Sealing structure in automobile cooling transmission device

A technology of transmission device and sealing structure, which is applied in the field of machinery to achieve the effects of good waterproof performance, convenient manufacturing, assembly and disassembly, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] As shown in Figure 1, main shaft 3 and belt pulley 4 are provided in this automobile cooling transmission device, belt pulley 4 is sleeved on the main shaft 3, and bearing one 5 and bearing two 6 are arranged between belt pulley 4 and main shaft 3.

[0027] The sealing structure in the automobile cooling transmission device includes a sealing cover 2 sleeved on the main shaft 3 and a sealing gasket 1 nested on the outside of the sealing cover 2, which is arranged on the end face of the pulley 4; 4 end caps 9 at the outer ends.

[0028] Wherein the sealing gasket 1 and the pulley 4 are fixedly connected by screws, and the sealing cover 2 is pressed on the inner ring of the bearing one 5 through the shoulder 7 of the main shaft 3 .

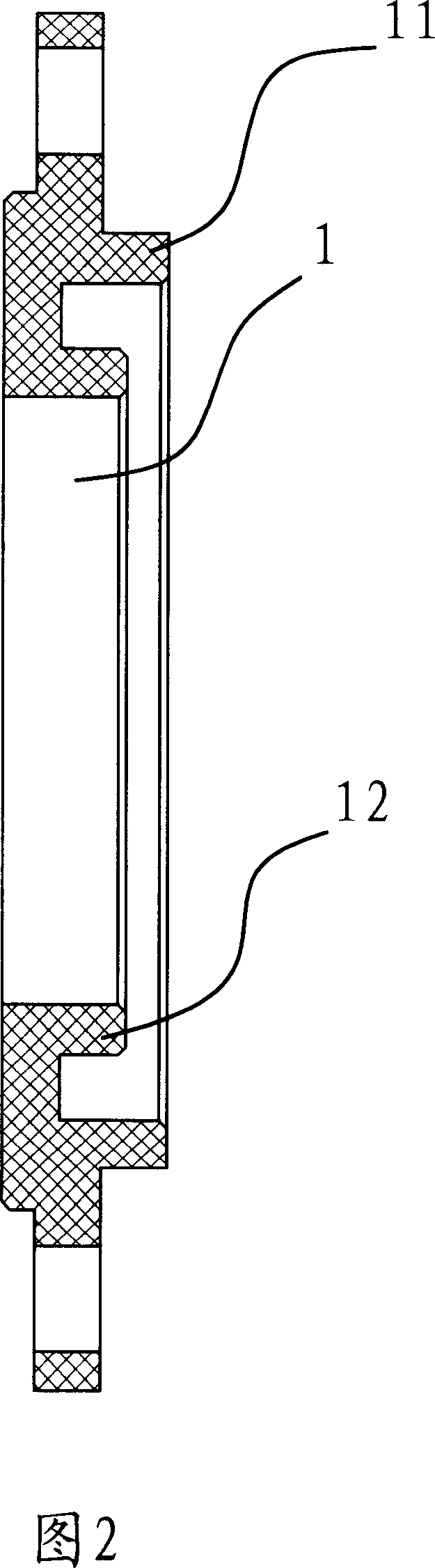

[0029] As shown in Figures 1, 2, and 3, the sealing gasket 1 and the sealing cover 2 in this sealing structure are both ring-shaped, and the opposite side of the sealing gasket 1 in contact with the pulley 4 has a large convex ring 11, and it...

Embodiment 2

[0034] As shown in Fig. 4 and Fig. 5, another form of the sealing gasket 1 and the sealing cover 2 of the present sealing structure. Wherein the large convex ring 11 and the small convex ring 12 of the gasket 1 are of the same height, and the outer wall of the sealing cover 2 has a flange 24 . Others are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com