Selective electroless electrochemical atomic layer deposition in aqueous solution without external voltage bias

An atomic layer deposition, electrochemical technology, applied in liquid chemical plating, gaseous chemical plating, coating and other directions, can solve the problem of lack of atomic thickness control in chemical deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

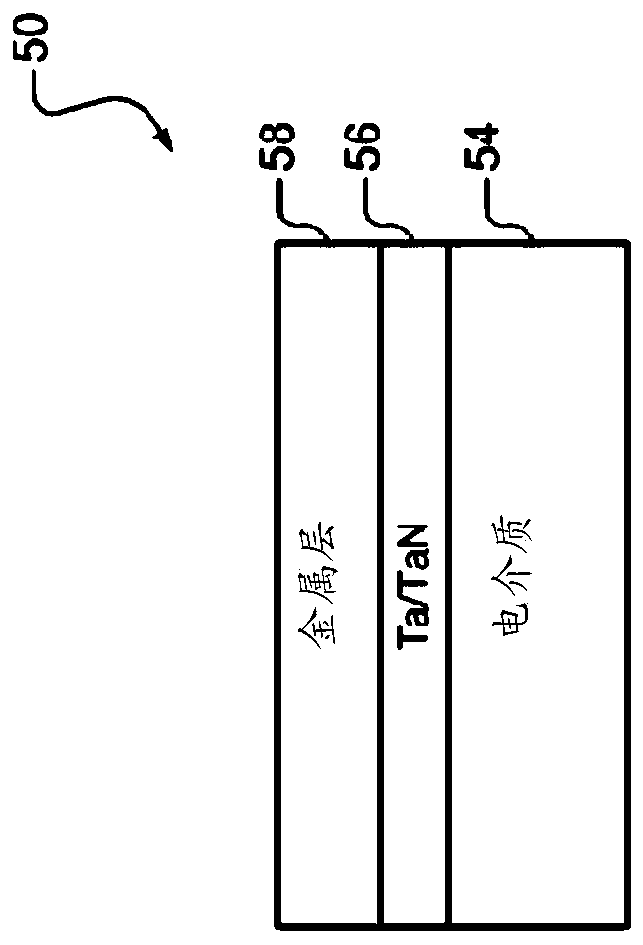

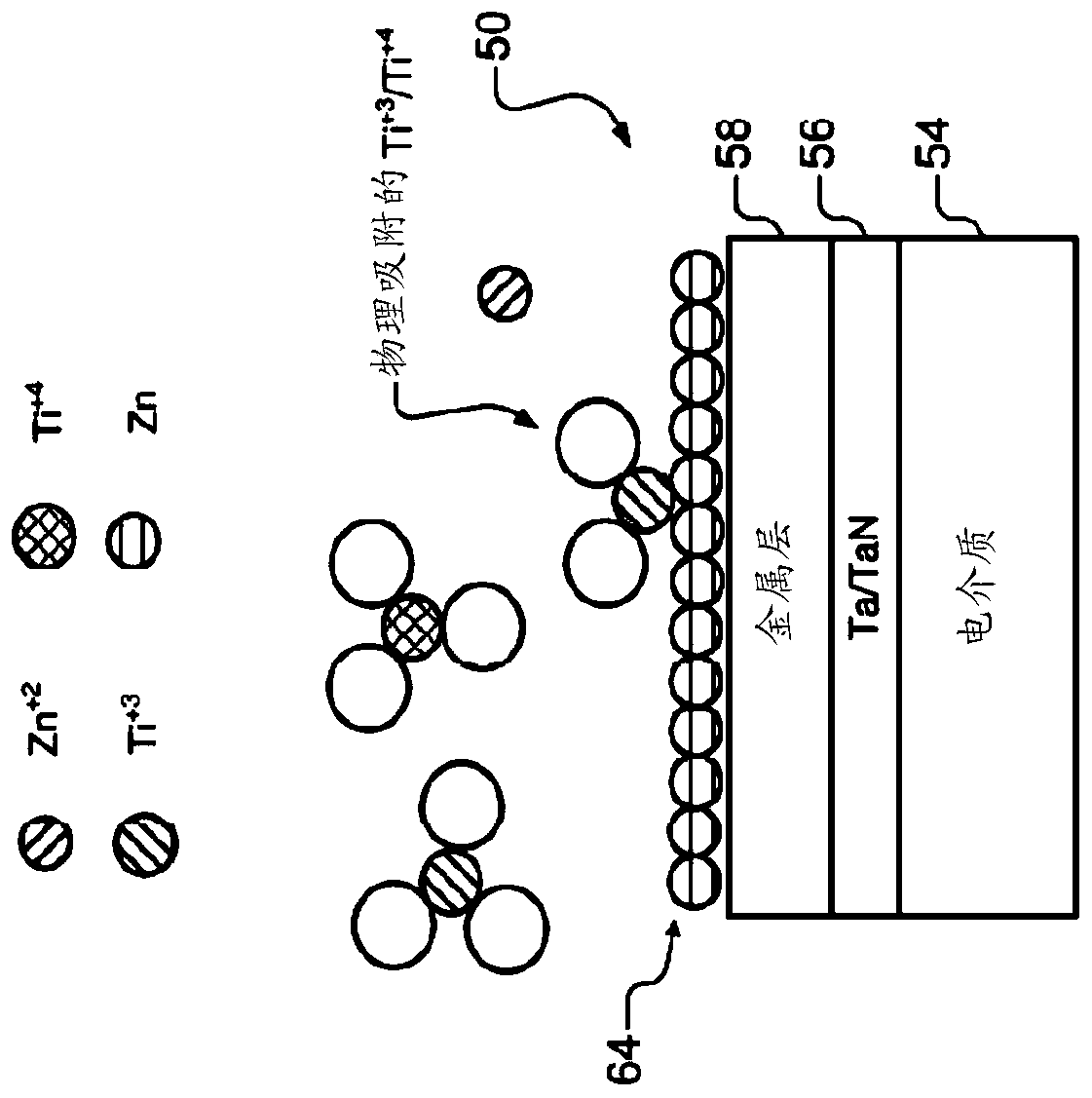

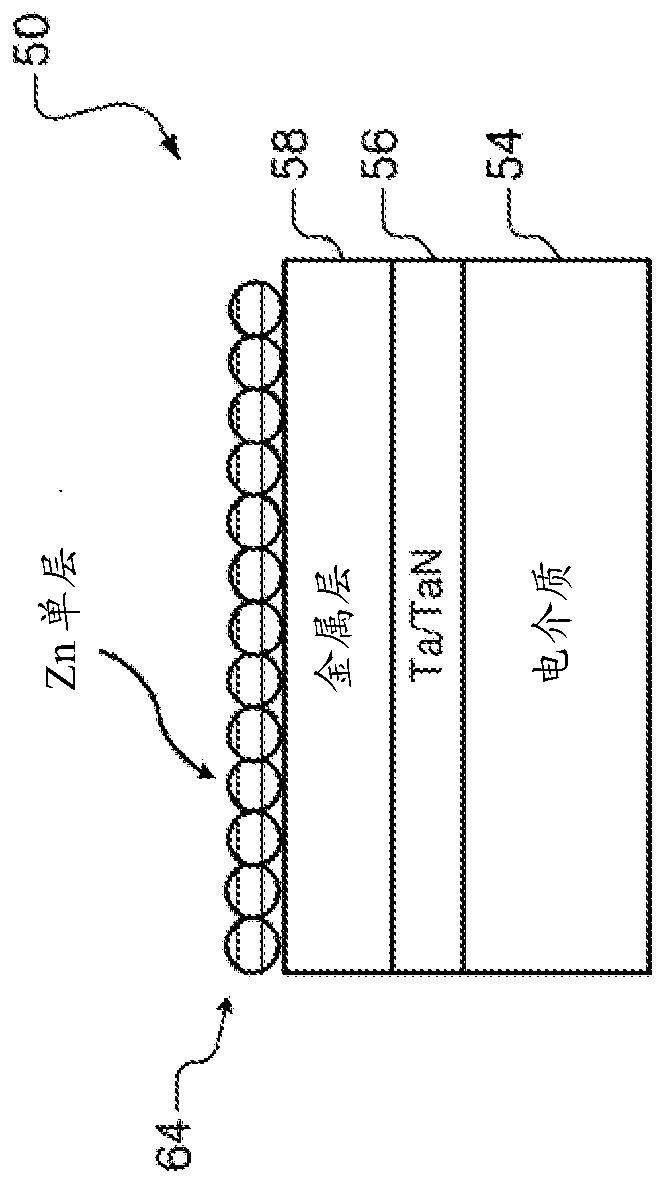

[0035] The method according to the present disclosure performs the desired electroless e-ALD of a metal monolayer on an underlying metal layer in aqueous solution without providing an external voltage bias. The method includes exposing the substrate to a first precursor solution. The first precursor solution deposits a sacrificial metal monolayer on the metal-containing layer of the substrate.

[0036] In some examples, the first precursor solution includes a metal salt. The metal in the metal salt is less noble than the metal required to replace the sacrificial metal monolayer in subsequent steps. In some examples, the sacrificial metal monolayer includes zinc (Zn), and the desired metal (such as copper (Cu), cobalt (Co), ruthenium (Ru), platinum (Pt), or other metal) is more noble than Zn Metal. Although Zn is disclosed, the sacrificial metal monolayer may comprise any metal that is less noble than the desired metal. In some examples, the first precursor solution is an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com