Supercritical carbon dioxide power generation system based on absorption heat pump waste heat recovery

An absorption heat pump and carbon dioxide technology, which is applied in heat recovery systems, machines/engines, energy-saving heating/cooling, etc., can solve the problem of insufficient utilization of waste heat from gas turbine exhaust, so as to improve cycle thermal efficiency, improve power generation efficiency, and reduce smoke exhaust. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

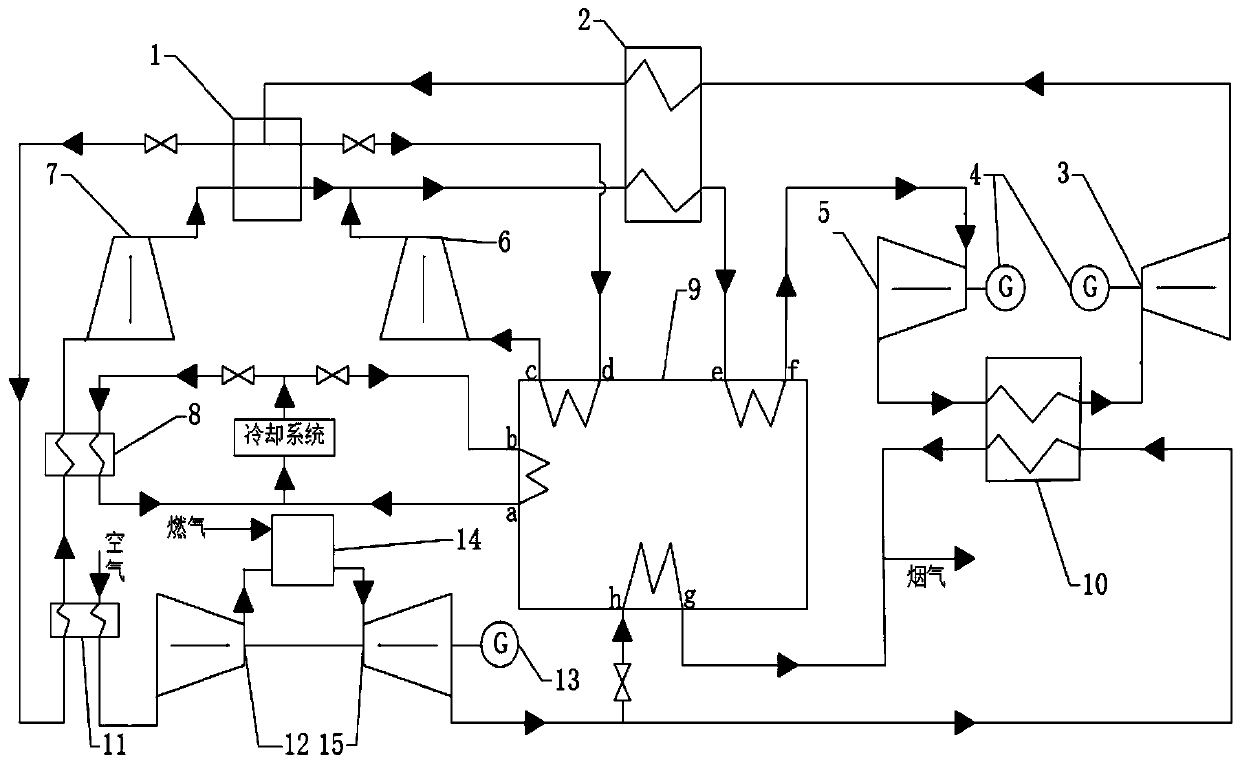

[0023] A supercritical carbon dioxide power generation system based on absorption heat pump waste heat recovery of the present invention, its preferred specific implementation is:

[0024] include:

[0025] Supercritical carbon dioxide Brayton cycle system, absorption heat pump cycle system, traditional gas-fired Brayton cycle system and cooling system;

[0026] The supercritical carbon dioxide Brayton cycle system includes: a main compressor, a recompressor, a high-temperature regenerator, a low-temperature regenerator, a high-pressure turbine, a low-pressure turbine, a generator, a flue gas regenerator, and a condenser; The compressor and the turbine are designed with different shafts, and the flue gas regenerator is arranged between the high-pressure turbine and the low-pressure turbine;

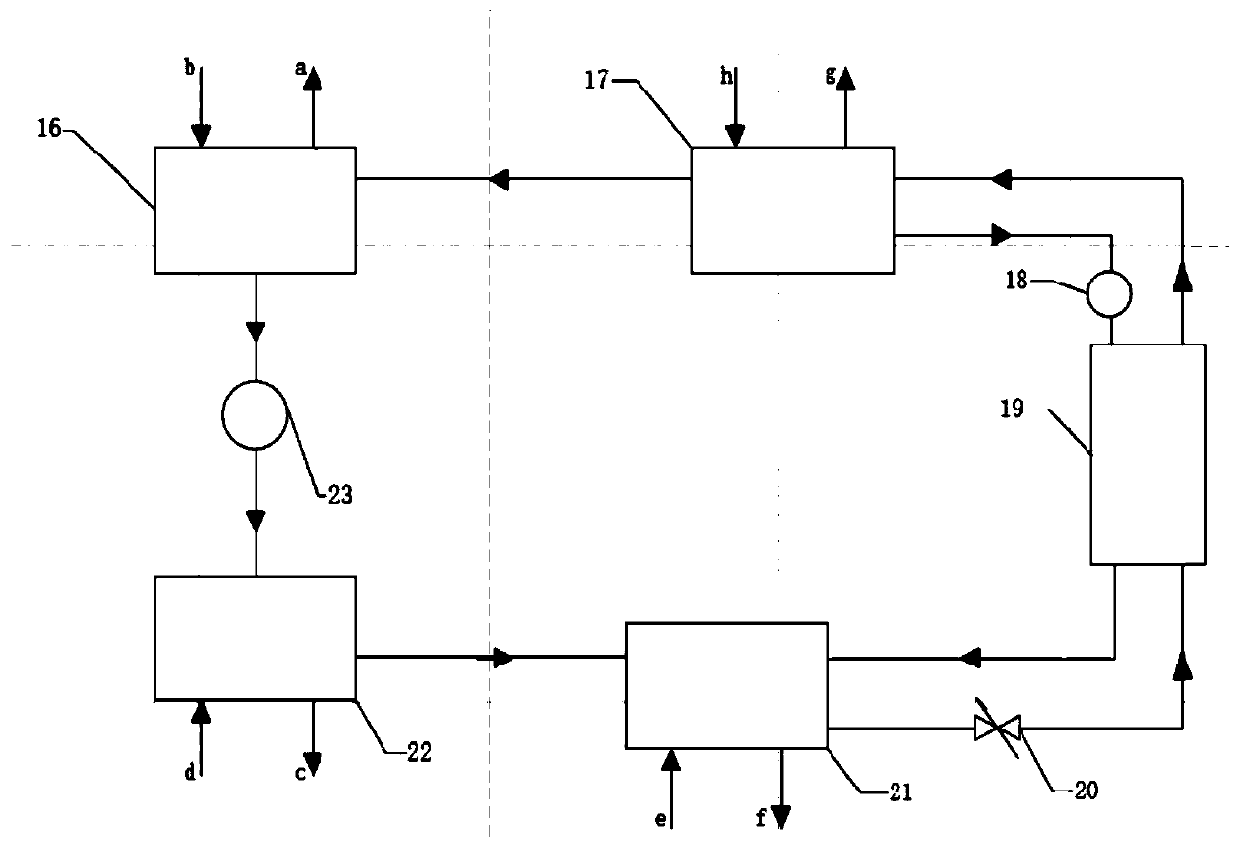

[0027] The absorption heat pump cycle system uses a lithium bromide absorption heat pump, including a second condenser, a generator, a solution booster pump, a solution exchanger, a thro...

specific Embodiment

[0047] Such as figure 1 , figure 2 As shown, including supercritical carbon dioxide Brayton cycle system, absorption heat pump cycle system, traditional gas type Brayton cycle system and cooling system;

[0048] The supercritical carbon dioxide Brayton cycle system described therein includes: main compressor 7, recompressor 6, high temperature regenerator 2, low temperature regenerator 1, high pressure turbine 5, low pressure turbine 3, generator 4, flue gas A gas regenerator 10 and a condenser 8; the inlet of the main compressor is connected to the condenser 8, and the outlet is connected to the low-temperature regenerator 1; the inlet of the re-compressor 6 is connected to the evaporator of the absorption heat pump 9, and the outlet is connected to the high-temperature regenerator 2; The high temperature regenerator 2 is connected to the inlet of the absorber 21 of the absorption heat pump, the outlet of the absorber 21 of the absorption heat pump 9 is connected to the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com