio is 10:1), heated to 55°C after the dropwise addition, stirred and reacted for 4 hours, then lowered the temperature, transferred the reaction solution to a concentrated bottle, then vacuumed and distilled off the solvent, concentrated to a total weight of 380 grams Cool down and add normal hexane, filter to obtain solid semi-finished product and transfer in the crystallization bottle, add the mixed solution of 1200 grams of normal hexane and acetonitrile (mass ratio 5:1) (the amount of mixed solvent is 4 times of...

Embodiment 3

[0032] This example is used to illustrate a method for purifying lithium bisoxalate borate disclosed by the present invention.

[0033]First, the purity is 300 grams of bisoxalate lithium borate crude product (purity 97%, moisture 0.5%) and 1500 grams of tetrahydrofuran (THF) are mixed and dissolved and filtered, and the filtrate is transferred to the reaction flask, and then 117 grams of methyl chloroformate ( The molar ratio with water is 15:1), after the dropwise addition is completed, it is heated to 66° C., and the temperature is lowered after stirring for 5 hours. Cool down and add toluene at 390 grams, filter to obtain a solid semi-finished product and transfer it to a crystallization bottle, add a mixed solution of 1800 grams of toluene and tetrahydrofuran (mass ratio 15:1) (the amount of mixed solvent is 6 times the weight of the crude product of lithium bisoxalate borate), and heat To the reflux state, keep reflux for 6 hours and then cool down, let it slowly crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com