A circular section multilayer sheet type cfrp cable system

A technology of multi-layer sheets and circular cross-sections, which is applied in the direction of buildings, building reinforcements, building components, etc., can solve the problems of poor wind-induced vibration resistance of cables and difficult anchoring of cables, so as to save costs and reduce anchorage. With size, the effect of improving self-damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

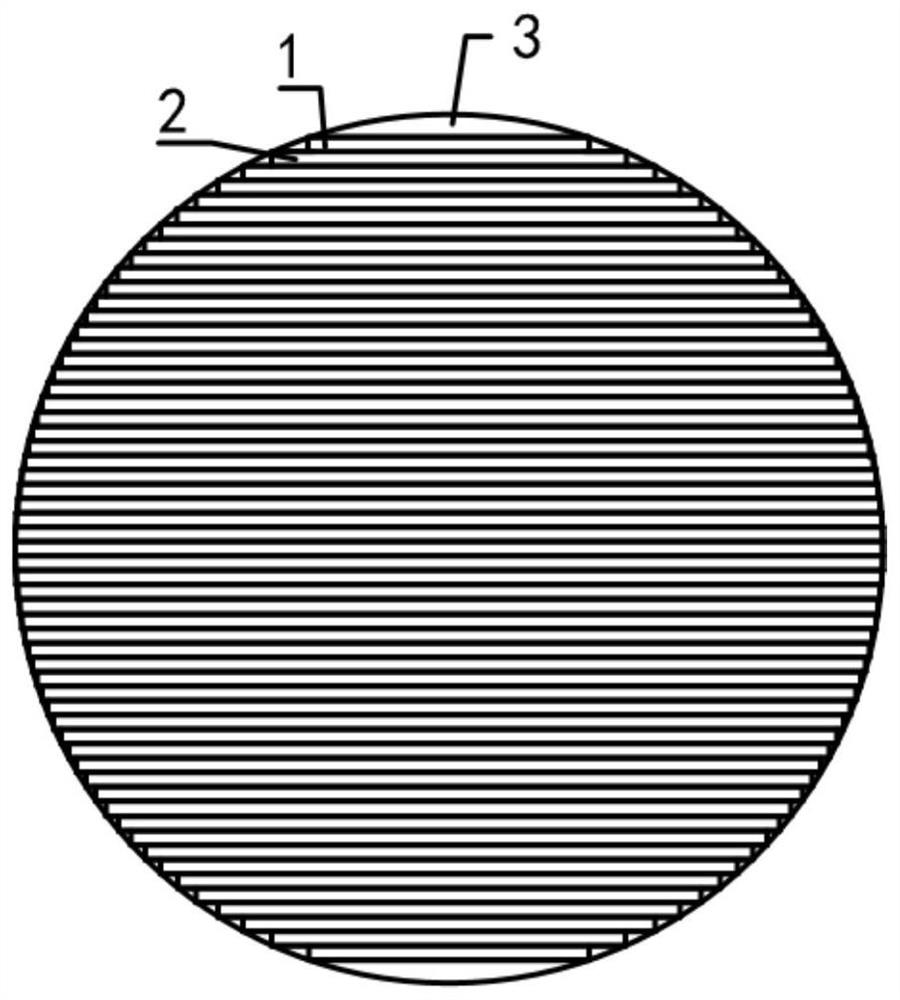

Image

Examples

example 1

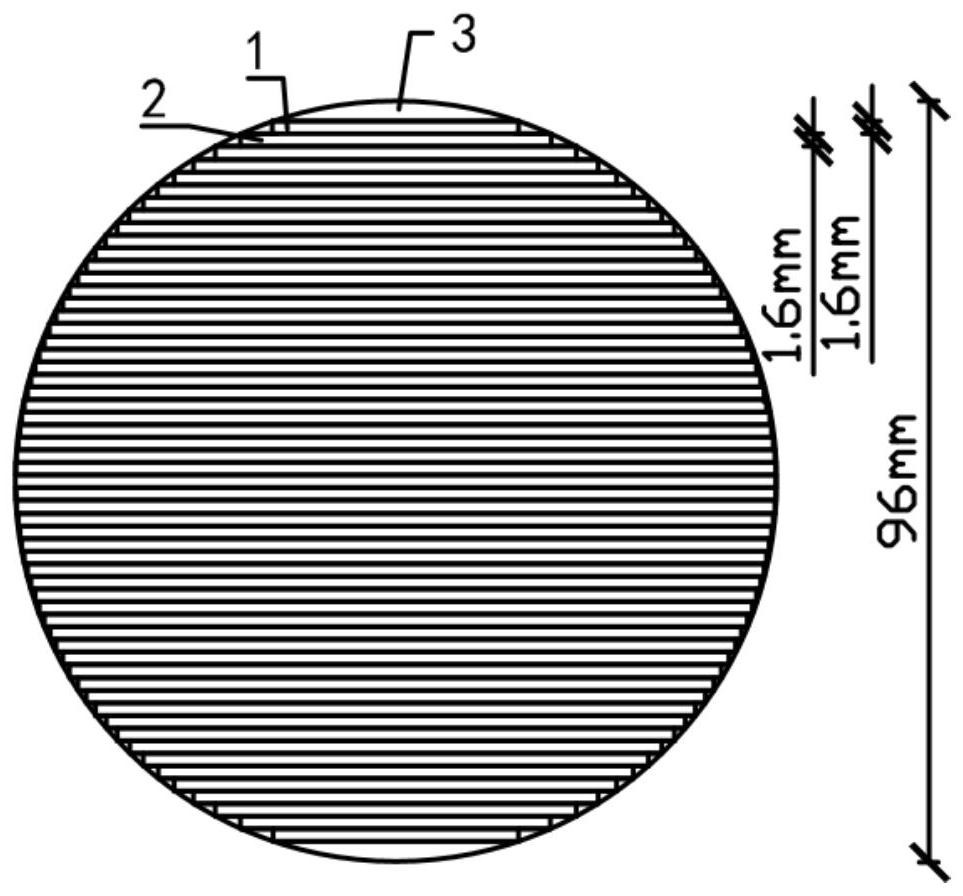

[0031] According to the method, the outer diameter of the polyethylene pipe sheath is 100mm (inner diameter 96mm, thickness 2mm), and the thickness of the sheet is 1.6mm;

[0032] The thickness of each layer of CFRP sheet is 1.6mm, and the thickness of each layer of sheet-type foam is 1.6mm;

[0033] The width of the middle layer of CFRP sheet

[0034] up or down from the middle

[0035] Layer 1 width is:

[0036] Layer 2 width is:

[0037] Calculate layer by layer to:

[0038] Layer 13 width is:

[0039] Layer 14 width is:

[0040] Sheet type foam up or down from the middle layer

[0041] Layer 1 width is:

[0042] Layer 2 width is:

[0043] Calculate layer by layer to:

[0044] Layer 13 width is:

[0045] Layer 14 width is:

[0046] According to the calculation given above, this example 1 can determine the number of layers of CFRP sheets: 2×14+1=29 layers, as attached Figure 4 shown;

[0047] The number of sheet-type foam layers is: 2×14=28 la...

example 2

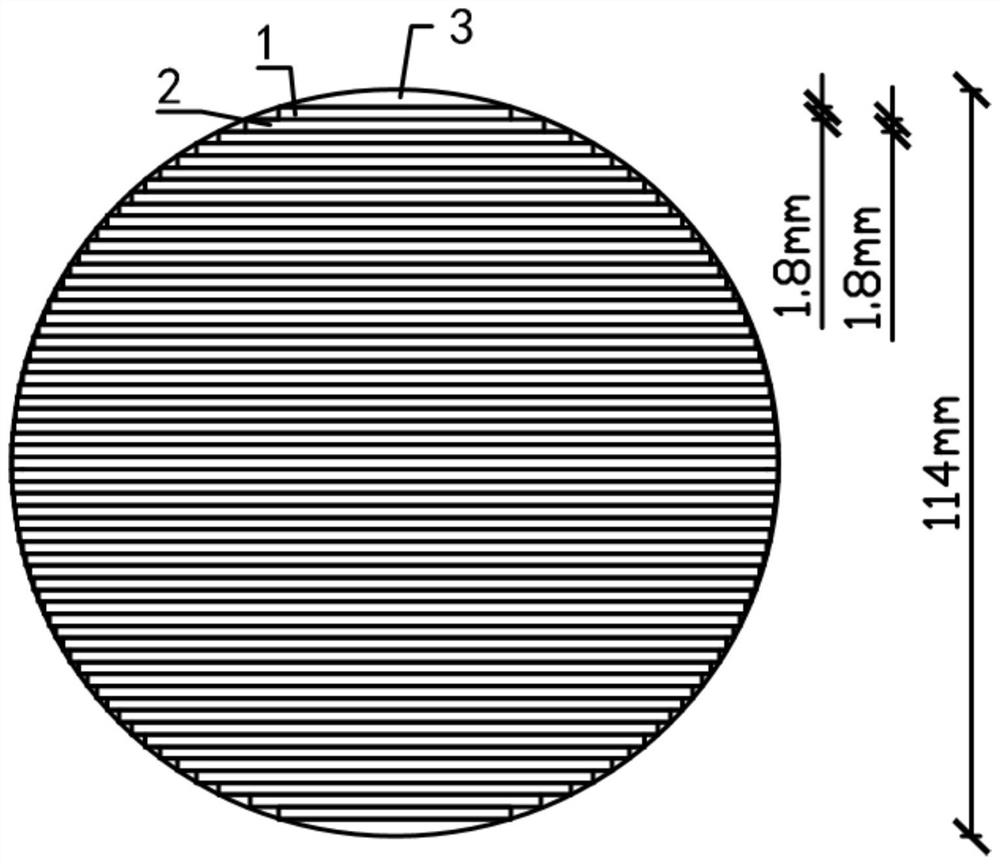

[0055] Compared with example one, this example two adopts said method to determine the circular section and the same implementation steps; the difference is that the outer diameter of the polyethylene pipe sheath is 120mm (inner diameter 114mm, thickness 3mm), and the sheet thickness 1.8mm;

[0056] The thickness of each layer of CFRP sheet is 1.8mm, and the thickness of each layer of sheet-type foam is 1.8mm;

[0057] The width of the middle layer of CFRP sheet

[0058] up or down from the middle

[0059] Layer 1 width is:

[0060] Layer 2 width is:

[0061] Calculate layer by layer to:

[0062] Layer 14 width is:

[0063] Layer 15 width is:

[0064] Sheet type foam up or down from the middle layer

[0065] Layer 1 width is:

[0066] Layer 2 width is:

[0067] Calculate layer by layer to:

[0068] Layer 14 width is:

[0069] Layer 15 width is:

[0070] According to the calculation given above, the number of layers of CFRP sheet can be determined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com