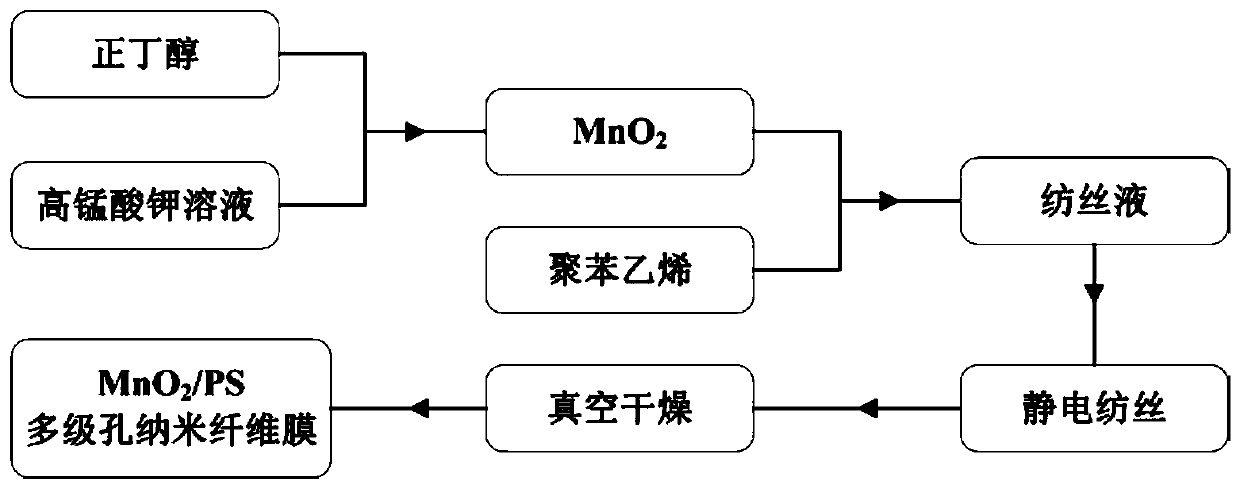

Preparation method of multifunctional synergistic hierarchical pore air purification membrane

A technology of air purification and multi-stage pores, applied in chemical instruments and methods, separation methods, membrane technology, etc., can solve the problem of low capture effect of ultrafine particles, achieve good application prospects, efficient synergistic purification, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 1.58 g KMnO 4 Place in 50 mL deionized water, stir at room temperature until KMnO 4 Dissolve completely and form KMnO 4 solution, and then added 8 mL of n-butanol, after stirring, the reactant was placed in a constant temperature water bath device, and reacted at a constant temperature of 40 °C for 2 h. Then, the reaction mixture was suction-filtered, the solid was separated and collected, and washed three times with deionized water. Finally, the collected brown MnO 2 The solid was dried in a vacuum oven at 60 °C for 24 h.

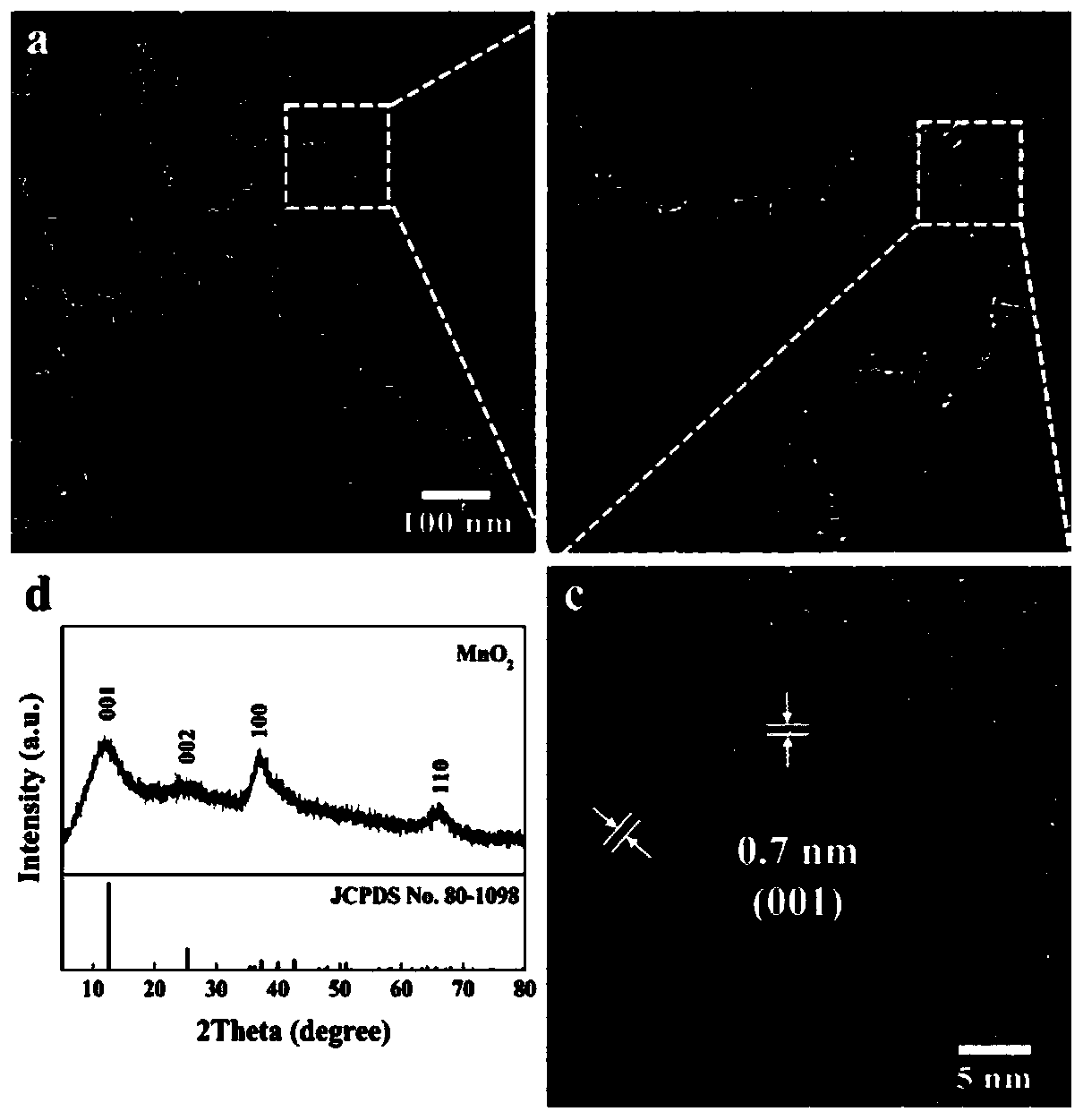

[0029] The MnO prepared in this example 2 TEM figure 2 (a-c)) and X-ray diffraction ( figure 2 (d)) analysis. from figure 2 (a-c) It can be observed that MnO 2 The nanoparticles are spherical, assembled from nanosheets with unclear boundaries, and have obvious lattice fringes, and the fringe spacing is about 0.7 nm, which is similar to that of birnessite-type δ-MnO 2 corresponding to the (001) crystal plane; from figure 2 (d) Ob...

Embodiment 2

[0031] Weigh 3.16 g KMnO 4 Place in 50 mL deionized water, stir at room temperature until KMnO 4 Dissolve completely and form KMnO 4 solution, and then added 8 mL of n-butanol, after stirring, the reactant was placed in a constant temperature water bath device, and reacted at a constant temperature of 60 °C for 0.5 h. Then, the reaction mixture was suction-filtered, the solid was separated and collected, and washed three times with deionized water. Finally, the collected brown MnO2 The solid was dried in a vacuum oven at 60 °C for 24 h.

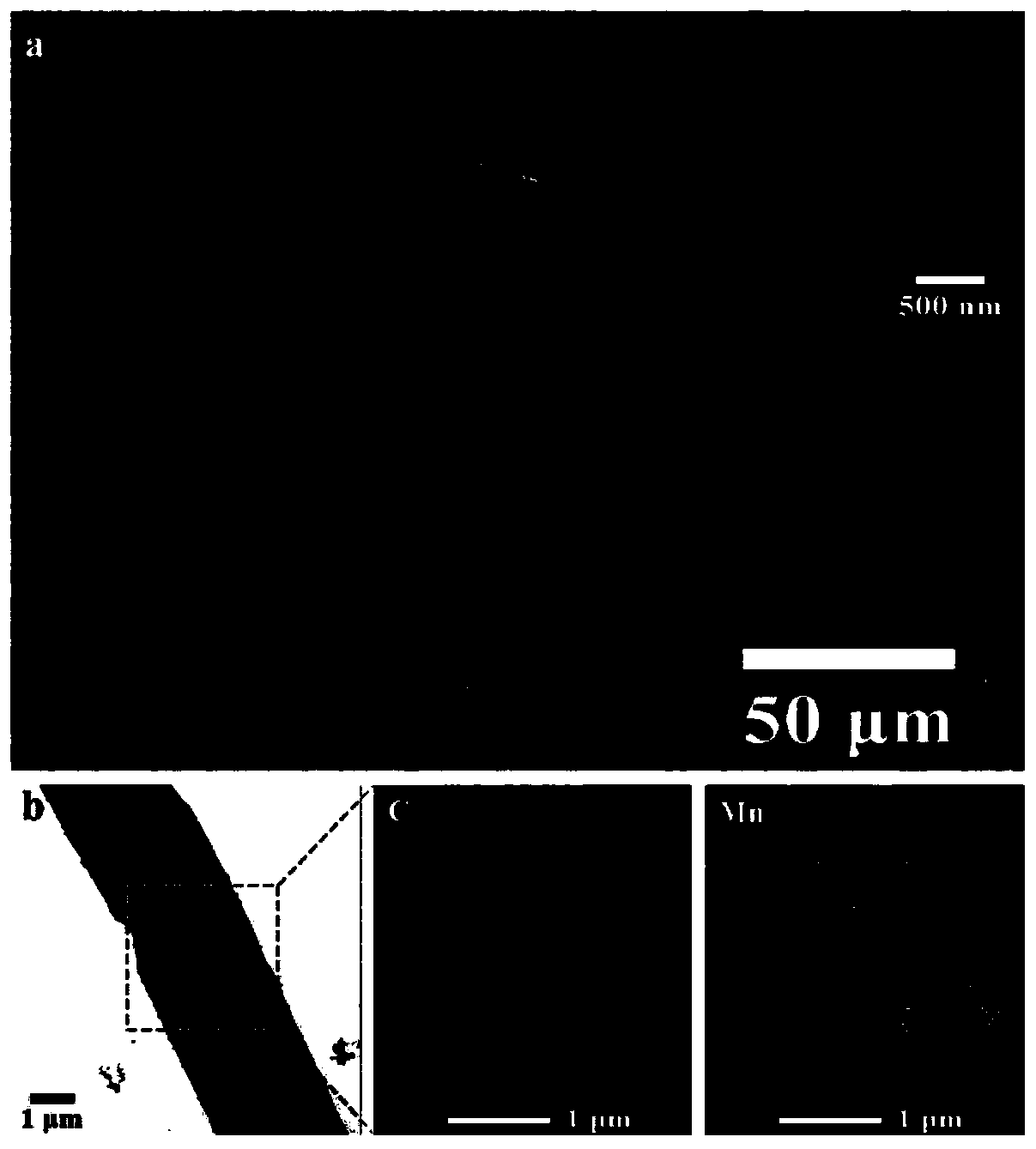

[0032] Take the MnO prepared above 2 Nanoparticles 0.3 g solid was ground into a fine powder in an agate mortar and added to 7.2 g N,N - in dimethylformamide, placed in a sonicator for 30 min to make MnO 2 fully dispersed in N,N -Add 1.8 g of tetrahydrofuran and 1 g of polystyrene particles to dimethylformamide, stir at room temperature until the polystyrene is completely dissolved, and prepare a spinning solution with a mass fraction o...

Embodiment 3

[0035] Weigh 2.37 g KMnO 4 Place in 50 mL deionized water, stir at room temperature until KMnO 4 Dissolve completely and form KMnO 4 solution, and then added 8 mL of n-butanol, after stirring, the reactant was placed in a constant temperature water bath device, and reacted at a constant temperature of 25 °C for 3 h. Then, the reaction mixture was suction-filtered, the solid was separated and collected, and washed three times with deionized water. Finally, the collected brown MnO 2 The solid was dried in a vacuum oven at 60 °C for 24 h.

[0036] Take the MnO prepared above 2 0.05 g of nanoparticles was ground into a fine powder in an agate mortar and added to 1.6 g N,N - in dimethylformamide, placed in a sonicator and sonicated for 5 min to make MnO 2 fully dispersed in N,N -Add 2.4 g of tetrahydrofuran and 1 g of polystyrene particles to dimethylformamide, stir at room temperature until the polystyrene is completely dissolved, and prepare a spinning solution with a poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com