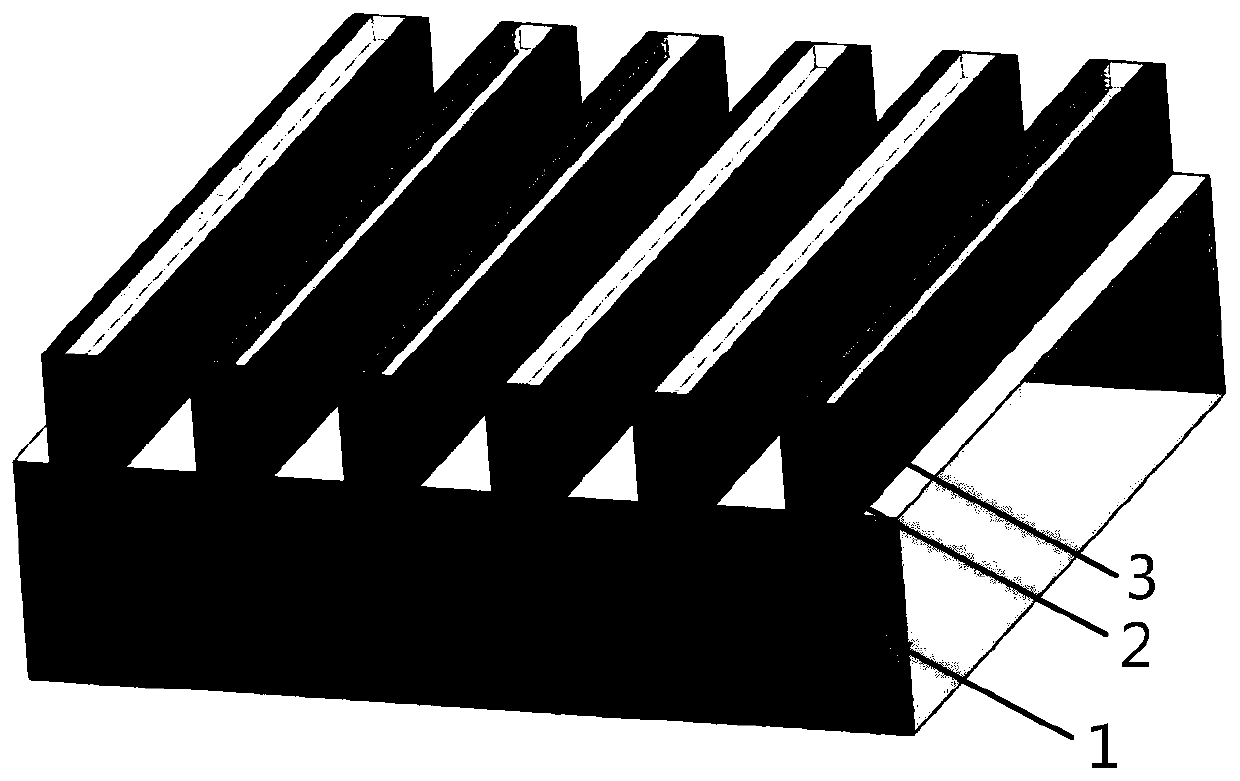

Metal wire grating polarizer with deep ultraviolet composite structure

A composite structure and metal wire grid technology, which is applied in polarizing components, instruments, optics, etc., can solve the problems of not considering the stability of polarization performance, high polarization transmittance and extinction ratio, and strict grating period restrictions, so as to meet the requirements of Performance requirements, reduction of processing difficulty and cost, effect of long cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

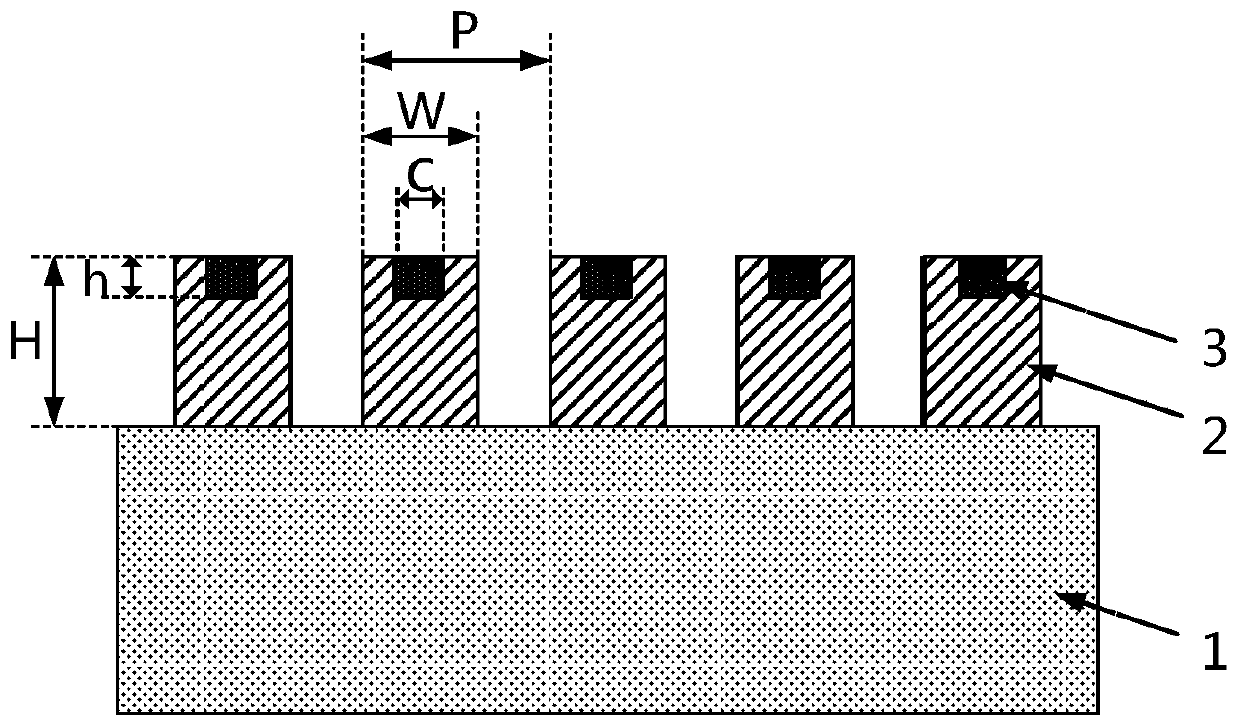

[0027] The metal aluminum grating and the magnesium fluoride dielectric filling structure have the same period P of 134nm, aluminum grid duty ratio W / P of 0.67, and aspect ratio H / W of 2.5. The width of the rectangular magnesium fluoride dielectric filled structure is 32 nm, and the depth is 15 nm.

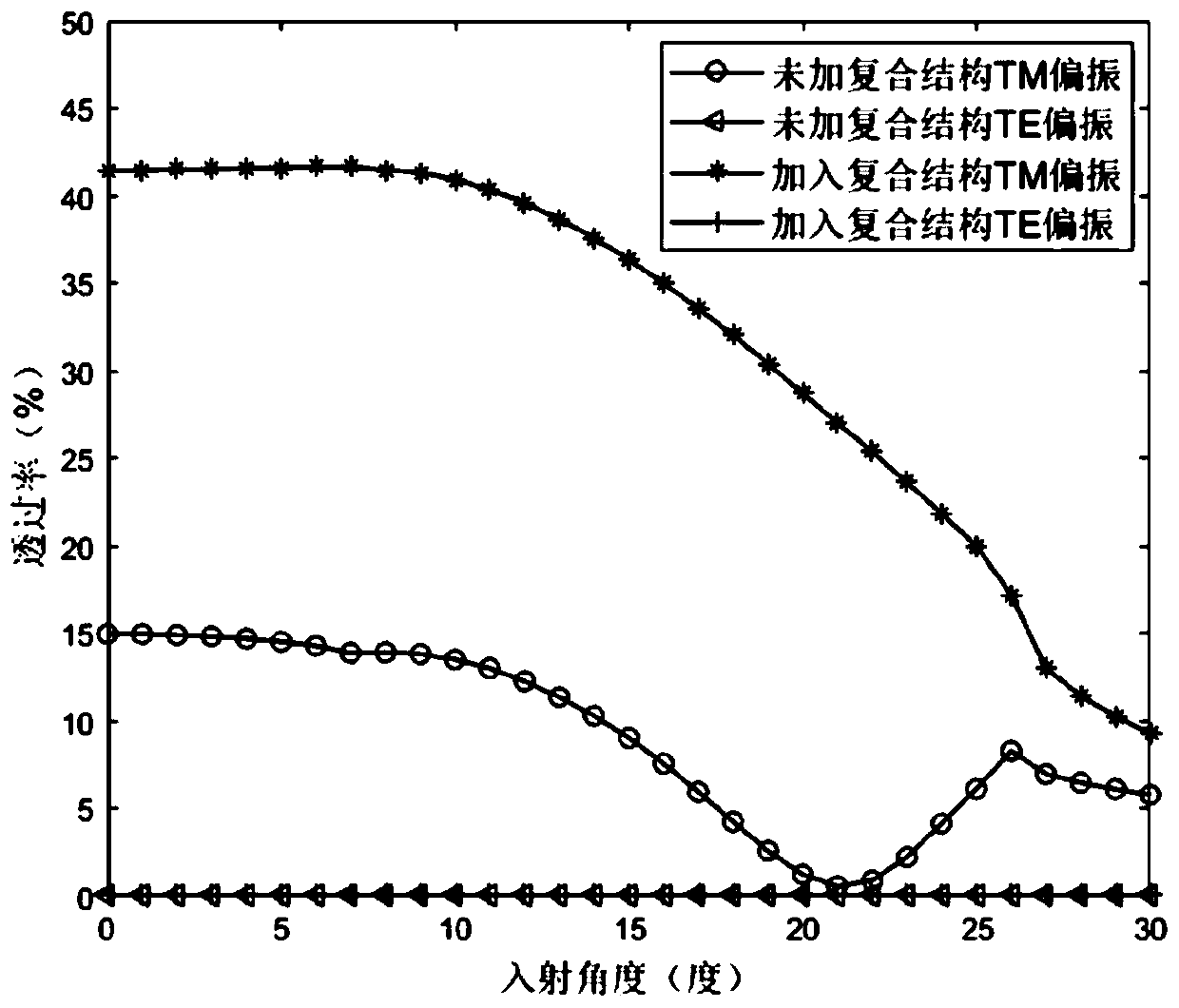

[0028] see image 3 , image 3 It is a graph of the transmittance of TM polarized light and TE polarized light of embodiment 1 with the incident angle. Among them, the o line type represents the TM polarized light transmittance without a composite structure wire grid polarizer, the Δ line type represents the TE polarized light transmittance without a composite structure wire grid polarizer, and the * line type represents without a composite structure wire grid Polarizer TM polarized light transmittance, + line means TE polarized light transmittance without compound structure wire grid polarizer. Depend on image 3 It can be seen that at normal incidence, the polarized light tr...

Embodiment 2

[0031] The metal aluminum grating and the silicon dioxide dielectric filling structure have the same period P of 176nm, aluminum grid duty ratio W / P of 0.74, and aspect ratio H / W of 3. The width of the rectangular silicon dioxide dielectric filled structure is 84nm, and the depth is 60nm.

[0032] see Figure 5 , Figure 5 It is a graph of the transmittance of TM polarized light and TE polarized light of embodiment 2 with the incident angle. Among them, the o line type represents the TM polarized light transmittance without a composite structure wire grid polarizer, the Δ line type represents the TE polarized light transmittance without a composite structure wire grid polarizer, and the * line type represents without a composite structure wire grid Polarizer TM polarized light transmittance, + line means TE polarized light transmittance without compound structure wire grid polarizer. Depend on Figure 5It can be seen that at normal incidence, the transmittance of the polar...

Embodiment 3

[0035] The metal aluminum grating and the silicon dioxide dielectric filling structure have the same period P of 200nm, aluminum grid duty ratio W / P of 0.76, and aspect ratio H / W of 1.52. The width of the rectangular silicon dioxide dielectric filling structure is 80 nm, and the depth is 30 nm.

[0036] see Figure 7 , Figure 7 It is a graph of the transmittance of TM polarized light and TE polarized light of embodiment 3 with the incident angle. Among them, the o line type represents the TM polarized light transmittance without a composite structure wire grid polarizer, the Δ line type represents the TE polarized light transmittance without a composite structure wire grid polarizer, and the * line type represents without a composite structure wire grid Polarizer TM polarized light transmittance, + line means TE polarized light transmittance without compound structure wire grid polarizer. Depend on Figure 7 It can be seen that at normal incidence, the polarized light tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com