Method for preparing biomass base film by taking strip-shaped graphene oxide as binder

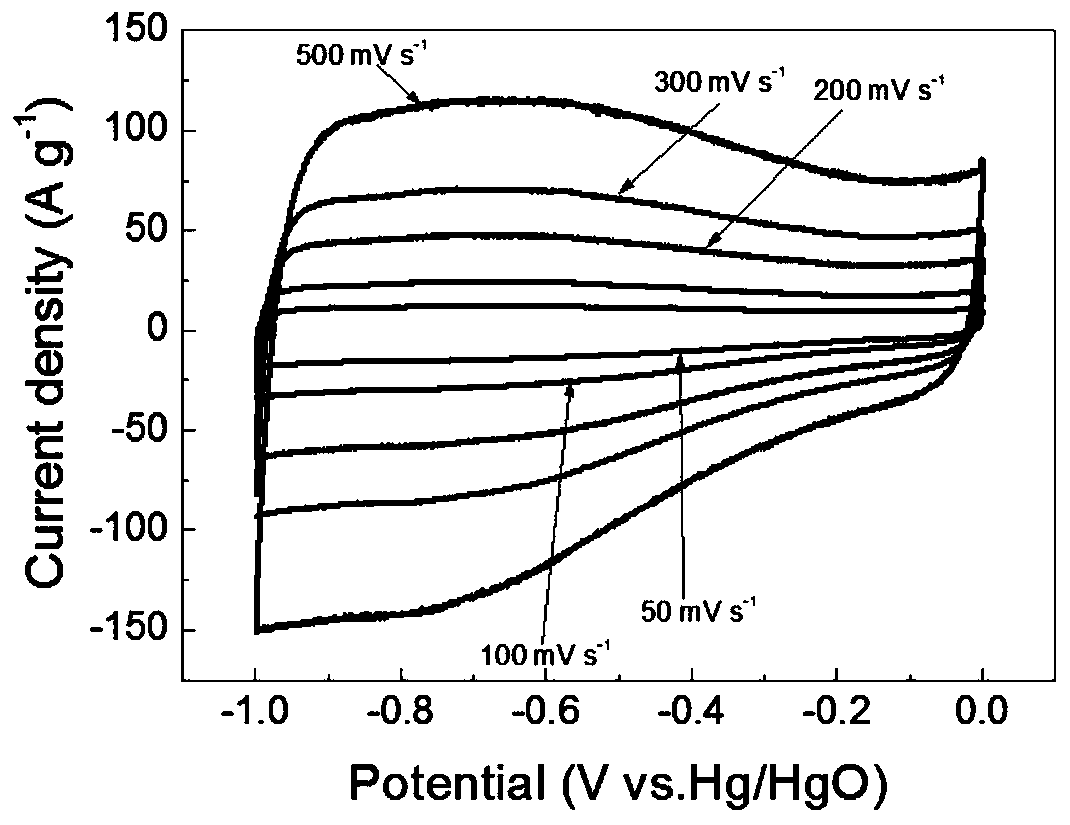

A binder preparation and strip-shaped technology, which is applied in the field of flexible membrane materials, can solve the problems that flexible electrodes cannot be used directly, and achieve the effects of enhancing electrochemical performance, improving mechanical strength, and reducing diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of strip-shaped graphene oxide prepares the method for biomass-based film as binding agent, specifically comprises the following steps:

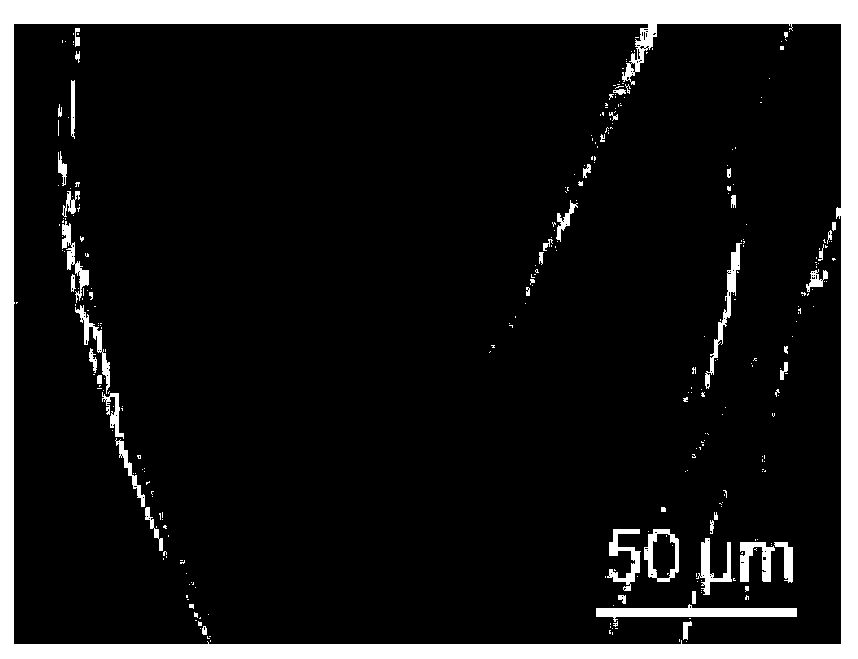

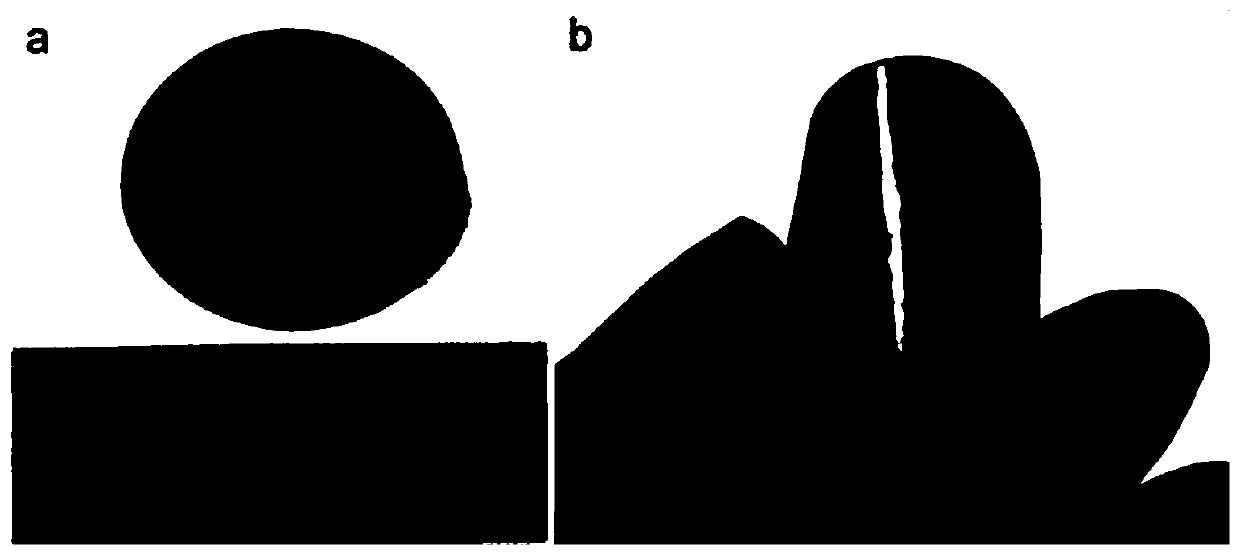

[0040] 1) Preparation of biomass carbon tubes: using the one-dimensional tubular structure as the raw material, put it in a tube furnace, and carry out carbonization and calcining under a nitrogen atmosphere, with a heating rate of 5 °C min -1 , the calcination temperature is 800°C, and the holding time is 2h; the obtained biomass carbon precursor is mixed with potassium hydroxide at a mass ratio of 1:2, then placed in a tube furnace, and activated for calcination under a nitrogen atmosphere , the heating rate is 5°C min -1 , the calcination temperature is 800°C, and the holding time is 2h; -1 Mixed, the mixed solution includes deionized water and 68% nitric acid in a volume ratio of 2:1. Then it was transferred to a high-pressure reactor for hydrothermal oxidation treatment, the hydrothermal temperature was 120°C, and the ho...

Embodiment 2

[0046] A kind of strip-shaped graphene oxide prepares the method for biomass-based film as binding agent, specifically comprises the following steps:

[0047] 1) Preparation of biomass carbon tubes: Catkins with a one-dimensional tubular structure were used as raw materials, placed in a tube furnace, carbonized and calcined in a nitrogen atmosphere, and the heating rate was 10 °C min -1 , the calcination temperature is 1000°C, and the holding time is 1h; the obtained biomass carbon precursor is mixed with potassium hydroxide at a mass ratio of 1:4, then placed in a tube furnace, and activated for calcination under a nitrogen atmosphere , the heating rate is 10°C min -1 , the calcination temperature is 1000℃, and the holding time is 1h; -1 Mixed, the mixed solution includes deionized water and 68% nitric acid in a volume ratio of 5:1. Then move it into a high-pressure reactor for hydrothermal oxidation treatment, the hydrothermal temperature is 150°C, and the holding time is ...

Embodiment 3

[0053] A kind of strip-shaped graphene oxide prepares the method for biomass-based film as binding agent, specifically comprises the following steps:

[0054] 1) Preparation of biomass carbon tubes: Cotton with a one-dimensional tubular structure was used as raw material, placed in a tube furnace, carbonized and calcined in a nitrogen atmosphere, and the heating rate was 2 °C min -1 , the calcination temperature is 700°C, and the holding time is 4h; the obtained biomass carbon precursor is mixed with potassium hydroxide at a mass ratio of 1:1, then placed in a tube furnace, and activated for calcination under a nitrogen atmosphere , the heating rate is 2°C min -1 , the calcination temperature is 900°C, and the holding time is 2h; -1 Mixed, the mixed solution includes deionized water and 68% nitric acid in a volume ratio of 3:1. Then move it into a high-pressure reactor for hydrothermal oxidation treatment, the hydrothermal temperature is 100°C, and the holding time is 4h; af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com