Sand storing box

A technology of sand box and box body, which is applied in casting molding equipment, machinery for cleaning/processing of casting materials, metal processing equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

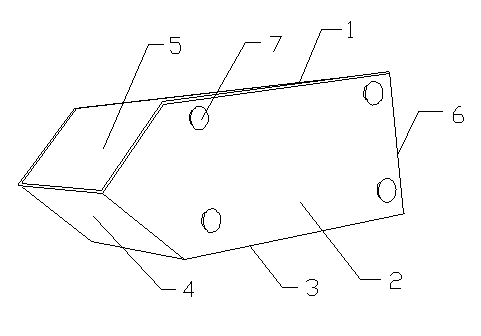

[0018] see figure 1 The sand box of the present invention includes a box body 1, a cavity 5 in the box body 1, and the box body 1 is composed of a bottom plate 3, two front and rear main side panels 2, side panels 4 and vertical panels 6, wherein the side panels The side board 4 forms an obtuse angle with the bottom board 3 , and the height of the side board 4 is lower than that of the main side board 2 .

[0019] The outer walls of the front and back two main side panels 2 are provided with a plurality of hanging panels 7, which are convenient for transportation after being put on ropes.

[0020] Since the side plate 4 and the base plate 3 form an obtuse angle, and the height of the side plate 4 is lower than the main side plate 2, workers can easily shovel out the sand in the box body 1, which saves a lot of time and improves efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com