Forming method of press-in type free forging

A forming method and press-in technology, which is applied in forging/pressing/hammer devices, forging/pressing/hammering machines, manufacturing tools, etc., can solve the problems of high utilization rate of forgings and cracking, and improve the quality of materials. Utilization rate, reduction of blanking weight, and effect of lowering cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

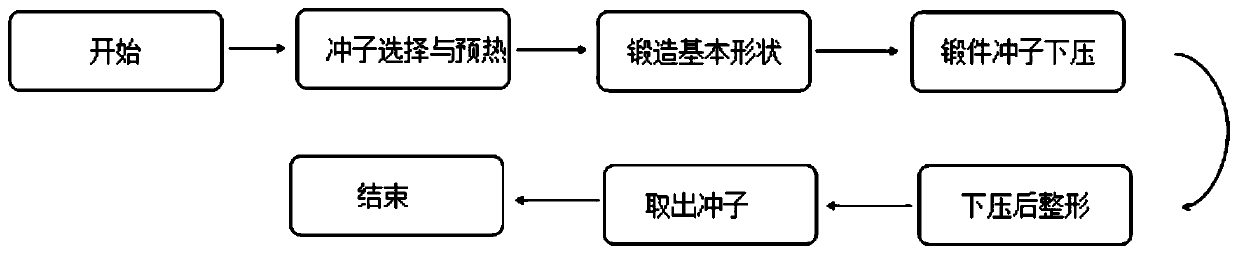

[0021] A forming method of press-in free forging, the specific steps are as follows:

[0022] Step 1. Calculate the deformation process of the forging, select the punch, and taper the punch, and preheat the punch. The preheating temperature of the punch is 380°C;

[0023] Step 2, according to the pre-calculated deformation process and the size requirements of the forging, forging the forging minus the remaining size after the punch is pressed, that is, obtaining the basic shape of the forging;

[0024] Step 3: Determine the pressing position of the punch in the forging and locate it, and press the punch in. The pressing process should be smooth and slow, so as to avoid the temperature rise of the forging caused by severe deformation;

[0025] Step 4: Shaping the forgings until the forging is completed. During the shaping process, the punches pressed in are subject to compressive stress and will gradually discharge the forgings.

[0026] As a further solution of the embodiment...

Embodiment 2

[0028] The weight of the forging without the punch is 365Kg, and the weight of the forging with the punch is 330Kg, saving about 10% of the material. The production process of the press-in punch is introduced below.

[0029] 1. Select the punch: choose the punch of φ160×200, the punch material is H13 (the material grade is 4Cr5MoSiV1, which is a commonly used hot work die steel), and the punch preheating temperature is 400°C (the punch preheating method, electric furnace preheating Oven hold for 60 minutes.)

[0030] 2. Design the shape of the forging before pressing the punch: according to the pressing amount of the punch, reduce the margin of 5mm in the length and width directions of the forging. Consistent with the finished forging.

[0031] 3. Press into the punch: the fitter puts the punch in the selected position, and the placement time should not be too long, and then the equipment exerts pressure on the punch to press the punch into the forging, and the pressing amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com