A tram rail roof sealing layer structure and its laying process

A tram and sealing layer technology, applied in the superstructure of the track, laying the track, the track, etc., can solve the aging and cracking of the track top glue, the trouble of shoveling the track top glue, the buffering of the track top glue and the deterioration of the waterproof insulation effect, etc. problem, to achieve the effect of convenient dismantling and shoveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

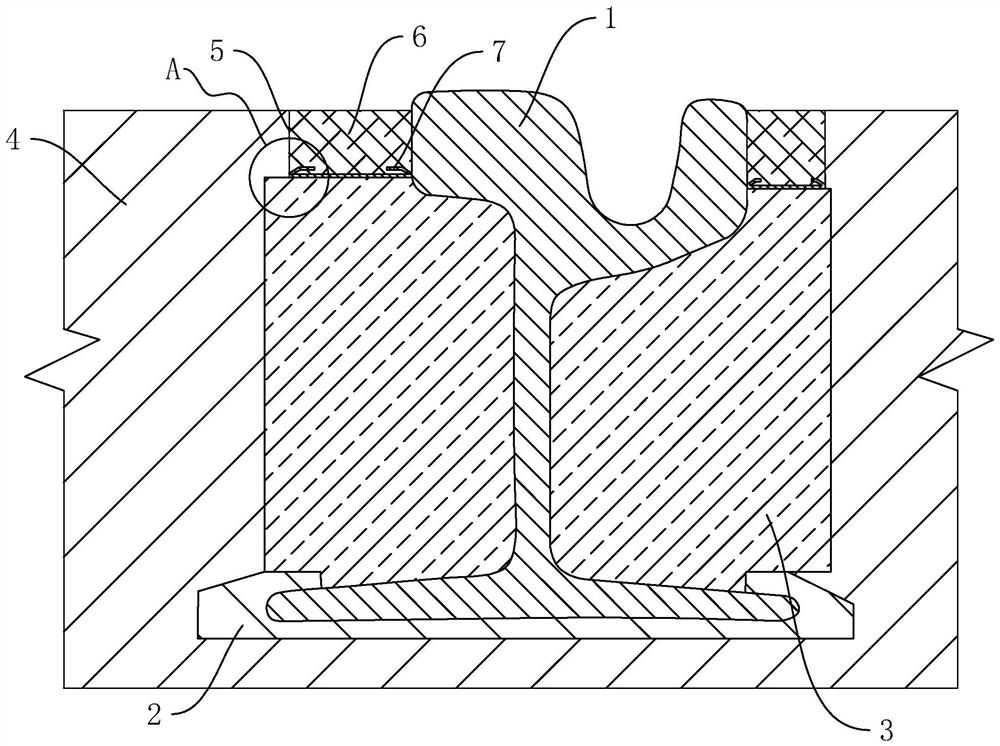

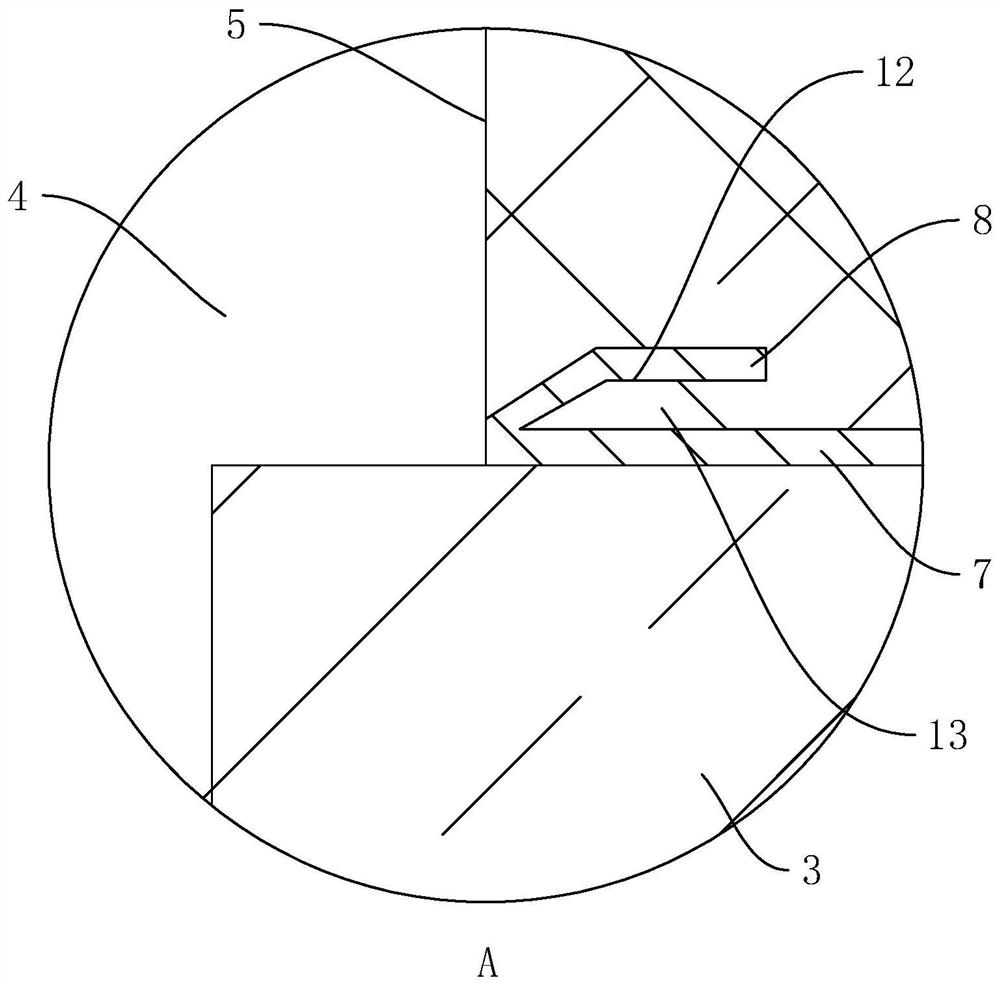

[0038] A tram rail top sealing layer structure, such as figure 1 As shown, the steel rail 1 is included, and the steel rail 1 is a grooved rail. The bottom of the rail 1 is provided with a rail bottom sheath 2, and both sides of the rail 1 are also provided with a wrapping material 3. The wrapping material 3 is usually a polymer material such as plastic or rubber. The upper end surface of the wrapping material 3 is lower than the upper end surface of the rail 1. set up. The outer side of the wrapping material 3 is also provided with a packing block 4, and the upper end surface of the packing block 4 near the side wall of the rail 1 is provided with a glue groove 5, and the bottom of the glue groove 5 is formed by splicing the packing block 4 with the wrapping material 3. The rubber groove 5 is filled with a rail top rubber strip 6, and the groove bottom of the rubber groove 5 is also provided with a pulling material strip 7, which is fixedly connected to the bottom end of the...

Embodiment 2

[0046] A laying process for a tram rail top sealing layer structure, comprising the following steps:

[0047] S1, the forming rubber groove 5, cuts the upper end surface of the steel rail 1 on both sides of the wrapped material 3 through a cutting machine. The filler between the rails 1 is broken, and the debris is cleaned to form the glue groove 5 .

[0048] S2, grinding the side wall of the rail 1, and destroying the oxide layer of the side wall of the rail 1 by sandpaper grinding, so that the roughness of the side wall of the rail 1 becomes larger, and then cleaning by blowing air.

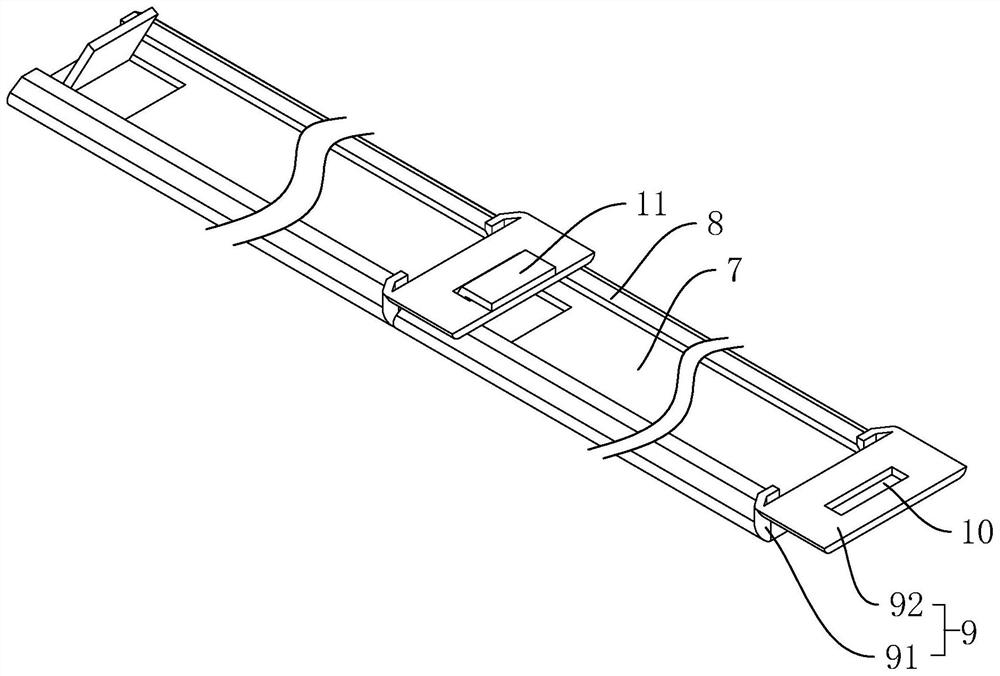

[0049] S3, laying the tearing material strip 7, laying the tearing material strip 7 along the glue groove 5, laying the tearing material strip 7 in sequence, and marking the marking line at the joint of the steel rail 1 corresponding to the pulling material strip 7. Pull material bar 7 lower end faces and fix by the groove bottom of glue groove 5 every 300mm-500mm. The positioning strip 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com