Creeping formwork suspension

A technology of climbing formwork and suspension seat, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of affecting the beauty of the wall, poor load-bearing capacity, low construction efficiency, etc. Avoid shaking, improve safety, and stabilize the base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

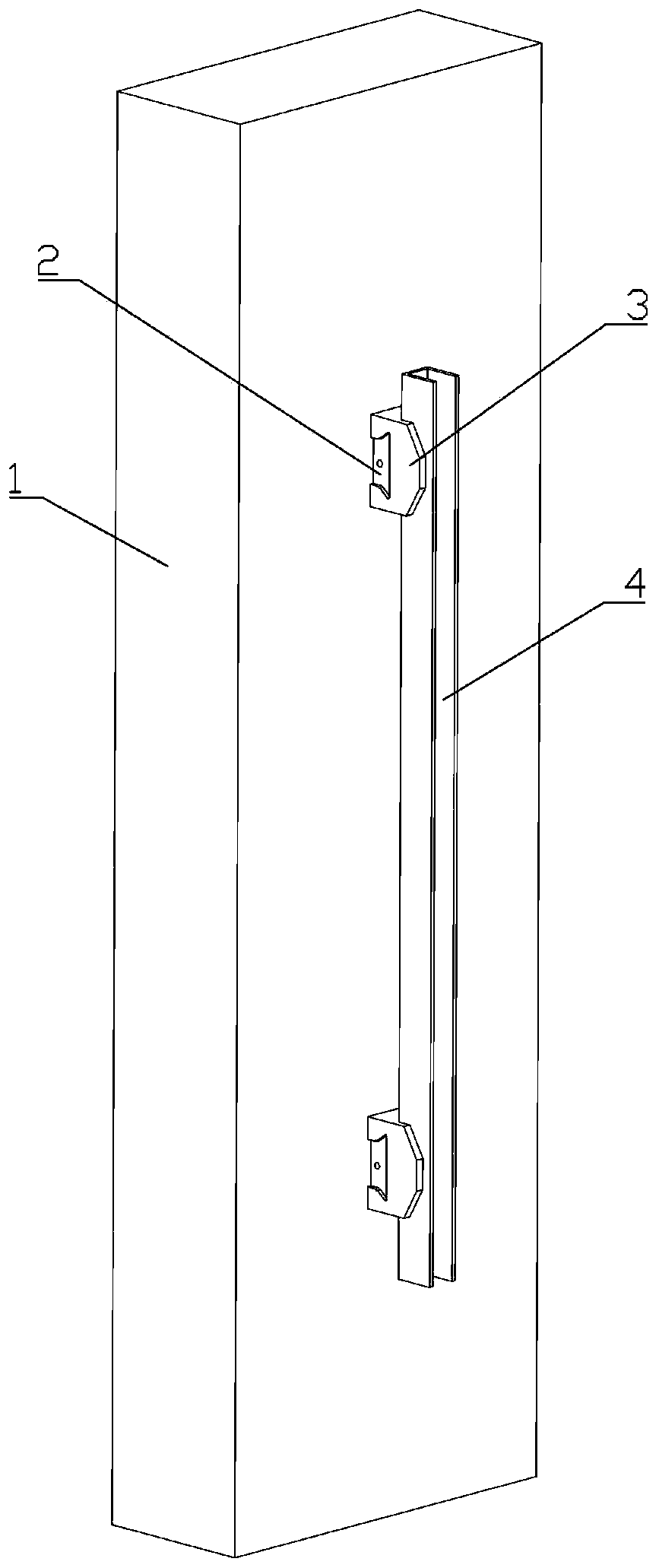

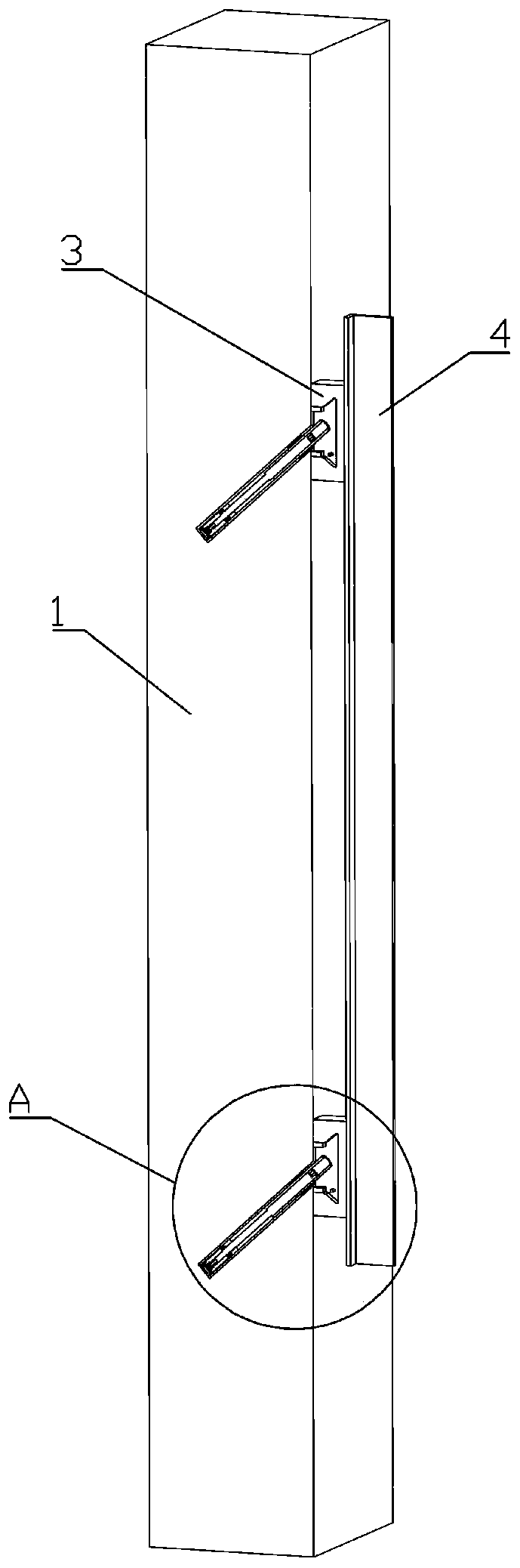

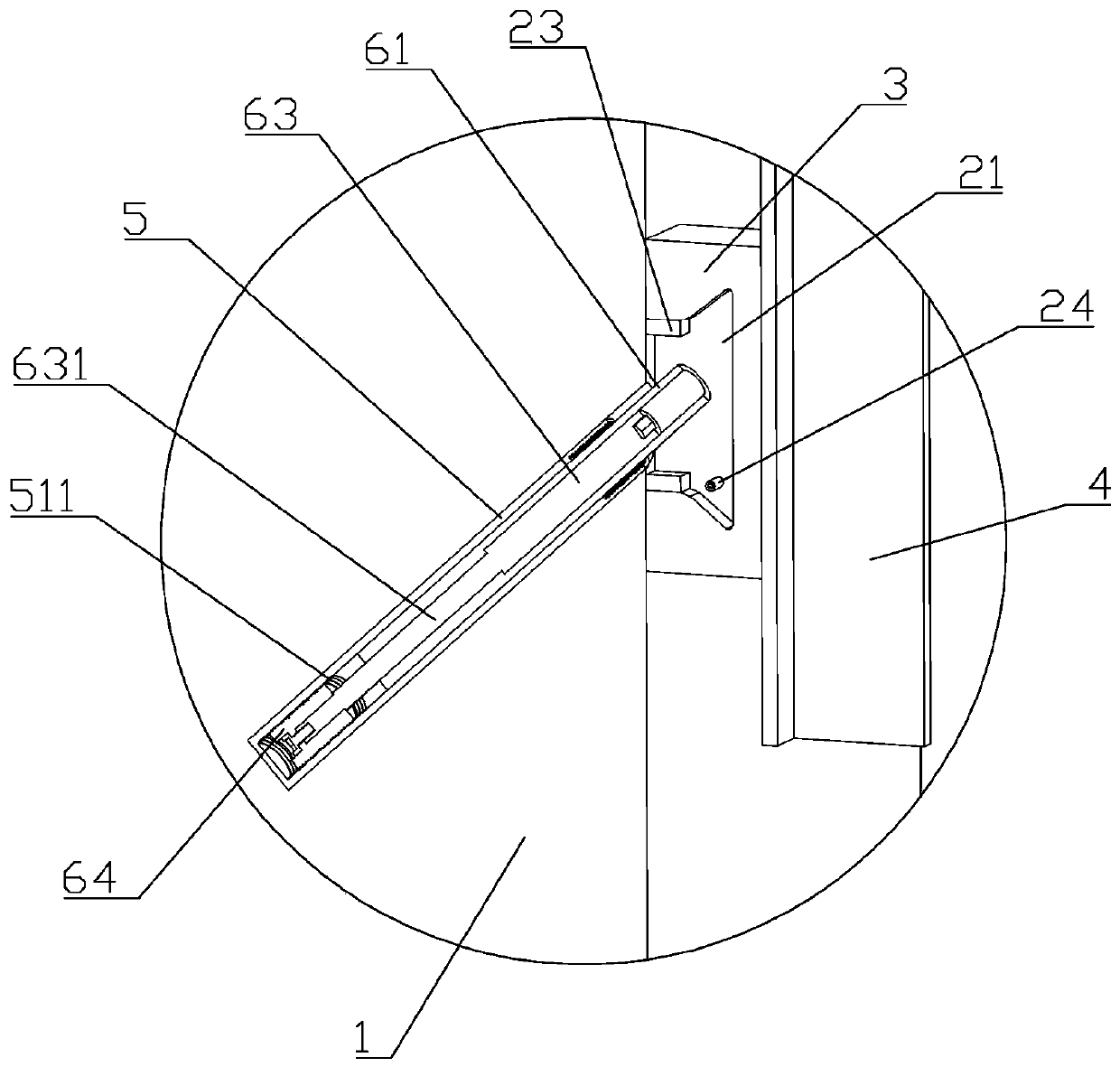

[0029] Such as Figure 1~5 As shown, a climbing formwork suspension includes a pre-embedded pipe 5 obliquely pierced in the wall 1, a fixed core is installed in the pre-embedded pipe 5, a suspension seat is installed on the fixed core, and a base is installed on the suspension seat 3. The slide rail 4 is installed on the base 3. The slide rail 4 is used to install the climbing formwork. The fixed core includes the first connecting rod 61. One end of the first connecting rod 61 is hinged with the base 3, and the other end slides through the embedded pipe 5, wherein the first connecting rod 61 is in clearance fit with the embedded pipe 5, the fit gap between the first connecting rod 61 and the embedded pipe 5 is 0.5 mm to 1 mm, and the first connecting rod 61 opens a first blind hole, The bottom of the first blind hole is provided with a first through hole, a second connecting rod 63 is slidably pierced in the first blind hole, a third connecting rod 631 is slidably pierced in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com