Ultra-high-density twinned titanium and its preparation method

An ultra-high density, twinning technology, applied in the preparation of ultra-high-density twinned titanium, can solve problems such as the lack of nano-twinned strengthening and toughening effect, the unsatisfactory limit density, and the difficulty in obtaining high-density twinning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

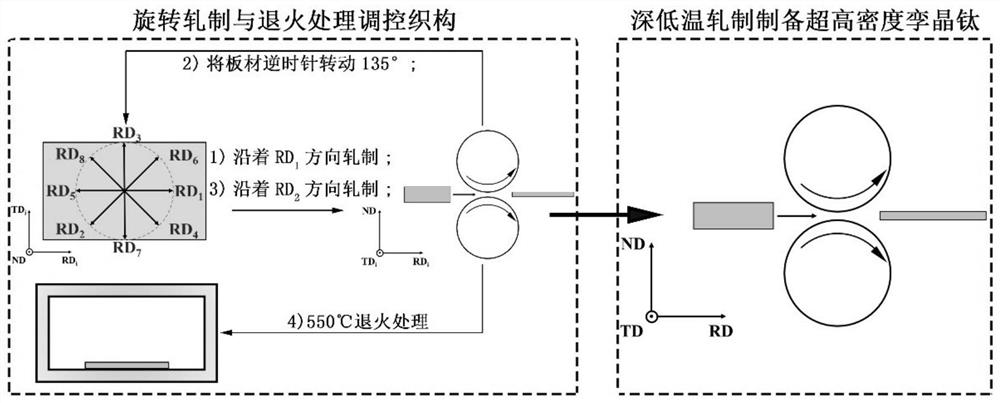

[0022] like figure 1 As shown, the following examples involve a two-step process including: rotary rolling and annealing treatment to control the texture, and deep low temperature rolling to prepare ultra-high-density twinned titanium, wherein:

[0023] A sample of 15 mm x 60 mm x 100 mm was cut from the obtained plate, and the surface and corners were polished for treatment. like figure 1 Shown is the process flow chart for preparing ultra-high-density twinned titanium. The specific implementation steps are as follows: 1) along the plate RD 1 2) Rotate the plate 135° counterclockwise after rolling, at this tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com