Lithium air battery and manufacturing method thereof

A technology for a lithium-air battery and a manufacturing method, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as hindering charge transfer, high voltage, battery deterioration, etc., and achieve the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

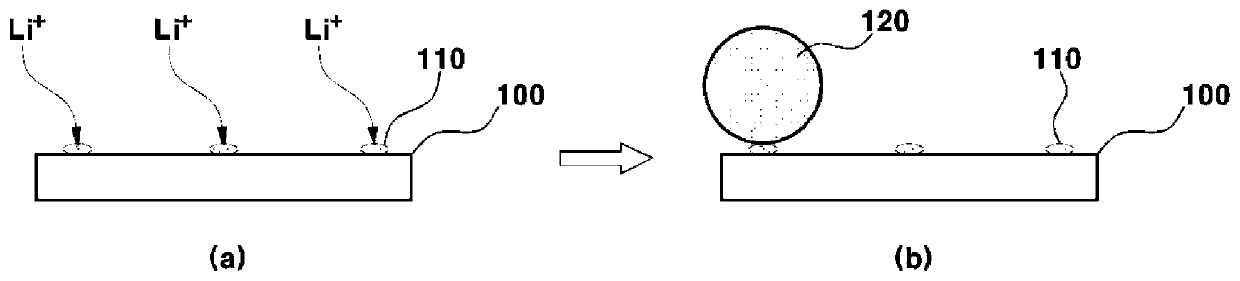

Problems solved by technology

Method used

Image

Examples

Embodiment

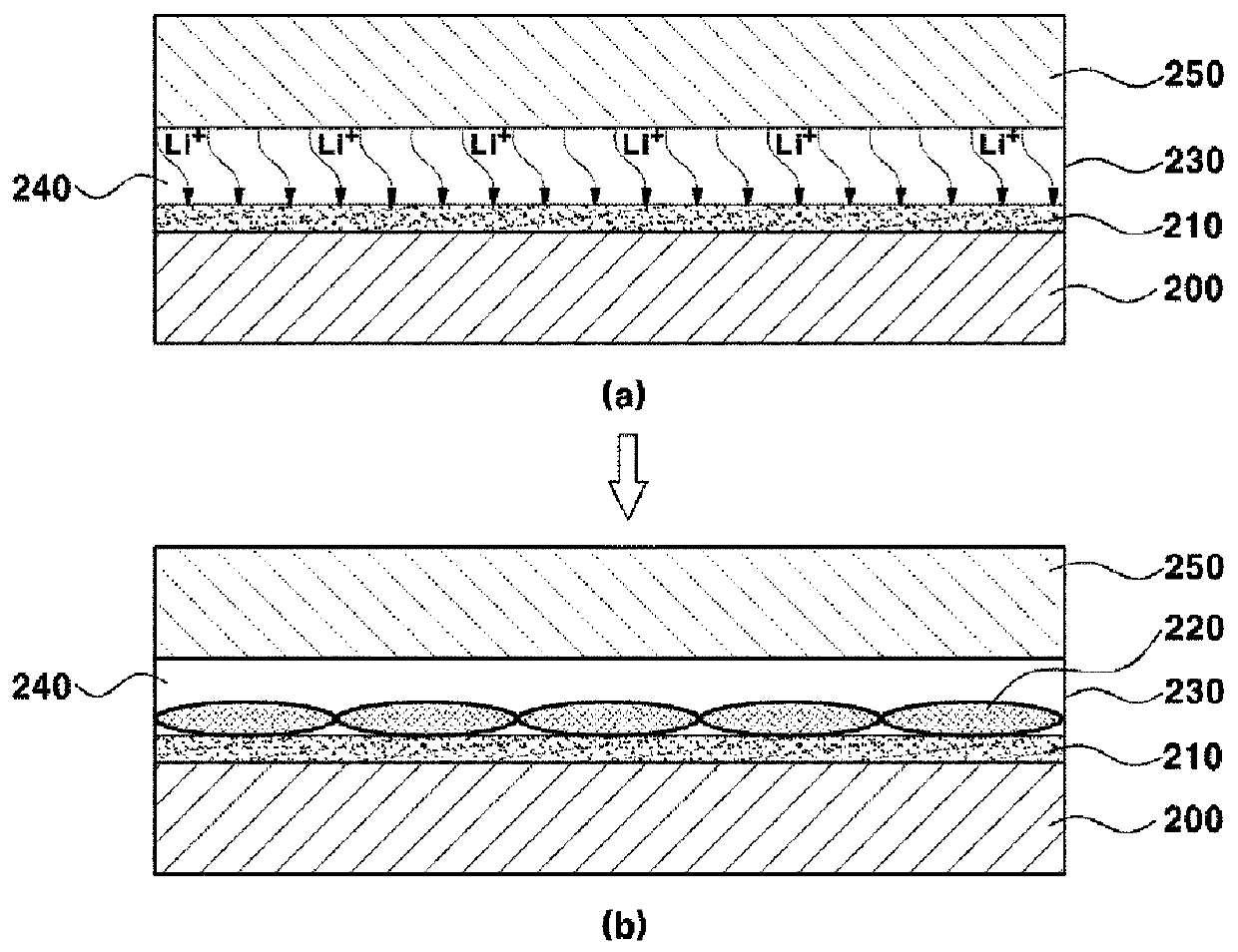

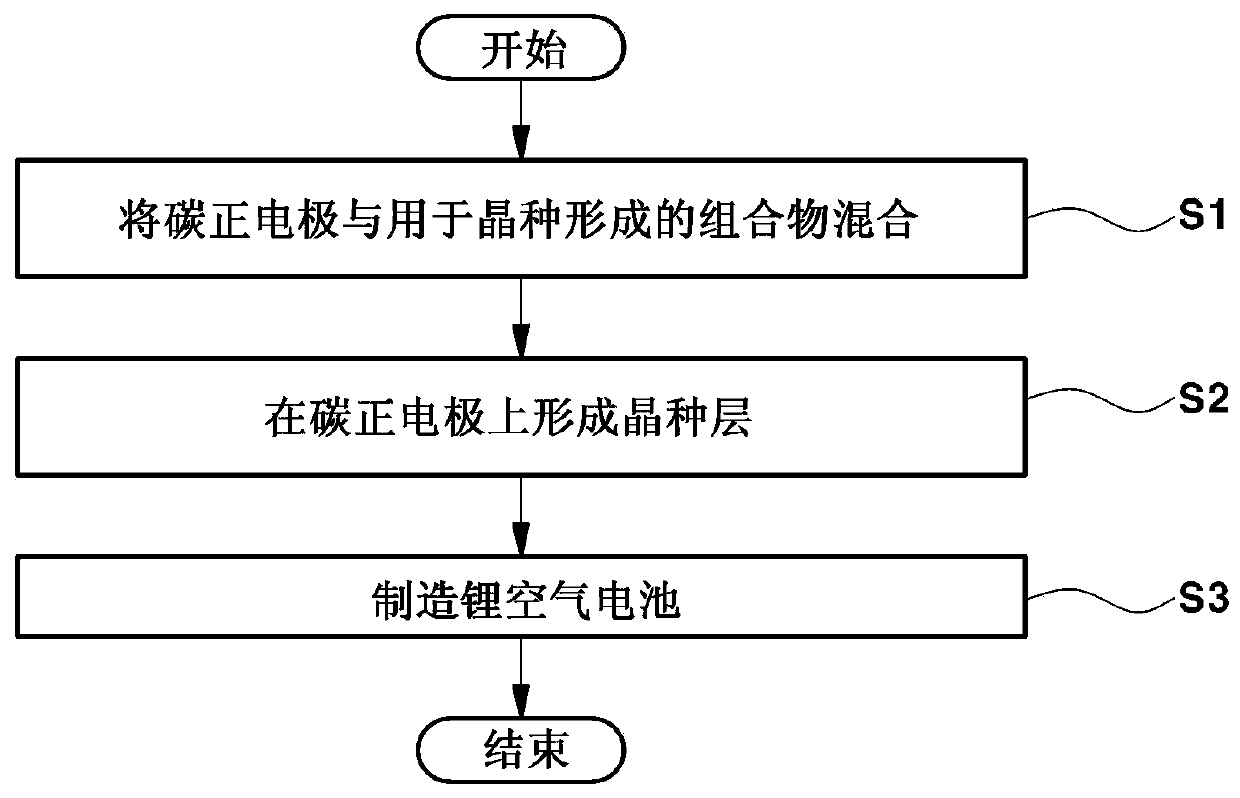

[0093] (1) Form a seed layer on the carbon positive electrode

[0094] 1M LiNO 3 (lithium-based compound) was mixed with dimethylacetamide (DMAc) to prepare a composition for seed formation. Graphite carbon and polytetrafluoroethylene (PTFE) binder were dry-blended at a weight ratio of 9:1, and then self-contained electrodes were used to fabricate carbon positive electrodes. At this time, the thickness of the carbon positive electrode was 200 μm, and the amount of carbon material loaded to make the carbon positive electrode was 5 mg / cm 2 .

[0095] The carbon positive electrode is soaked in the composition for seed crystal formation, and the pressure of 2 bar, 0.5mA / cm 2 A current was supplied to the composition for seed crystal formation at a current of 2.0 for 10 hours to perform electrolysis. At this time, the charge-discharge cycle was repeated five times to form a seed layer having a thickness of 2 to 3 nm on one surface of the carbon positive electrode.

[0096] (2)...

experiment Embodiment 1

[0102] Experimental Example 1: Composition analysis of the seed layer on the carbon positive electrode.

[0103] Measurement was performed using X-ray photoelectron spectroscopy (XPS) to analyze the composition of the seed layer formed on the carbon positive electrode manufactured according to the example. A pure carbon positive electrode (Pristine) and a carbon positive electrode having a seed layer thereon manufactured according to the above-mentioned examples were measurement samples. The results are shown in Figure 4 to Figure 7 middle.

[0104] Figures 4 to 7 is a graph showing the binding energies of elements (carbon, nitrogen, oxygen, and lithium) detected from the seed layer formed on the carbon positive electrode according to the example. see Figure 4 , it can be seen that the carbon element has a peak at about 285eV. However, since the carbon element of the carbon positive electrode according to the embodiment has a lower strength than that of the pure carbon...

experiment Embodiment 2-1

[0106] Experimental Example 2-1: Analysis of gas in a lithium-air battery during initial charge and discharge.

[0107] By using a differential electrochemical mass spectrometer (DEMS), a gas analyzer, the charge and discharge potentials of the lithium-air batteries fabricated according to Examples and Comparative Example 1 and the gas generated therein during initial charge and discharge thereof, such as O 2 and CO 2 amount of gas. At 2 bar pressure, 0.5mA / cm 2 Under the conditions of current of 2.0 V and voltage of 2.0 V, current was supplied to the lithium-air battery in an oxygen atmosphere for 120 minutes to perform each charging and discharging operation. The results are shown in Figures 8A to 12B middle.

[0108] Figure 8A , 9A 10A and 10A are graphs showing charge and discharge potentials of lithium-air batteries manufactured according to Examples after being charged and discharged once, three times and five times, respectively. refer to Figure 8A , it can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com