Hydrogen isotope crystallization height and surface roughness interference measurement device and method

A technology of surface roughness and interferometric measurement, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of poor contrast of interference fringes, measurement interference, and the influence of interference microscope measurement accuracy, etc., and achieve high precision and simple measurement methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

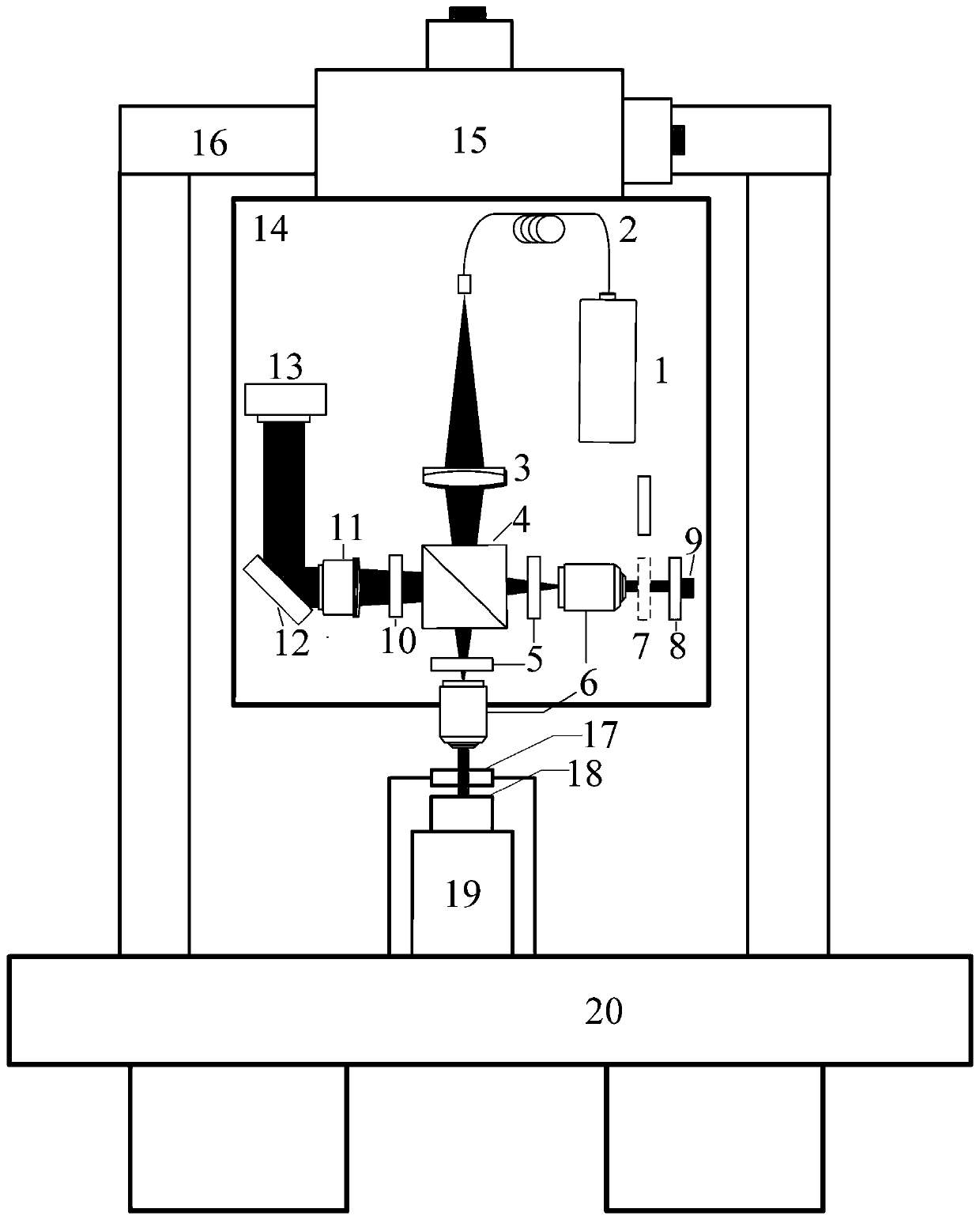

[0041] Such as figure 1As shown, a hydrogen isotope crystallization height and surface roughness interferometric measurement device includes an interferometric system, a displacement system and a computer processing module. The whole device is fixed on the marble platform 20.

[0042] In the interferometric system, the short-coherent linearly polarized light generated by the fiber laser 1 exits through the single-mode polarization-maintaining fiber 2, and the diverging spherical wave is converted into a converging spherical wave by the doublet lens 3 and split by the polarization beam splitter prism 4. The vertically polarized light is reflected by the polarizing beam splitter prism 4 and passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com