Biomass fluidized bed direct combustion system and denitration method thereof

A technology of biomass and fluidized bed, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burned in molten state, etc. It can solve the problems of inability to meet the requirements of ultra-clean emission of nitrogen oxides, corrosion of the heating surface at the tail of the reducing agent, and inability to Achieve economic benefits and other issues, achieve the effect of reducing the furnace footprint, increasing the residence time, and preventing short circuit phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

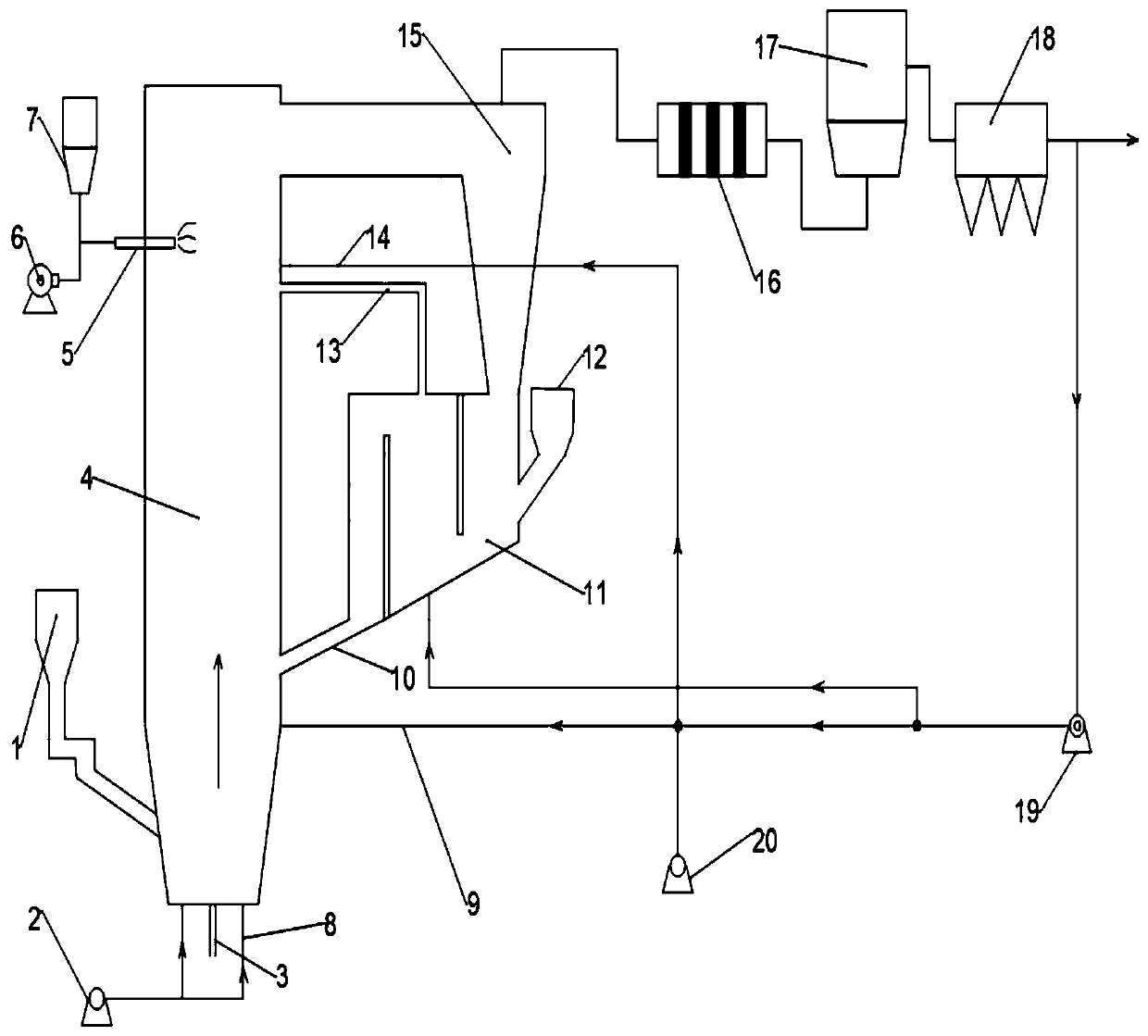

[0044] The bed material at the bottom of the biomass fluidized bed boiler 4 has a static height of 1.2m, and biomass (straw, wood chips) of 20 to 40 meshes is taken as a part of the raw material to enter the biomass fluidized bed boiler 4 from the first feeder 1. Fluidization and combustion under the air supply of 2, the ash obtained during the combustion process is discharged from the slag discharge pipe 3, and the unburned biomass particles and bed materials still carry a large amount of heat, and are separated by the cyclone separator 15 and then enter the return reactor 11 .

[0045] The other part of the biomass raw material enters the feed-back reactor 11 from the second feeder 12, and is gasified by using the heat of the above-mentioned biomass hot particles under the micro positive pressure working condition of 0-5% oxygen concentration and 1-5KPa reaction, the gasified gas (H 2 、C x h y , CO, etc.) enter the denitrification reaction zone of the boiler from the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com