Double-stage air replenishing compressor, freezing and cold storage refrigerating system and control method

A refrigeration system and control method technology, which is applied to compressors, irreversible cycle compressors, refrigerators, etc., can solve problems such as abnormal noise, performance attenuation, and small pressure difference between suction and exhaust, so as to ensure performance reliability and reduce Operating frequency, the effect of eliminating collision noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

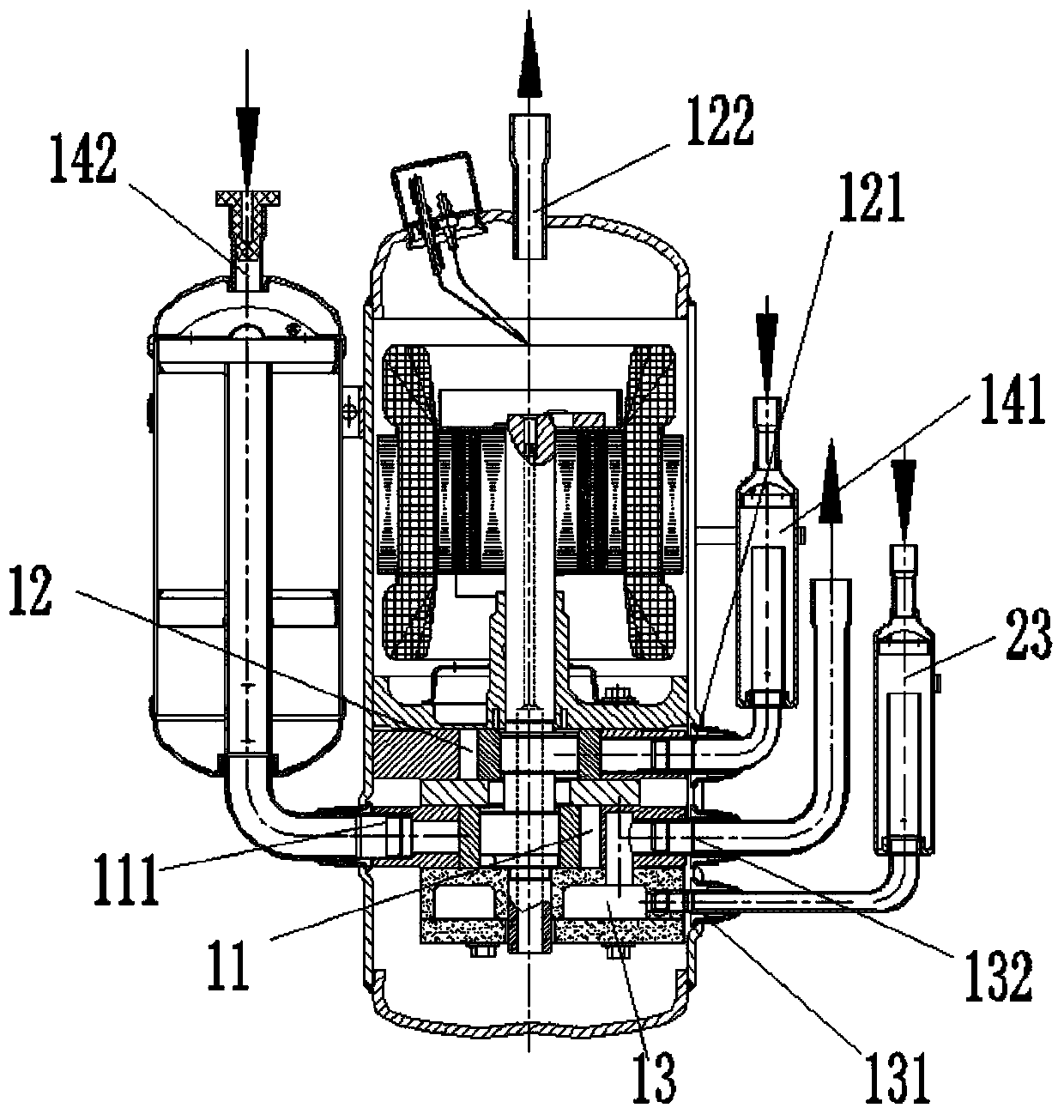

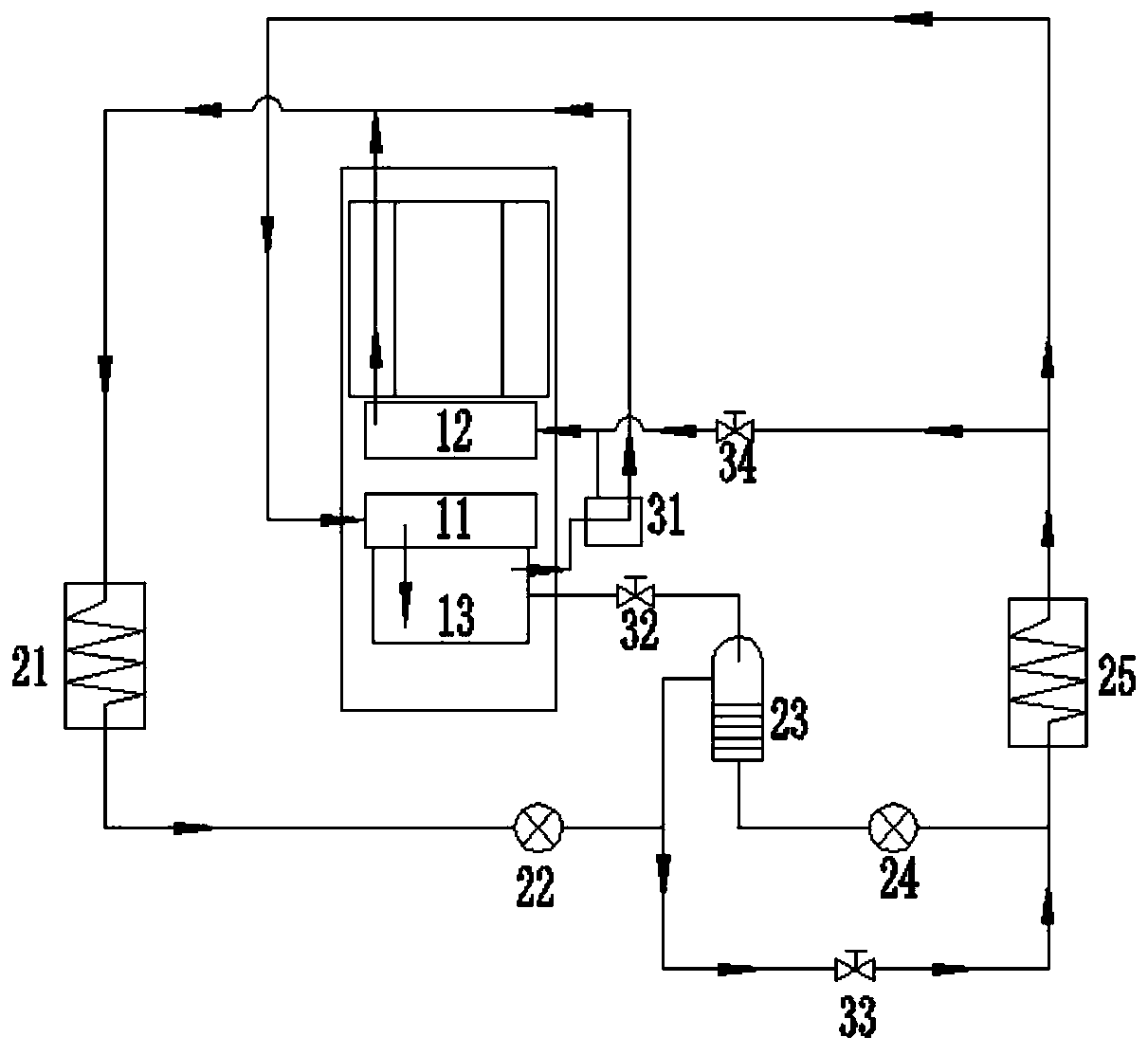

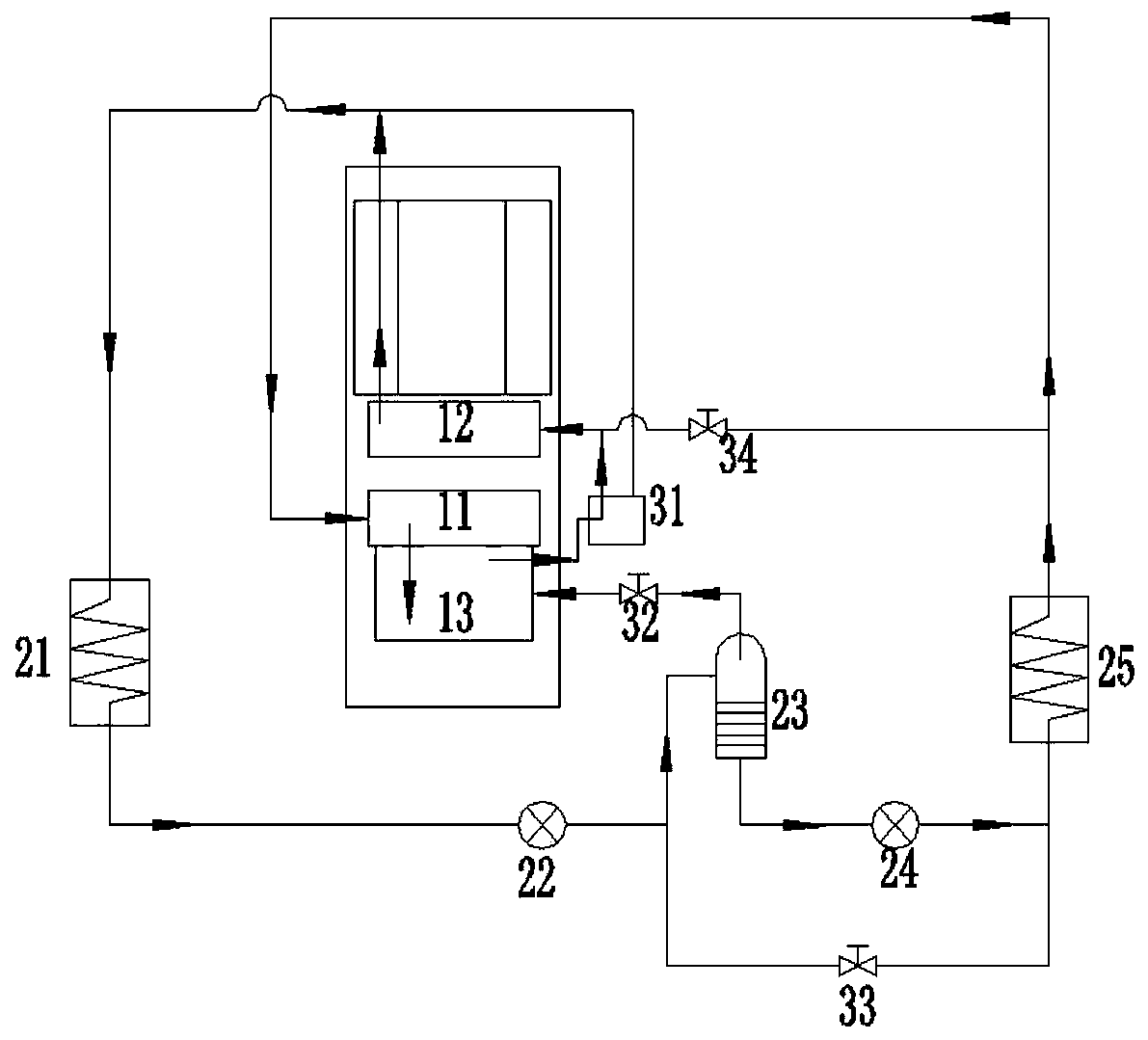

[0026] see in conjunction Figure 1 to Figure 3 As shown, according to the embodiment of the present invention, a two-stage air supplementary compressor is provided, especially a two-stage air supplementary rotary compressor, which includes a low-pressure stage compression chamber 11, a high-pressure stage compression chamber 12, an intermediate air supplementary chamber 13. The low-pressure stage compression chamber 11 has a low-pressure stage suction port 111 and a low-pressure stage exhaust port, and the high-pressure stage compression chamber 12 has a high-pressure stage suction port 121 and a high-pressure stage exhaust port 122. The chamber 13 has an air supply port 131 and a mixed exhaust port 132, and the low-pressure stage compression chamber 11 is connected through the middle air supply chamber 13 through the low-pressure stage exhaust port. It can be understood that the low-pressure stage compression chamber 11 and the high-pressure stage compression chamber 12 real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com