Mixing equipment for coating material dilution

A technology for mixing equipment and coatings, applied in mixers, mixers with rotating stirring devices, dissolving, etc., can solve the problems of ineffective dilution and affecting the color of coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0026] A mixing device for paint thinning, such as Figure 1-3 As shown, it includes a box frame 1, a stirring box 3, a storage box 4, an injection funnel 5, a discharge pipe 6, a rotary regulating valve 61, a sealing assembly 7, a quantitative feeding assembly 8 and a stirring assembly 9, and the box body There is a placement groove 2 on the left side of the top of the frame 1, and a mixing box 3 is installed on the right side of the top of the box frame 1 through bolts. It is semi-circular, the top of the material storage box 4 is connected to the liquid injection funnel 5, the bottom of the mixing box 3 is connected to the discharge pipe 6, the discharge pipe 6 is provided with a rotary regulating valve 61, and the right side of the stirring box 3 is installed with a sealing assembly 7. Quantitative feeding assembly 8 is installed in storage box 4, and stirring assembly 9 is installed at the bottom of stirring box 3.

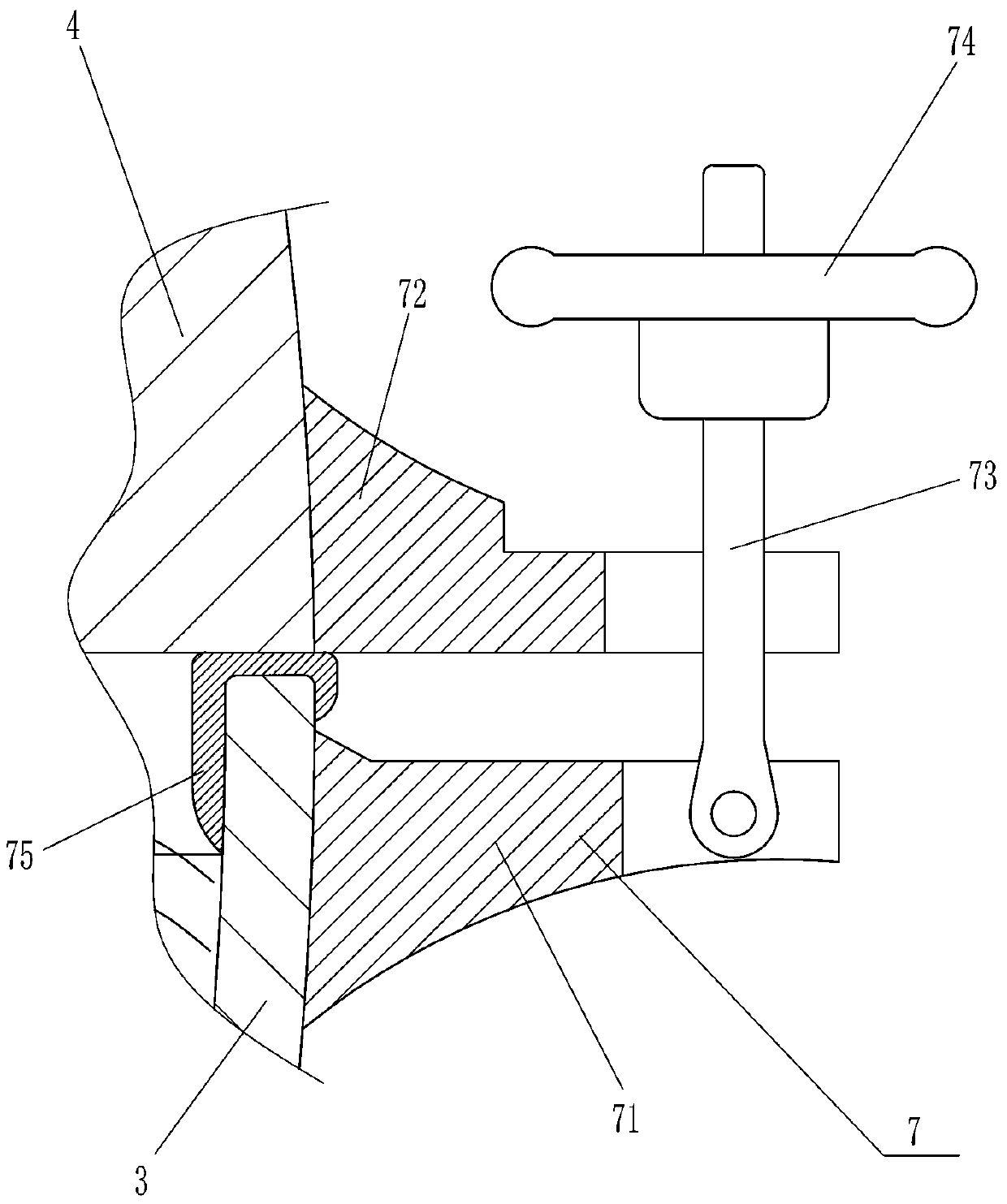

[0027] The sealing assembly 7 includes a first fixed b...

Embodiment approach 2

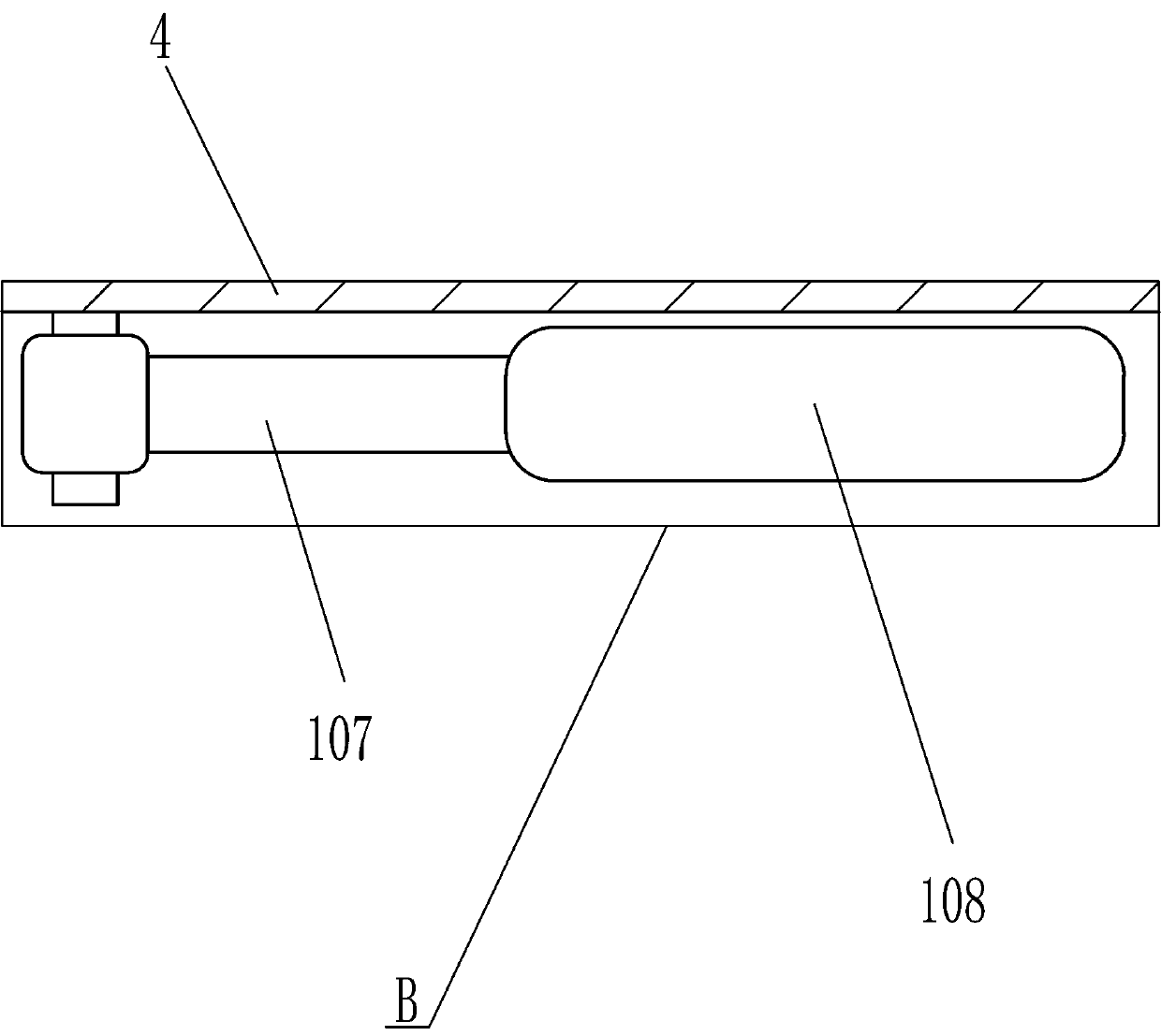

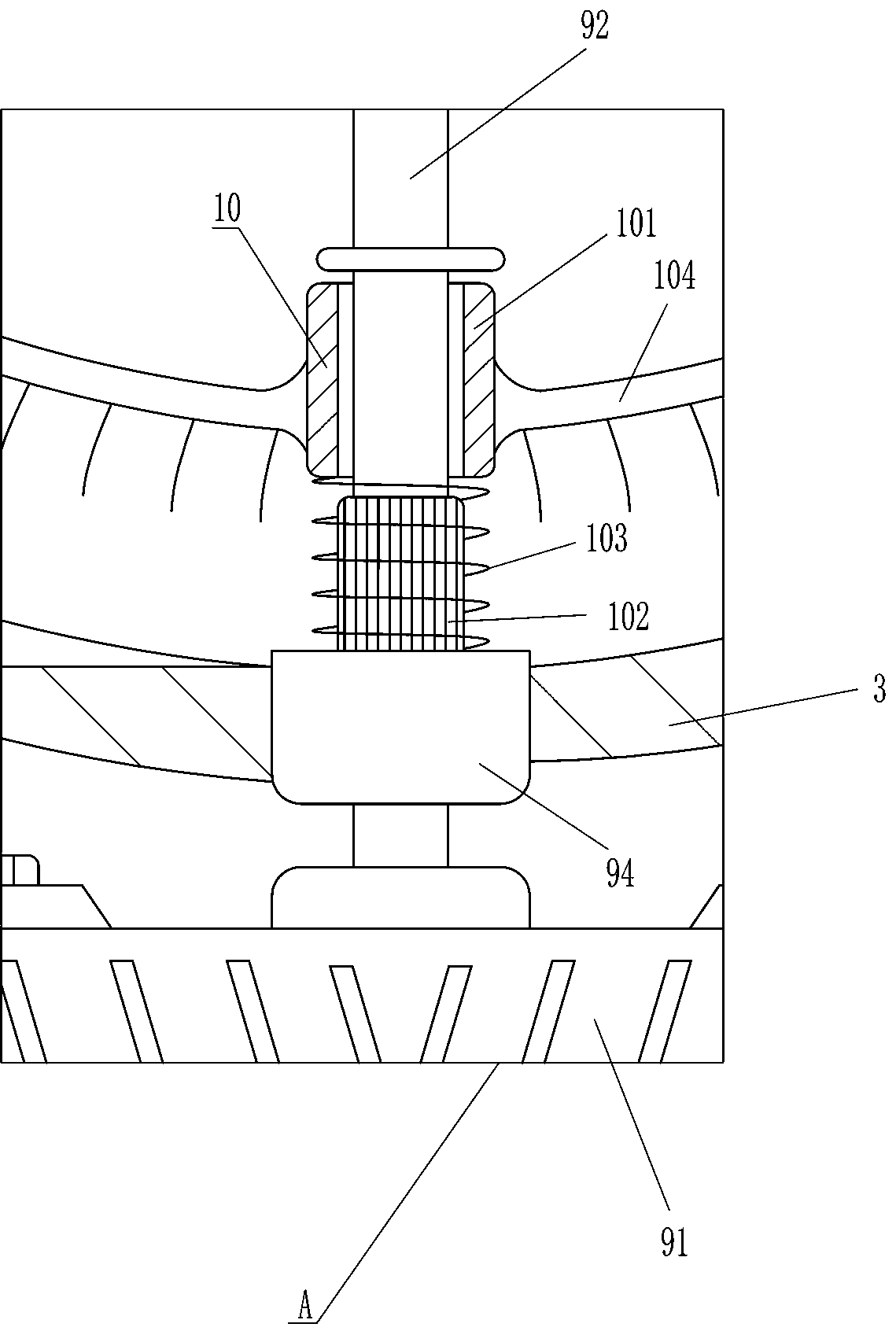

[0035] On the basis of Embodiment 1, if figure 1 , image 3 , Figure 4 and Figure 5 As shown, a cleaning mechanism 10 is also included, and the cleaning mechanism 10 includes a ring gear 101, a gear rod 102, a first spring 103, a brush rod 104, an oblique bracket 105, a contact rod 106, a hinged rod 107 and a contact plate 108. The rod 92 is covered with a gear ring 101, the lower part of the rotating rod 92 is connected with a gear rod 102, the bottom of the gear ring 101 is connected with a first spring 103, the gear rod 102 passes through the first spring 103, and the left and right sides of the gear ring 101 are connected with hair Brush rod 104, two hair brush rods 104 are arc-shaped, the inner side of hair brush rod 104 is connected with oblique support 105, is connected with contact rod 106 through bearing seat rotation type between two oblique support 105, storage box 4 bottom right The side is hingedly connected with a hinged rod 107 , and the right end of the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com