Preparation method of cigarette butt tar extract with aroma characteristic and application of cigarette butt tar extract in cigarettes

A technology of extracts and cigarettes, applied in the field of tobacco technology, to achieve the effects of low cost, solving the lack of smoke, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of cigarette tar extract

[0029] A method for preparing a cigarette butt tar extract with aroma-inducing properties comprises the following steps:

[0030] (1) Pretreatment of cigarette butts: tear off the outer wrapping paper of cigarette butts, and cut the tow into small sections less than 1 cm in length;

[0031] (2) Add 100 g of the pretreated cigarette butts into 1 L of absolute ethanol, extract in a reflux water bath at 60° C. for 4 h, and centrifuge at 1000 r / min for 2 min to obtain an extract;

[0032] (3) Distill the extract under reduced pressure with a water pump to remove the organic solvent, then connect it to an oil pump vacuum system, adjust the pressure to 0.5mmH, heat slowly, and collect fractions below 200°C;

[0033] (4) The collected fractions were extracted 3 times with chloroform, the extracts were combined, then concentrated and desolvated on a rotary evaporator, the temperature was controlled at 45 ° C, the pressure was 2...

Embodiment 2

[0052] Example 2 Aroma-inducing properties of cigarette tar extract

[0053] The heat-not-burn cigarette sample A (HnB sample A) was prepared by adding the tar extract prepared in Example 1 to the condensation auxiliary material of the heat-not-burn cigarette at an addition ratio of 3% by weight of the heat-not-burn cigarette.

[0054] The tar extract prepared in Example 1 was added to the filter auxiliary material of the heat-not-burn cigarette at an addition rate of 2% by weight of the heat-not-burn cigarette to prepare the heat-not-burn cigarette sample B (HnB sample B).

[0055]Heat-not-burn cigarette sample C (HnB sample C) was prepared by adding the tar extract prepared in Example 1 to reconstituted shredded tobacco of heat-not-burn cigarettes at an addition ratio of 4% by weight of heat-not-burn cigarettes.

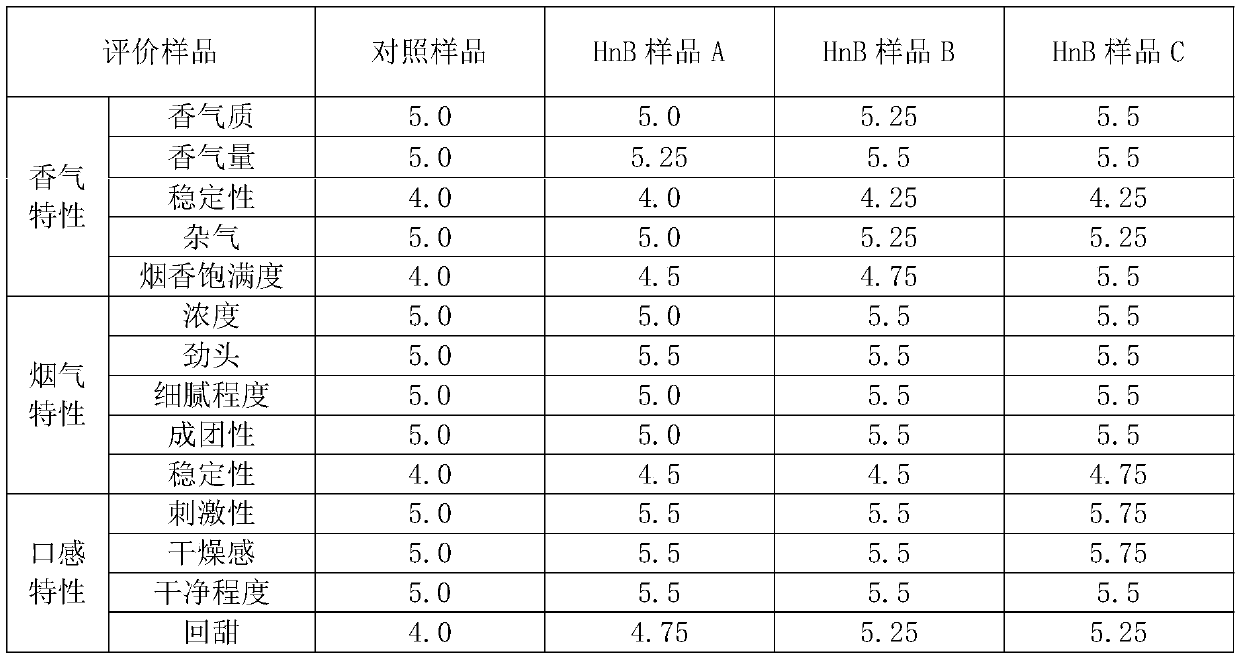

[0056] After the cigarette samples made by the above scheme and the cigarettes without tar extract were balanced for 24 hours in a constant temperature and humid...

Embodiment 3

[0060] Example 3 Selection of preparation method conditions

[0061] 1. Selection of organic solvents

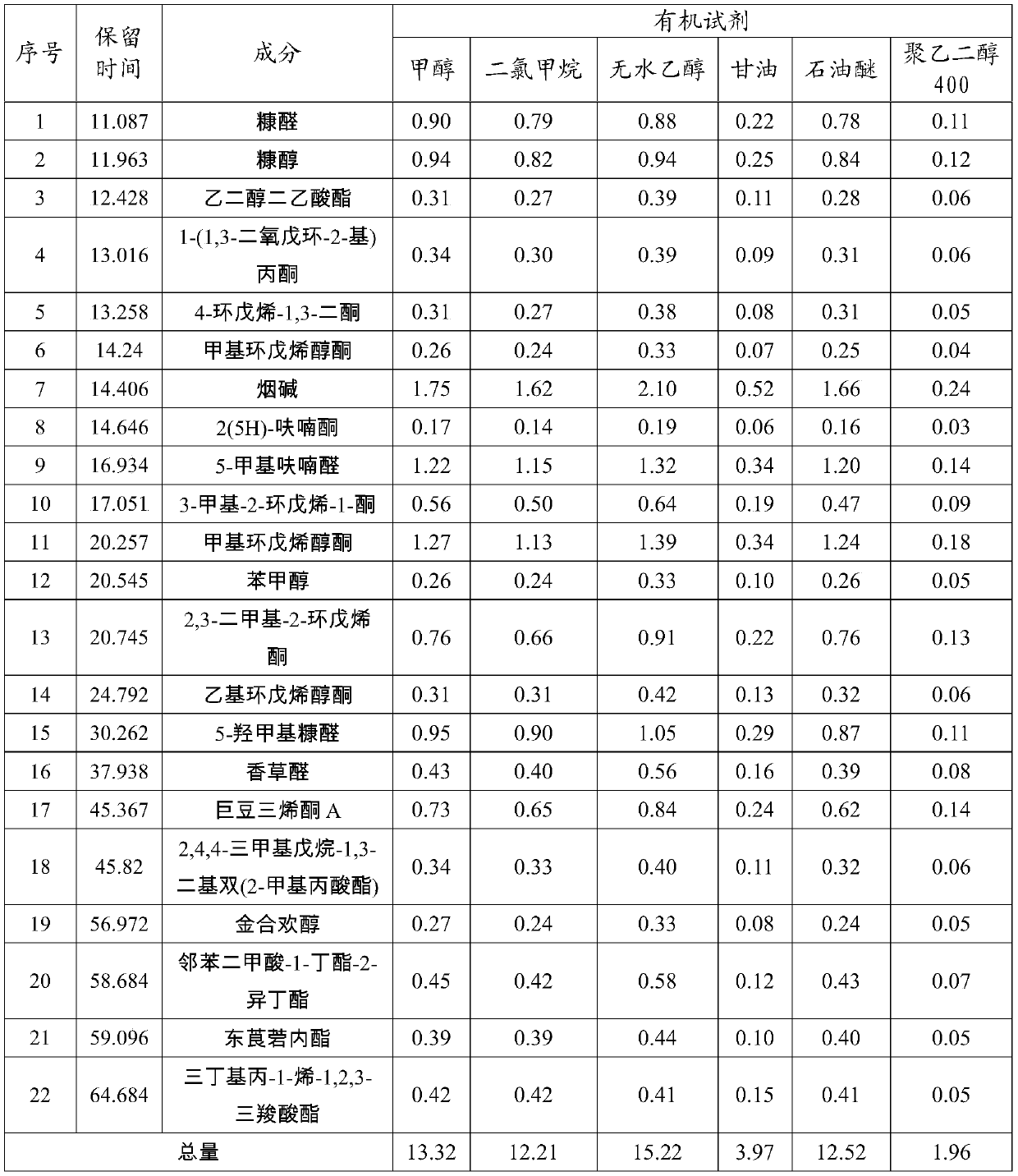

[0062] Use methanol, dichloromethane, absolute ethanol, glycerin, petroleum ether, polyethylene glycol 400 to extract the pretreated cigarette butts, the ratio of solid to liquid is 1:10 (g / mL), the extraction time is 2 hours, and the water bath The temperature was 60°C, and the extraction was performed once. The influence of different solvents on the extraction effect (the content of the extracted components per g of cigarette butt) was compared and analyzed. The test results are shown in Table 2. It can be seen from Table 2 that the extraction effect is the best when using absolute ethanol.

[0063] Extraction effect (mg / g) of different organic solvents of table 2

[0064]

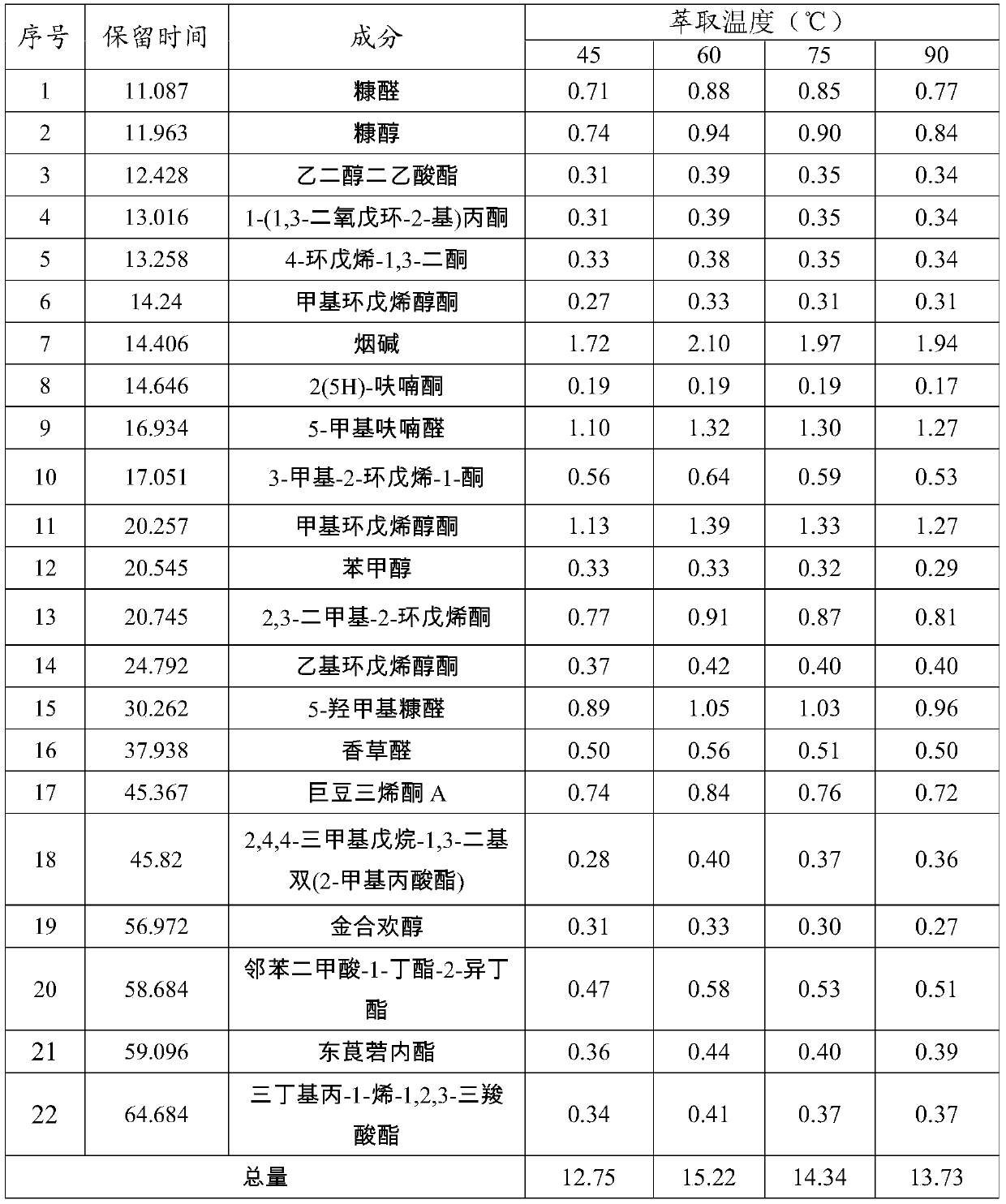

[0065] 2. Selection of extraction temperature

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com