A combined stainless steel welding core coated electrode

A technology of coating electrode and stainless steel, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of thickening of electrode coating, uneven distribution, unstable arc, etc., to reduce redness and Cracking tendency, the effect of improving comprehensive mechanical properties, improving strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

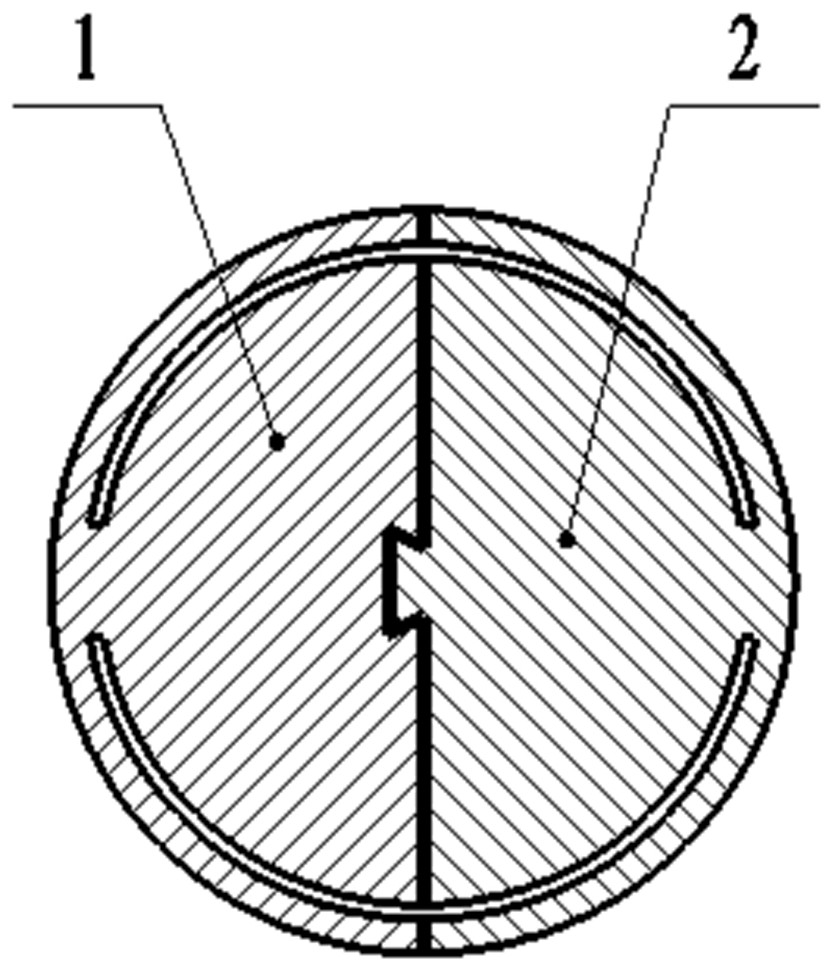

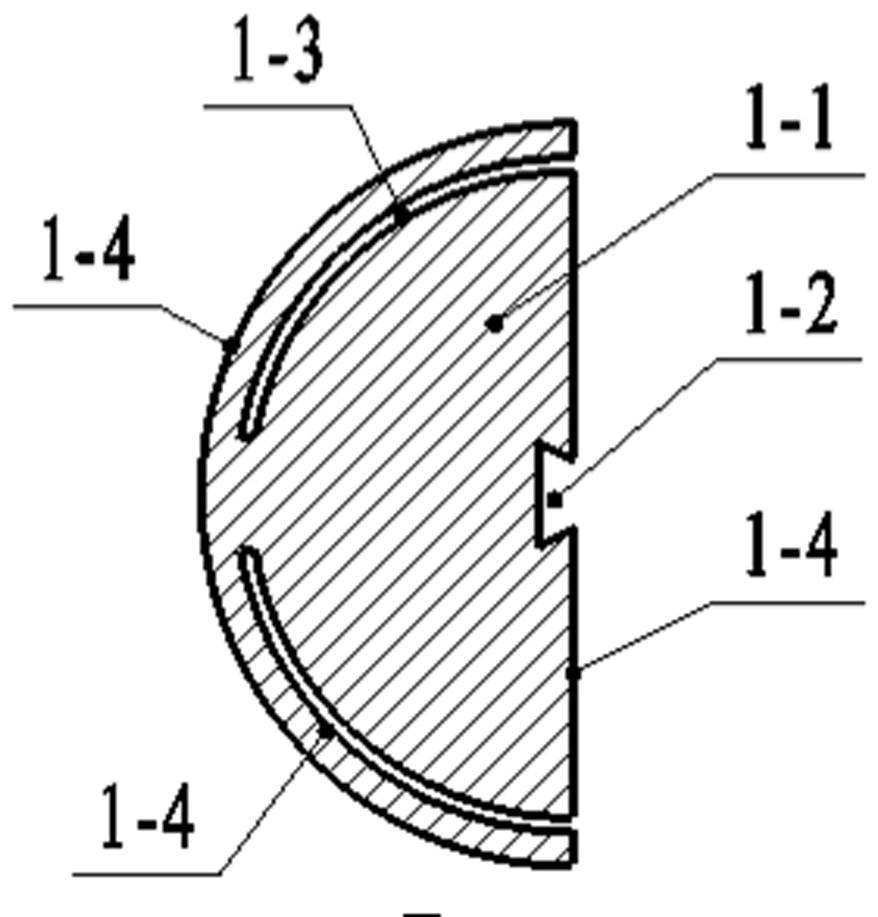

Image

Examples

Embodiment 1

[0037]According to the specific embodiment, the combined stainless steel welding core of the present invention is applied, the core diameter is 3.2 mm, the thickness of the copper plated layer I and the copper plated layer II are 0.05 mm, and the thickness of the nanometer coating is about 0.10 nm. .

Embodiment 2

[0039]According to the specific embodiment, the combined stainless steel welding core of the present invention is applied, the core diameter is 5.0 mm, the thickness of the copper-plated layer I and the copper-plated layer II are 0.08 mm, and the thickness of the nanometer coating is about 0.15 nm. .

Embodiment 3

[0041]According to a specific embodiment, the combined stainless steel welding core of the present invention is applied, the core diameter is 8.0 mm, the thickness of the copper-plated layer I and the copper plated layer II are 0.10 mm, the thickness of the nanometer coating is about 0.20 nm. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com