360-degree rotating chute used for open caisson concrete pouring

A concrete and chute technology, applied in construction, water conservancy projects, artificial islands, etc., can solve the problems of long pouring construction period, high pouring cost, limited construction area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

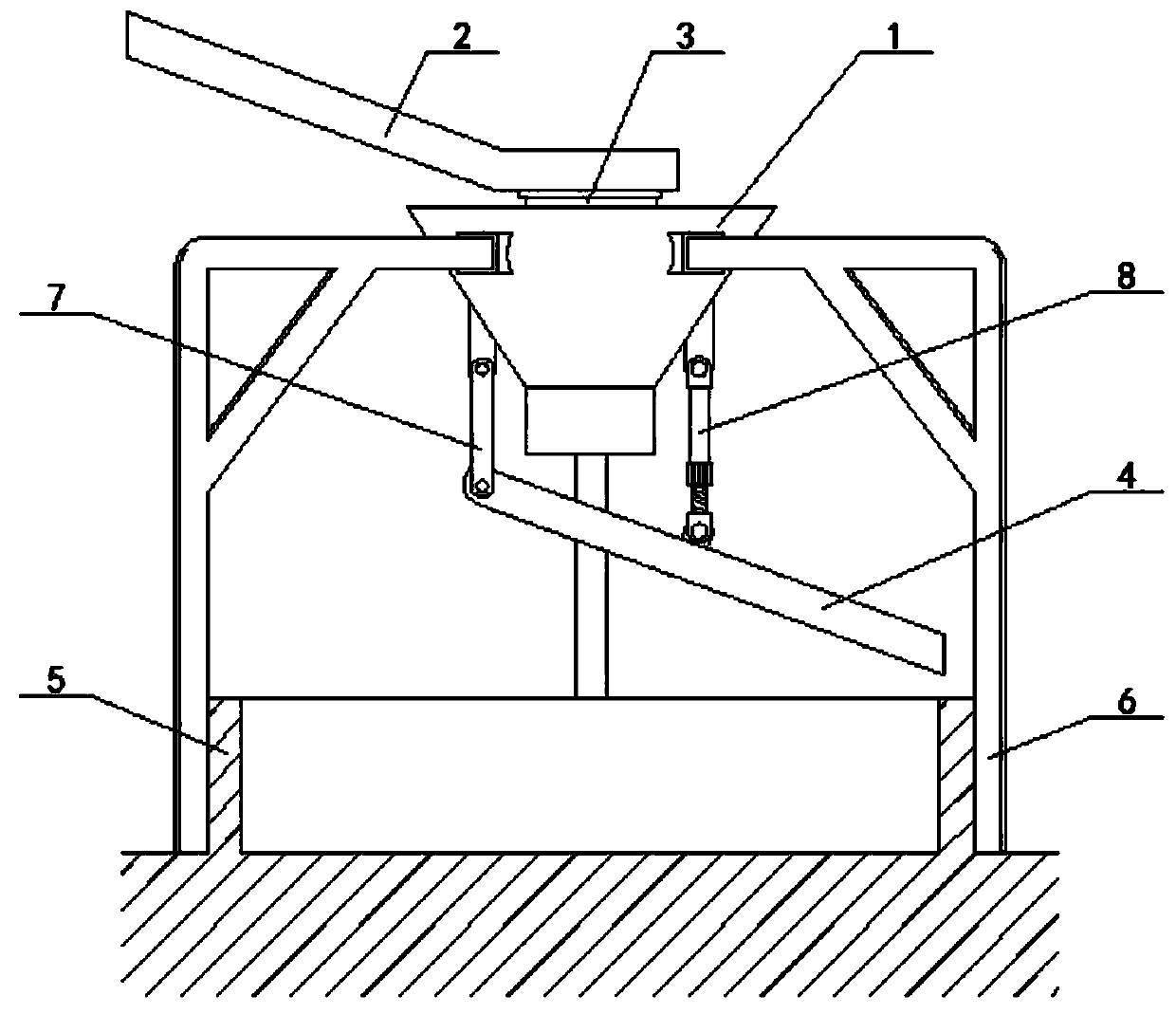

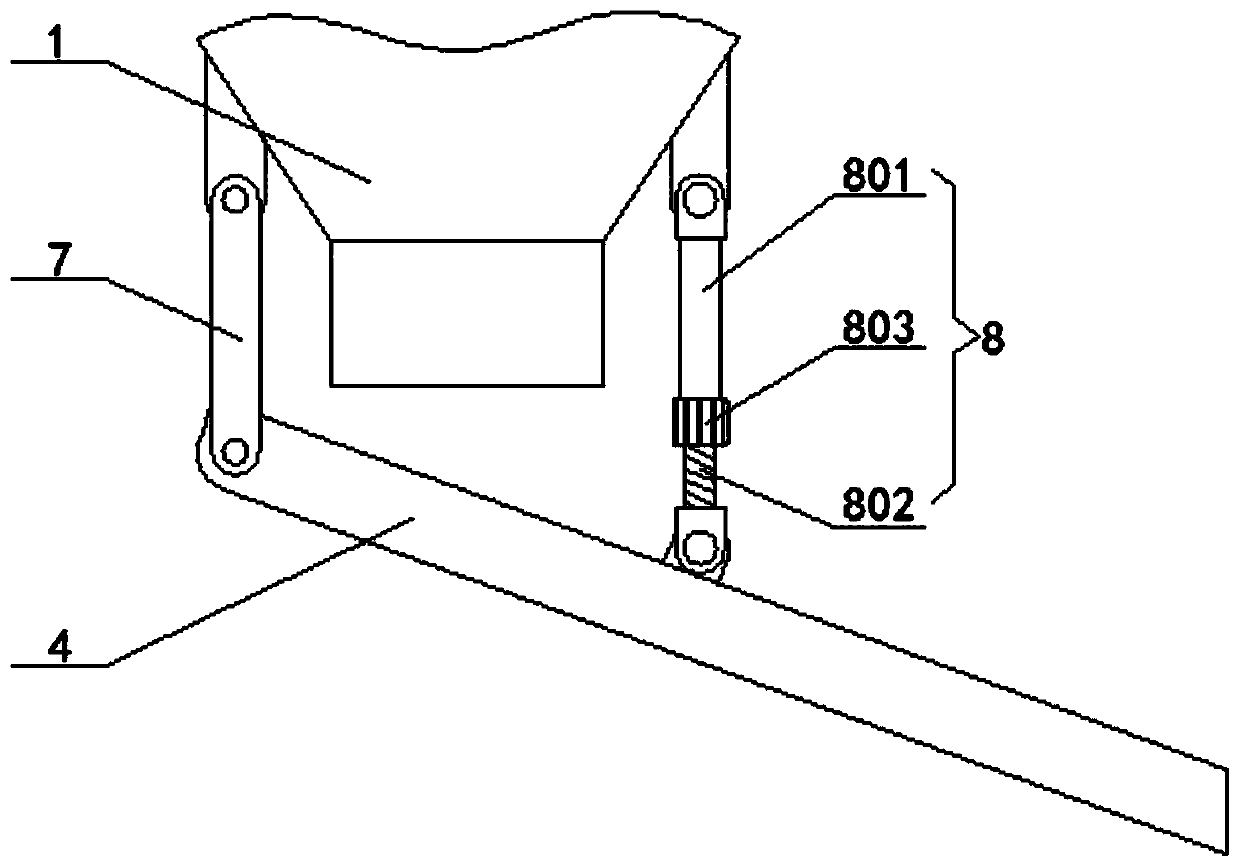

[0026] see Figure 1-3 , the present invention provides a technical solution: a 360-degree rotating chute for caisson concrete pouring, including a hopper 1, an upper chute 2, a lower chute 4 and a well wall 5 to be poured, and a hopper is arranged on the top of the well wall 5 to be poured 1. A rotatable upper chute 2 is installed on the top of hopper 1. The bottom of hopper 1 rotates on the left side and is connected with a connecting rod 7. The bottom end of connecting rod 7 rotates and connects to the lower chute 4. The bottom of hopper 1 rotates on the right side. An adjustable telescopic rod 8 is connected, and the bottom end of the adjustable telescopic rod 8 is rotationally connected with the lower chute 4 .

Embodiment 2

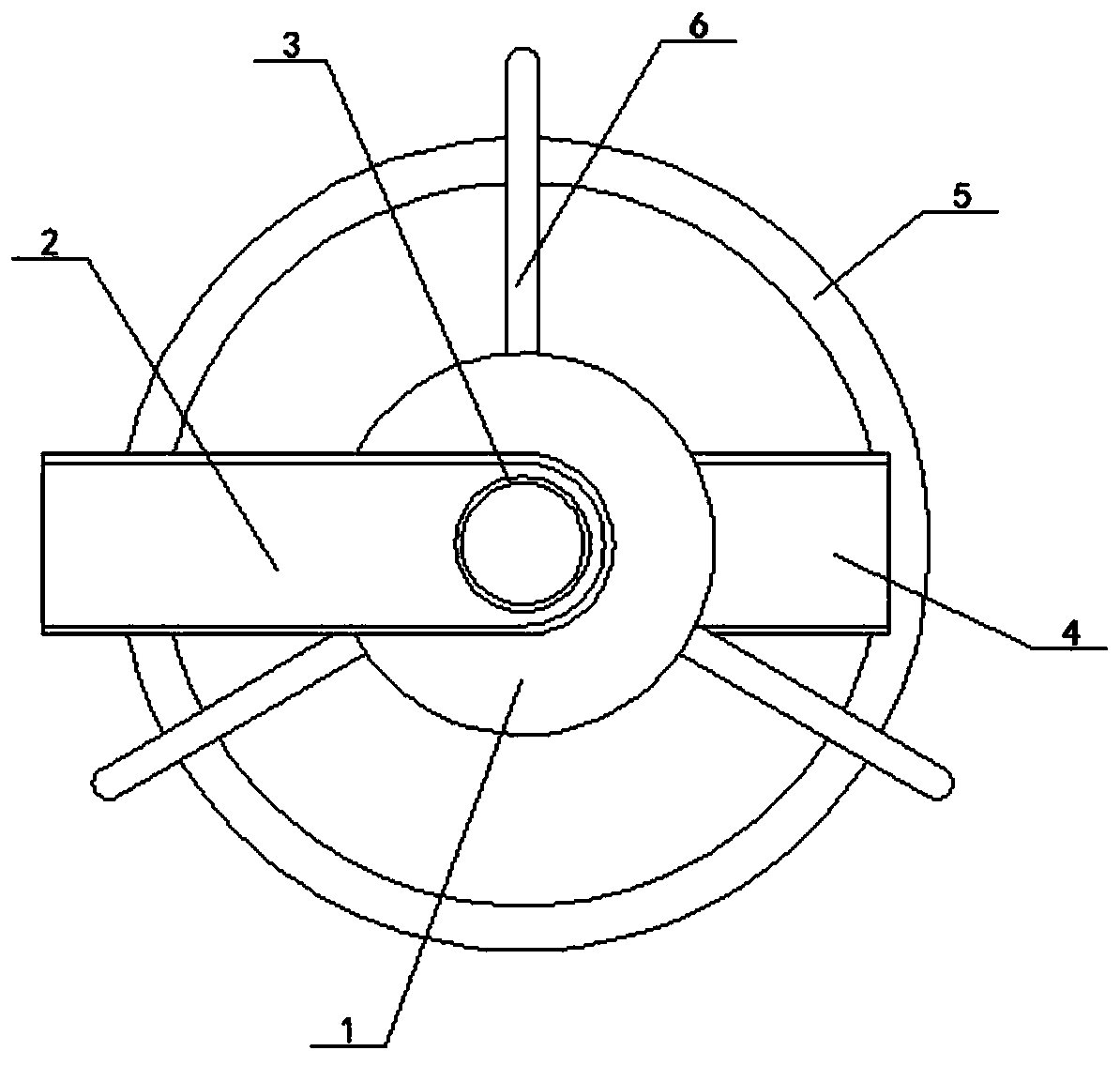

[0028] Specifically, such as figure 1 and figure 2 As shown, the middle part of the upper end surface of the hopper 1 is connected with a vertically distributed feeding pipe 3, and a bearing sleeve is installed between the feeding pipe 3 and the upper chute 2, and the outside of the hopper 1 is equipped with multiple sets of fixed scaffolds distributed in a circular array. 6, and multiple sets of fixed scaffolding 6 are in an inverted L-shaped structure, the upper chute 2 and the lower chute 4 are distributed obliquely, and the setting of the feeding pipe 3 facilitates the flow of concrete from the upper chute 2 into the hopper 1, which is an inverted L-shaped structure The setting of the fixed scaffold 6 facilitates the installation and handling of the bracket of the hopper 1.

Embodiment 3

[0030] Specifically, such as figure 1 and image 3 As shown, the adjustable telescopic rod 8 is composed of an outer tube 801, a screw rod 802 and a screw sleeve 803, the inner side of the bottom end of the outer tube 801 is embedded with a screw rod 802, and the bottom end of the outer tube 801 is located at the outer side of the screw rod 802 and is connected with a screw rod. The sleeve 803, the outer tube 801 and the screw 802 form a transition fit. The selection of the transition fit improves the stability of the screw 802 sliding inside the outer tube 801. The setting of the screw sleeve 803 facilitates the sliding adjustment process of the screw 802 inside the outer tube 801.

[0031] Working principle: When in use, according to the pouring requirements of the municipal sewage interception pipe network, select a fixed scaffold 6 of a specified size to install and erect the hopper 1 above the well wall 5 to be poured, according to the diameter of the well wall 5 to be po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com