Simple preparation method of Ag-Au composite nanometer periodic structure with high SERS activity

A periodic structure and nanotechnology, applied in the field of nanomaterials, can solve problems such as lack of universality, and achieve stable and reliable SERS performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a simple preparation method of an Ag-Au composite nano-periodic structure with high SERS activity, comprising the following steps:

[0029] Step 1, depositing a layer of silver film on the channel surface of the single-pass anodized aluminum template;

[0030] Step 2, forming discontinuous silver nanoparticles on the bottom of the channel and the walls of the pores through the high-temperature confined spheroidization process of the metal film to obtain a template-based silver nanoparticle array substrate;

[0031] Step 3, immersing the template-based silver nanoparticle array substrate obtained in step 2 in a gold ion solution for different times to obtain an Ag-Au composite nano-periodic structure;

[0032] Step 4, soak the Ag-Au composite nano-periodic structure obtained in step 3 in different molecular solutions to be tested, take it out after 30 minutes, rinse with ultrapure water, and blow dry with nitrogen to obtain the sample to be tested....

Embodiment 1

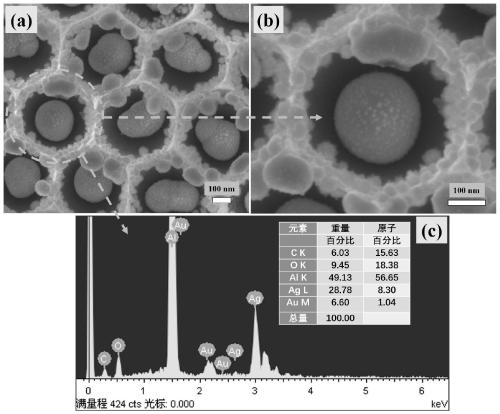

[0038] In this example, a single-pass anodic alumina template with a pore diameter of 450 nm and a pore depth of 500 nm was selected to prepare an initial silver nanoparticle array. The thickness of the silver film deposition was 35 nm, the spheroidization temperature was 400 ° C, and the spheroidization time was 2 hours. After 5 minutes of substitution reaction, Ag was obtained. -Au composite nanoperiodic structures.

[0039] Specific steps are as follows:

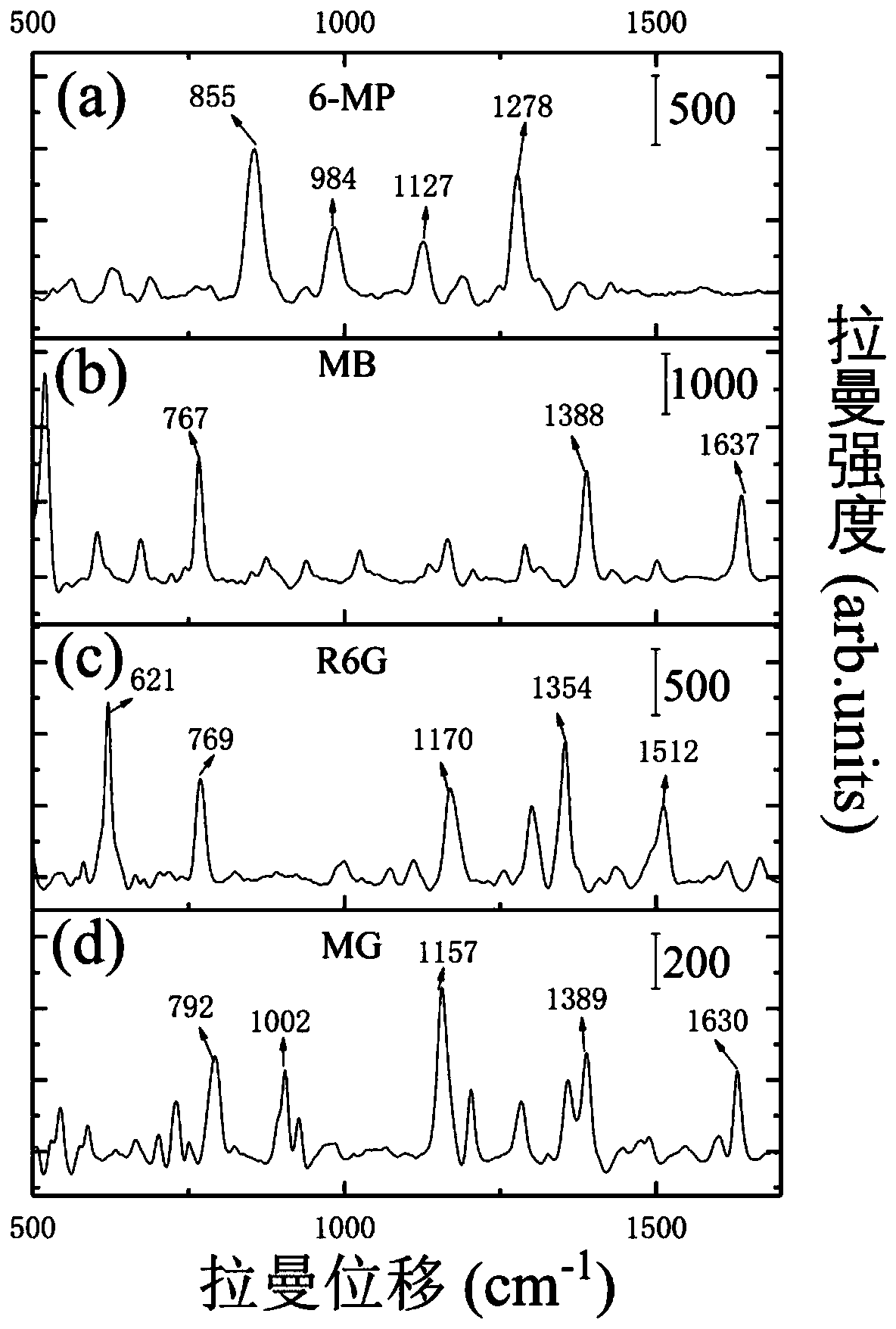

[0040]First, a 35nm silver film is deposited on the channel surface of the single-pass anodized aluminum template, and then discontinuous silver nanoparticles are formed on the bottom and wall of the channel through a high-temperature confined spheroidization process to obtain a template-based silver nanoparticle array substrate ; The obtained template-based silver nanoparticle array substrate was soaked in the gold ion solution for 5 minutes to react. After taking it out, it was washed with ultrapure water and dried by e...

Embodiment 2

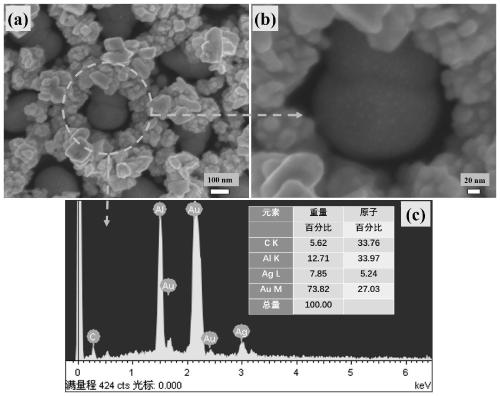

[0042] The difference between this embodiment 2 and embodiment 1 is that the substitution reaction time is 15min, and the concentration of the four kinds of detection molecules is 10 -6 M.

[0043] Specific steps are as follows:

[0044] First, a 35nm silver film is deposited on the channel surface of the single-pass anodized aluminum template, and then discontinuous silver nanoparticles are formed on the bottom and wall of the channel through a high-temperature confined spheroidization process to obtain a template-based silver nanoparticle array substrate ; Soak the obtained template-based silver nanoparticle array substrate in the gold ion solution for 15 minutes to react, take it out, wash it with ultrapure water, and dry it with electric heat to obtain the Ag-Au composite nano-periodic structure; finally, the prepared Ag- After 30 days of preservation, the Au composite nano-periodic structure was soaked in different concentrations of 6-Mercaptopurine (6-MP) and methylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com