Organic-inorganic composite agriculture and forestry water-retaining agent and preparation method thereof

A composite, water-retaining agent technology, applied in the direction of organic fertilizers, agricultural machinery and implements, chemical instruments and methods, etc., can solve the problem that water-retaining agents cannot meet the needs of water and nutrients at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

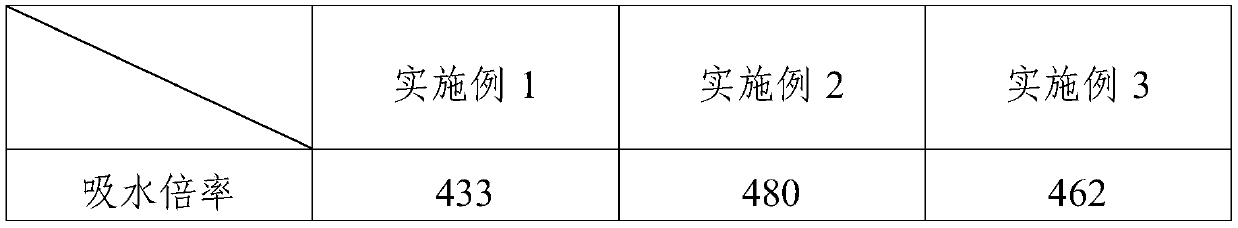

Embodiment 1

[0036] An organic-inorganic composite agricultural and forestry water-retaining agent is prepared from the following raw materials in parts by weight:

[0037] 32 parts of straw cellulose, 16 parts of modified vermiculite, 8 parts of humic acid, 90 parts of potassium hydroxide solution with a mass concentration of 5%, 5 parts of N,N'-methylenebisacrylamide, 2 parts of potassium persulfate, 60 parts of 5% sodium hydroxide solution, 110 parts of 2% urea solution, 60 parts of acrylic acid solution with a neutralization degree of 80%, 5 parts of γ-polyglutamic acid, and 2% carbodiimide solution 25 parts, 10 parts of 1,4-butanediamine, 0.5 parts of a buffer composed of citric acid and trisodium citrate at a mass ratio of 1:1, and 80 parts of deionized water.

[0038] The preparation method of straw cellulose is as follows:

[0039] Cut corn stalks and add them to water, boil for 3 hours, dry them, pulverize them with a grinder, add them to dilute nitric acid with a mass fraction o...

Embodiment 2

[0045] An organic-inorganic composite agricultural and forestry water-retaining agent is prepared from the following raw materials in parts by weight:

[0046] 40 parts of straw cellulose, 10 parts of modified vermiculite, 5 parts of humic acid, 100 parts of 8% potassium hydroxide solution, 4 parts of N,N'-methylenebisacrylamide, 1 part of potassium persulfate, 60 parts of 3% sodium hydroxide solution, 120 parts of 2% urea solution, 80 parts of acrylic acid solution with a neutralization degree of 80%, 6 parts of γ-polyglutamic acid, and 5% carbodiimide solution 25 parts, 12 parts of 1,4-butanediamine, 0.5 parts of a buffer composed of citric acid and trisodium citrate at a mass ratio of 1:1, and 80 parts of deionized water.

[0047] The preparation method of straw cellulose is as follows:

[0048] Cut corn stalks and add them to water, boil for 5 hours, dry them, pulverize them with a grinder, add them to dilute nitric acid with a mass fraction of 15%, heat up to 60°C for 60...

Embodiment 3

[0054] An organic-inorganic composite agricultural and forestry water-retaining agent is prepared from the following raw materials in parts by weight:

[0055] 35 parts of straw cellulose, 20 parts of modified vermiculite, 6 parts of humic acid, 80 parts of potassium hydroxide solution with a mass concentration of 5%, 5 parts of N,N'-methylenebisacrylamide, 2 parts of potassium persulfate, 60 parts of 5% sodium hydroxide solution, 120 parts of 3% urea solution, 60 parts of acrylic acid solution with a neutralization degree of 80%, 5 parts of γ-polyglutamic acid, and 5% carbodiimide solution 20 parts, 10 parts of 1,4-butanediamine, 0.5 parts of a buffer composed of citric acid and trisodium citrate at a mass ratio of 1:1, and 80 parts of deionized water.

[0056] The preparation method of straw cellulose is as follows:

[0057] Cut corn stalks and add them to water, boil for 5 hours, dry them, pulverize them with a grinder, add them to dilute nitric acid with a mass fraction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com