Preparation method and application of bipyridine functionalized COF loaded palladium nanoparticles

A technology of palladium nanoparticles and bipyridine is applied in the field of preparation of bipyridine functionalized COF-supported palladium nanoparticles, which can solve the problems of low ethylene selectivity and easy deactivation of catalysts, and achieve the effects of long service life and high catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

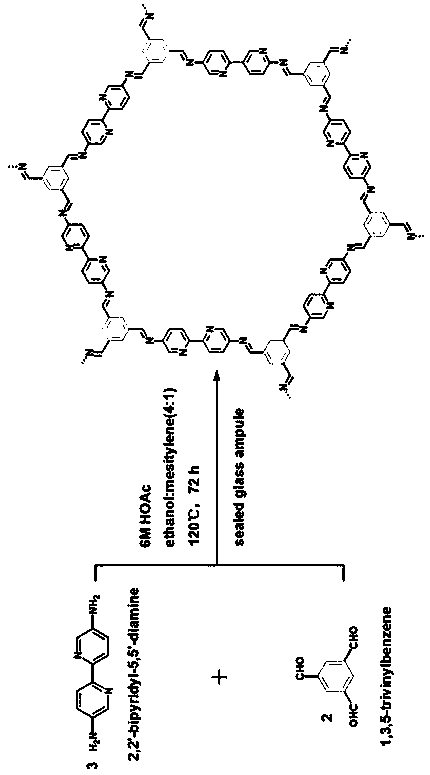

[0022] Embodiment 1: The preparation method of bipyridyl functionalized COF loaded palladium nanoparticles, the specific steps are as follows:

[0023] (1) Dissolve tritylaldehyde and 5,5'-diamino-2,2'-bipyridine in an organic solvent in a high borosilicate glass tube to obtain a mixed solution A, drop by drop in the mixed solution A Add acetic acid aqueous solution to obtain mixed solution B; wherein the organic solvent is a mixed solvent of ethanol and mesitylene; wherein the concentration of tritylaldehyde in mixed solution A is 0.10mol / L, 5,5'-diamino-2,2 The concentration of '-bipyridyl is 0.150mol / L, the volume ratio of ethanol and mesitylene in the organic solvent is 4:1, the concentration of acetic acid aqueous solution is 6.0mol / L, and the volume ratio of acetic acid aqueous solution and organic solvent is 1:5 ;

[0024] (2) Freeze the mixed solution B in the high borosilicate glass tube in step (1) sequentially with liquid nitrogen and vacuumize it with a mechanical...

Embodiment 2

[0030] Embodiment 2: the preparation method of bipyridyl functionalized COF loaded palladium nanoparticles, the specific steps are as follows:

[0031] (1) Dissolve tritylaldehyde and 5,5'-diamino-2,2'-bipyridine in an organic solvent in a high borosilicate glass tube to obtain a mixed solution A, drop by drop in the mixed solution A Add acetic acid aqueous solution to obtain mixed solution B; wherein the organic solvent is a mixed solvent of ethanol and mesitylene; wherein the concentration of tritylaldehyde in mixed solution A is 0.11mol / L, 5,5'-diamino-2,2 The concentration of '-bipyridine is 0.165mol / L, the volume ratio of ethanol and mesitylene in the organic solvent is 3:1, the concentration of acetic acid aqueous solution is 6.0mol / L, and the volume ratio of acetic acid aqueous solution and organic solvent is 1:5 ;

[0032] (2) Freeze the mixed solution B in the high borosilicate glass tube in step (1) sequentially with liquid nitrogen and vacuumize it with a mechanica...

Embodiment 3

[0037] Embodiment 3: The preparation method of bipyridyl functionalized COF loaded palladium nanoparticles, the specific steps are as follows:

[0038] (1) Dissolve tritylaldehyde and 5,5'-diamino-2,2'-bipyridine in an organic solvent in a high borosilicate glass tube to obtain a mixed solution A, drop by drop in the mixed solution A Add acetic acid aqueous solution to obtain mixed solution B; wherein the organic solvent is a mixed solvent of ethanol and mesitylene; wherein the concentration of mesitylaldehyde in mixed solution A is 0.12mol / L, 5,5'-diamino-2,2 The concentration of '-bipyridine is 0.180mol / L, the volume ratio of ethanol and mesitylene in the organic solvent is 2:1, the concentration of acetic acid aqueous solution is 5.0mol / L, and the volume ratio of acetic acid aqueous solution and organic solvent is 1:5.5 ;

[0039] (2) Freeze the mixed solution B in the high borosilicate glass tube in step (1) sequentially with liquid nitrogen and vacuumize it with a mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com