A kind of modified hard carbon negative electrode material and preparation method thereof

A negative electrode material and hard carbon technology, which is applied in the field of modified hard carbon negative electrode materials and its preparation, can solve the problems of low first effect, insignificant improvement of first effect, and low first effect of coated hard carbon materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

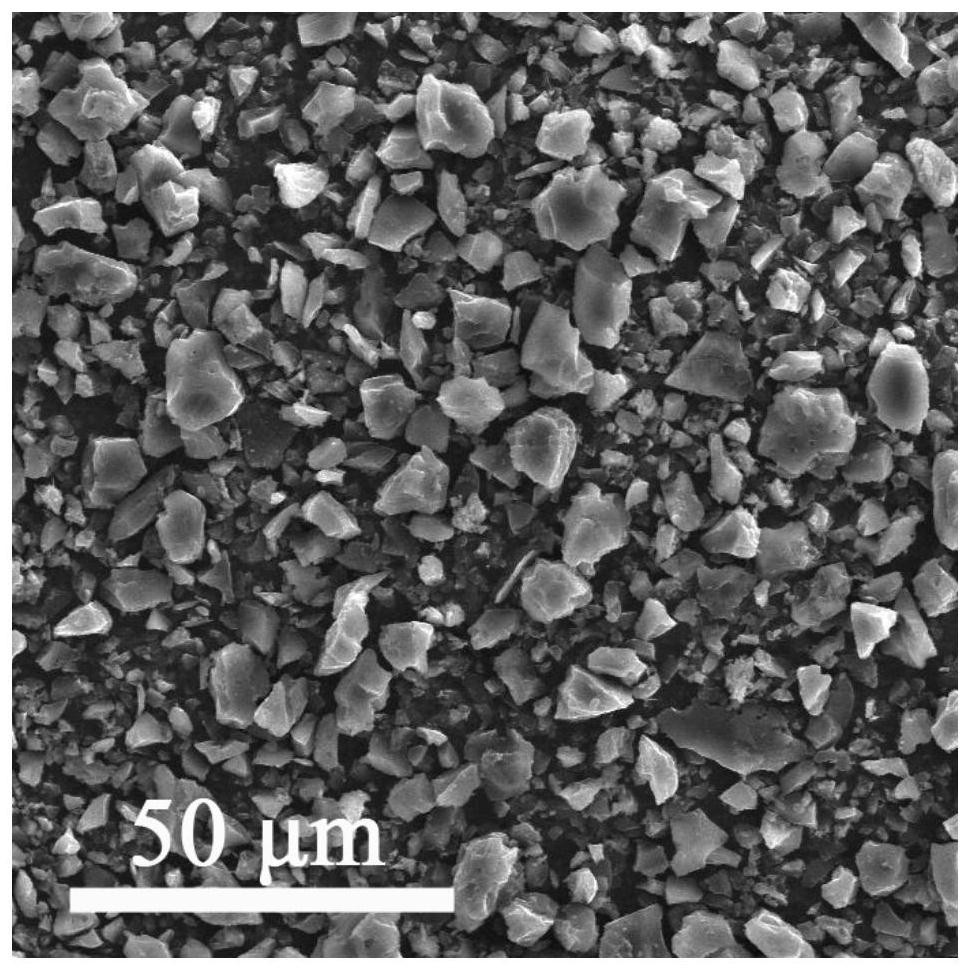

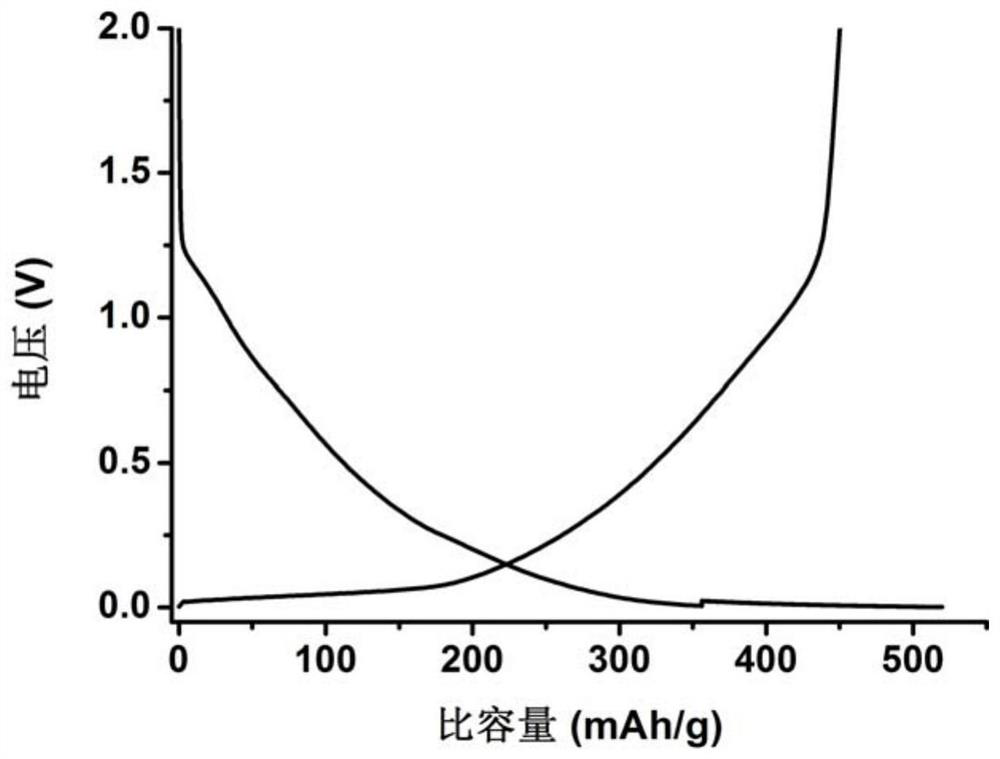

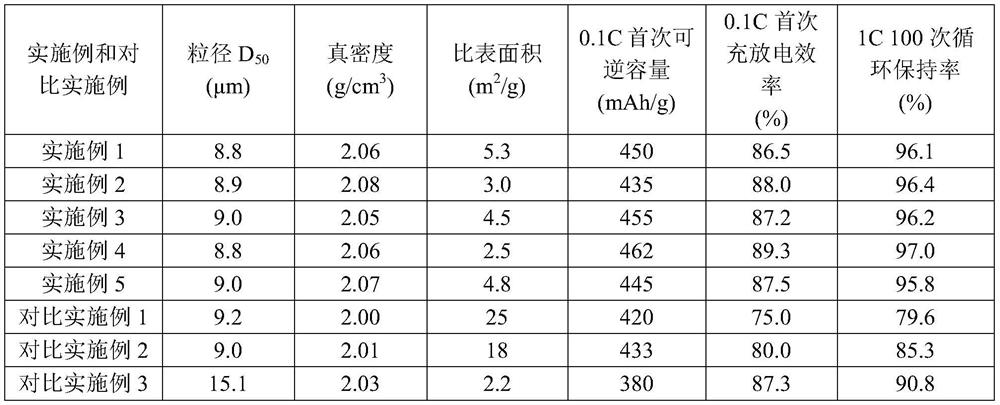

[0022] Add phenol to deionized water and stir until dissolved, add dropwise commercially available ammonia water with 25% ammonia content to adjust the pH to 10, and then add formaldehyde solution with a mass fraction of 37% according to the molar ratio of 1:1 (phenol: formaldehyde) , and stirred and mixed at a speed of 200rpm for 0.5 hours, heated to 50°C for 4 hours of polycondensation reaction to obtain a phenolic resin gel, then transferred to a closed reactor and further aged at 80°C for 8 hours; then put it into a vacuum oven Vacuum dry at 100°C for 10 hours to remove the solvent to obtain phenolic resin, and use a high-speed pulverizer to crush through a 60-mesh standard sieve to obtain phenolic resin powder. Under the protection of nitrogen, the obtained resin powder is heated at 5°C / min to 600°C for pre-carbonization 2 hour, after being down to room temperature, process and adjust the particle diameter (D50) to about 9 μm with airflow pulverization to obtain a hard car...

Embodiment 2

[0024] Add phenol to deionized water and stir until dissolved, add dropwise commercially available ammonia water with 25% ammonia content to adjust the pH to 10, and then add formaldehyde solution with a mass fraction of 37% according to the molar ratio of 1:1 (phenol: formaldehyde) , and stirred and mixed at a speed of 200rpm for 0.5 hours, heated to 50°C for 4 hours of polycondensation reaction to obtain a phenolic resin gel, then transferred to a closed reactor and further aged at 80°C for 8 hours; then put it into a vacuum oven Vacuum dry at 100°C for 10 hours to remove the solvent to obtain phenolic resin, and use a high-speed pulverizer to crush through a 60-mesh standard sieve to obtain phenolic resin powder. Under the protection of nitrogen, the obtained resin powder is heated at 5°C / min to 600°C for pre-carbonization 2 hour, after being down to room temperature, process with jet milling and adjust the particle diameter (D50) to about 9 μm to obtain a hard carbon precur...

Embodiment 3

[0026] Add phenol into deionized water and stir until dissolved, add dropwise commercially available ammonia water with 25% ammonia content to adjust the pH to 10, and then add formaldehyde solution with a mass fraction of 37% according to the molar ratio of 1:2 (phenol: formaldehyde) , and stirred and mixed at a speed of 200rpm for 0.5 hours, heated to 50°C for 4 hours of polycondensation reaction to obtain a phenolic resin gel, then transferred to a closed reactor and further aged at 80°C for 8 hours; then put it into a vacuum oven Vacuum dry at 100°C for 10 hours to remove the solvent to obtain phenolic resin, and use a high-speed pulverizer to crush through a 60-mesh standard sieve to obtain phenolic resin powder. Under the protection of nitrogen, the obtained resin powder is heated at 5°C / min to 600°C for pre-carbonization 2 hour, after being down to room temperature, process and adjust the particle diameter (D50) to about 9 μm with airflow pulverization to obtain a hard c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com