A 3D printer and method for corner-laying carbon fiber/resin composite products

A resin composite material, 3D printer technology, applied in the direction of additive processing, processing and manufacturing of solid materials and liquid materials, additive processing, etc. problems, to achieve the effect of ensuring the arbitrary angle, good printing effect and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

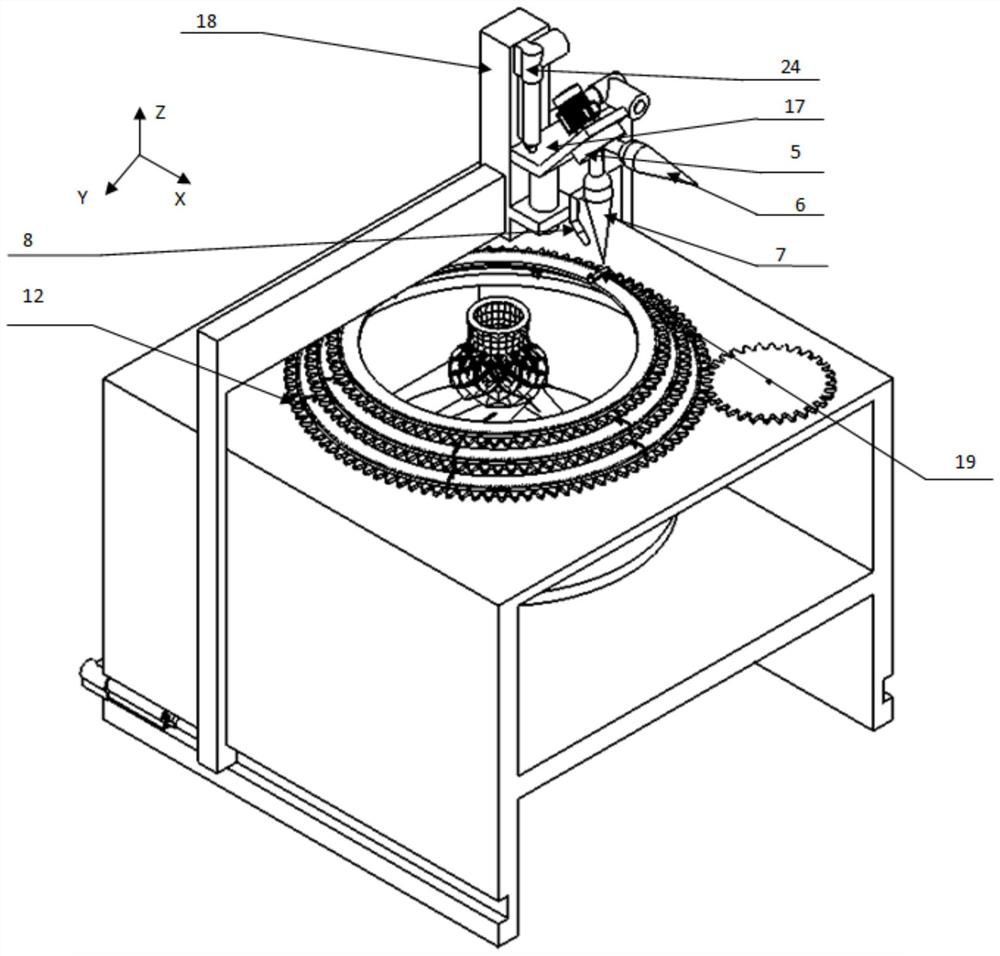

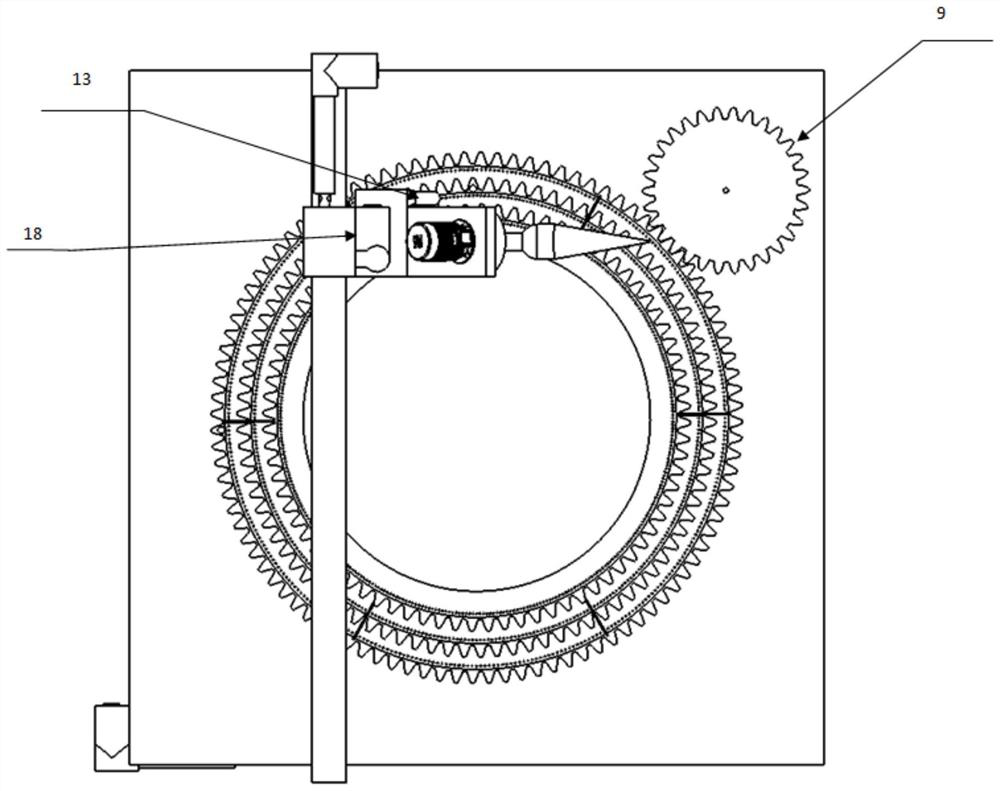

[0037] like Figure 1-3 As shown, a corner laying carbon fiber / resin composite product 3D printer includes: a processing platform, a threaded plate structure 12, and a fiber resin multifunctional nozzle 13;

[0038] The processing platform includes a lifting motor 16, a shaft coupling, a lead screw 21, a worm wheel 22, a worm 23, a thrust bearing, a lifting platform 14, a nozzle moving frame 17, a push-pull motor 24, a processing platform moving frame 18, and the lifting platform 14 passes through The screw 21 is fixed to the lower layer of the processing platform, the worm gear 22 is installed between the thrust bearings and meshed with the worm 23, the worm 23 is connected with the lifting motor 16, the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com