Method for preparing silver conductive adhesive by in situ synthesis

An in-situ synthesis and conductive adhesive technology, which is applied in the field of conductive adhesive, can solve the problems of complex post-treatment process, difficulty in large-scale production, and harsh conditions, and achieve the effects of low cost, simple preparation method, and uniform reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

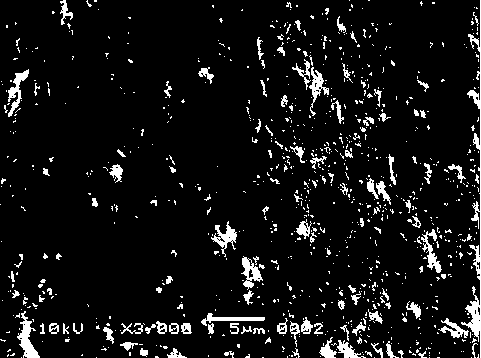

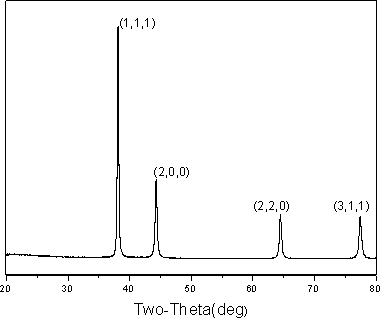

Image

Examples

Embodiment 1

[0031] (1) Prepare a 1mol / L silver nitrate solution, disperse the silver nitrate in a mixed solution of 10ml of ethanol and 10ml of ethylene glycol, and make solution 1;

[0032] (2) Add epoxy resin (20% of the mass of silver nitrate solution) to solution 1, stir evenly, put it in a microwave oven, and irradiate it under microwave with a frequency of 2.45GHZ and a power of 320W for 2 minutes. Stand for one hour to remove the ethanol in the solution;

[0033] (3) Add 3% methyltetrahydrophthalic anhydride (curing agent) and 0.1% 2-ethyl-4-methylimidazole (curing accelerator) to the solution after standing, mix well, and the curing condition is 80 °C, 2h; 160°C, 4h, to obtain the conductive adhesive of the present invention.

Embodiment 2

[0035] (1) Prepare a 2mol / L silver nitrate solution, disperse the silver nitrate in a mixed solution of 5ml of ethanol and 25ml of glycerol to form solution 1;

[0036] (2) Add epoxy resin (25% of the mass of silver nitrate solution) to solution 1, stir evenly, put it in a microwave oven, and irradiate it for 3 minutes under a microwave with a frequency of 2.45GHZ and a power of 320W. Stand for one hour to remove the ethanol in the solution;

[0037] (3) Add 4% methylhexahydrophthalic anhydride (curing agent) and 0.3% 2-ethyl-4-methylimidazole (curing accelerator) to the solution after standing, mix well, and the curing condition is 80 °C, 2h; 160°C, 4h, to obtain the conductive adhesive of the present invention.

Embodiment 3

[0039] (1) Prepare a 4mol / L silver nitrate solution, disperse the silver nitrate in a mixed solution of 10ml of ethanol and 30ml of ethylene glycol, and make solution 1;

[0040] (2) Add epoxy resin (30% of the mass of silver nitrate solution) to solution 1, stir evenly, place in a microwave oven, irradiate for 4.5 minutes under a microwave with a frequency of 2.45GHZ and a power of 320W, at 80°C Stand for one hour to remove the ethanol in the solution;

[0041] (3) Add 5% methyltetrahydrophthalic anhydride (curing agent) and 0.5% 2,4,6-tris(dimethylaminomethyl)phenol (curing accelerator) to the solution after standing, and mix Uniform, curing conditions are 80°C, 2h; 160°C, 4h, to obtain the conductive adhesive of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com