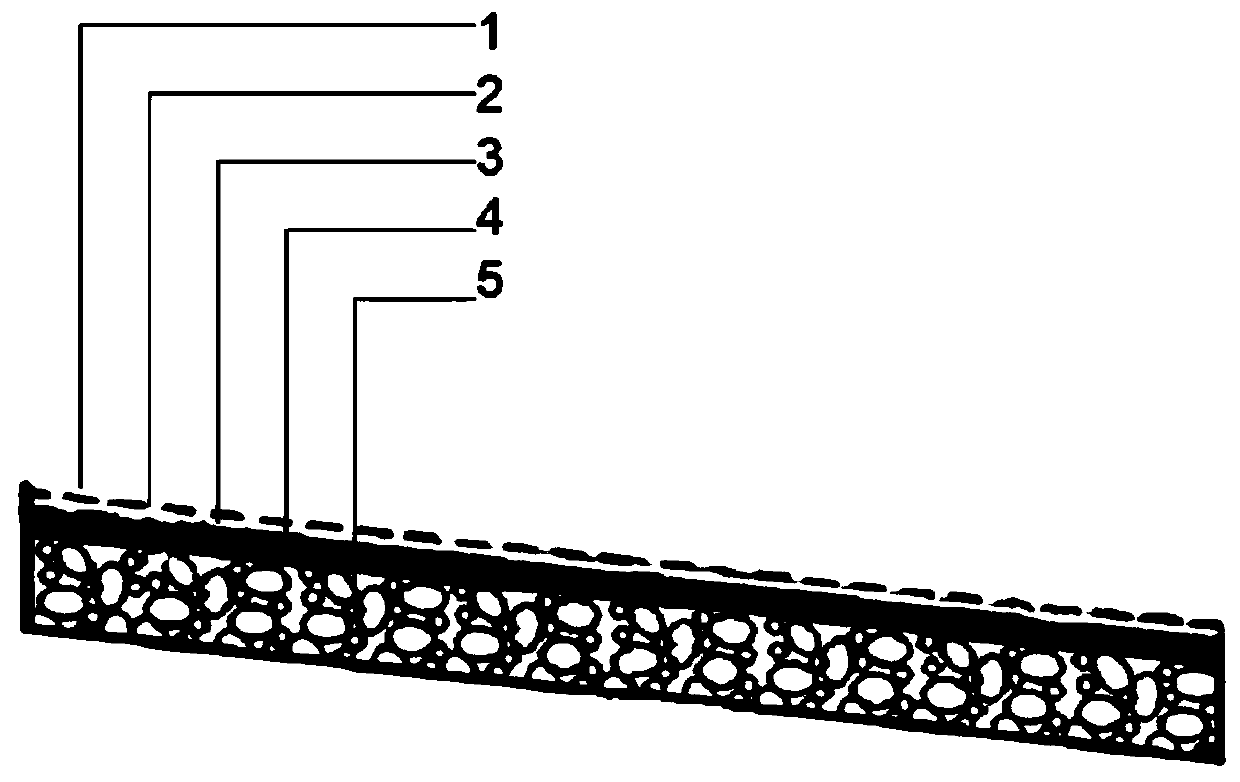

Underground garage anti-skid ramp composite system and construction process

An underground garage and composite system technology, applied in the field of anti-skid ramp composite system and construction technology in underground garages, can solve the problems of car tire damage, driving comfort, poor anti-heavy pressure, long construction period, etc. Short construction period and reduced frictional noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In one embodiment, the preparation method of the topcoat prepared from the raw materials for the sealing layer on the basal surface comprises: adding a thickener to water at room temperature, stirring at a stirring speed of 500-600 rpm after dispersion until the consistency is no longer When increasing, add fungicide and acrylic emulsion, and stir again at a stirring speed of 300-400 rpm for 2 minutes.

[0037] Preferably, the preparation method of the topcoat prepared from the raw materials for the basal sealing layer comprises: at room temperature, adding a thickener to water, stirring at a stirring speed of 550 rpm after dispersion until the consistency no longer increases, Add the bactericide and acrylic emulsion, and stir again at a stirring speed of 350 rpm for 2 minutes.

[0038] The sealing layer of the base surface of the present invention can be well combined with the base surface of the ramp, and form an effective bonding layer, enhance waterproof, anti-acid ...

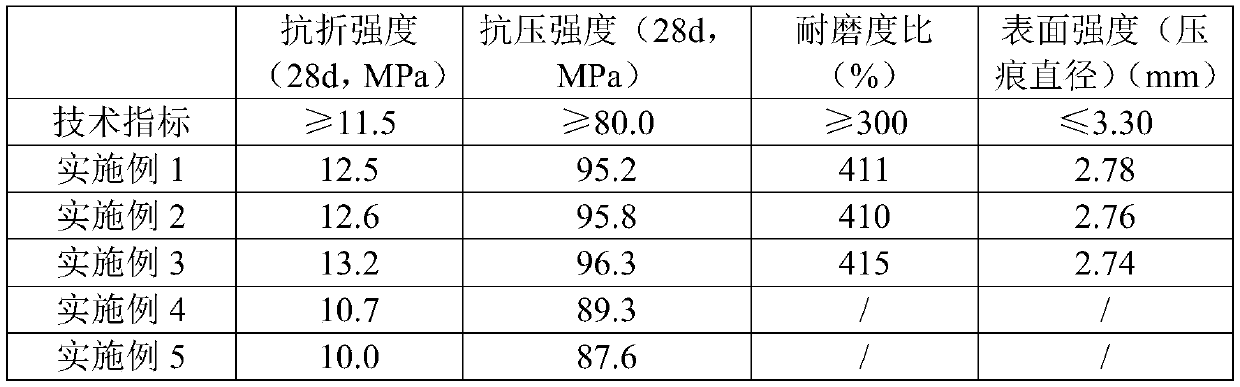

Embodiment 1

[0099] Embodiment 1 of the present invention provides a kind of compound system of anti-skid ramp of underground garage, and it comprises base surface sealing layer, anti-pressure structure layer, antiskid damping layer and self-cleaning protection layer; By weight, described base surface sealing layer The raw materials for preparation include 43 parts of acrylic emulsion, 43 parts of water, 0.8 parts of thickener, and 0.2 parts of bactericide; in parts by weight, the preparation raw materials of the pressure-resistant structural layer include 30 parts of cement, 45 parts of graded sand, 5 parts of nano-silica, 2.5 parts of redispersible latex powder, 0.5 parts of water-retaining agent, 0.5 parts of water-repellent, 1.5 parts of pigment; by weight, the preparation raw materials of the anti-slip damping layer include 25 parts of cement, 62 parts Steel sand, 0.4 parts of silica fume powder, 1.5 parts of redispersible latex powder, 0.5 parts of water-retaining agent, 0.5 parts of ...

Embodiment 2

[0112] Embodiment 2 of the present invention provides a kind of composite system of anti-skid ramp for underground garage, which comprises a base surface sealing layer, a compressive structure layer, an anti-slip damping layer and a self-cleaning protective layer; by weight, the base surface sealing layer The raw materials for preparation include 55 parts of acrylic emulsion, 55 parts of water, 2.5 parts of thickener, and 0.5 part of bactericide; in parts by weight, the raw materials for the preparation of the pressure-resistant structural layer include 45 parts of cement, 60 parts of graded sand, 8 parts of nano-silica, 4.5 parts of redispersible latex powder, 2 parts of water-retaining agent, 3 parts of water-repellent, 5 parts of pigment; by weight, the preparation raw materials of the anti-slip damping layer include 35 parts of cement, 72 parts Steel sand, 0.8 parts of silica fume powder, 2.5 parts of redispersible latex powder, 2 parts of water-retaining agent, 2 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com