Bottom wrapping type vibration hammer profile steel pile pulling machine and pile pulling method thereof

A technology of steel pile pulling machine and vibrating hammer, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of prolonging the construction period, consuming a certain amount of time, reducing construction efficiency, etc., so as to improve work efficiency and fast sinking speed. , The effect of saving the shift fee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

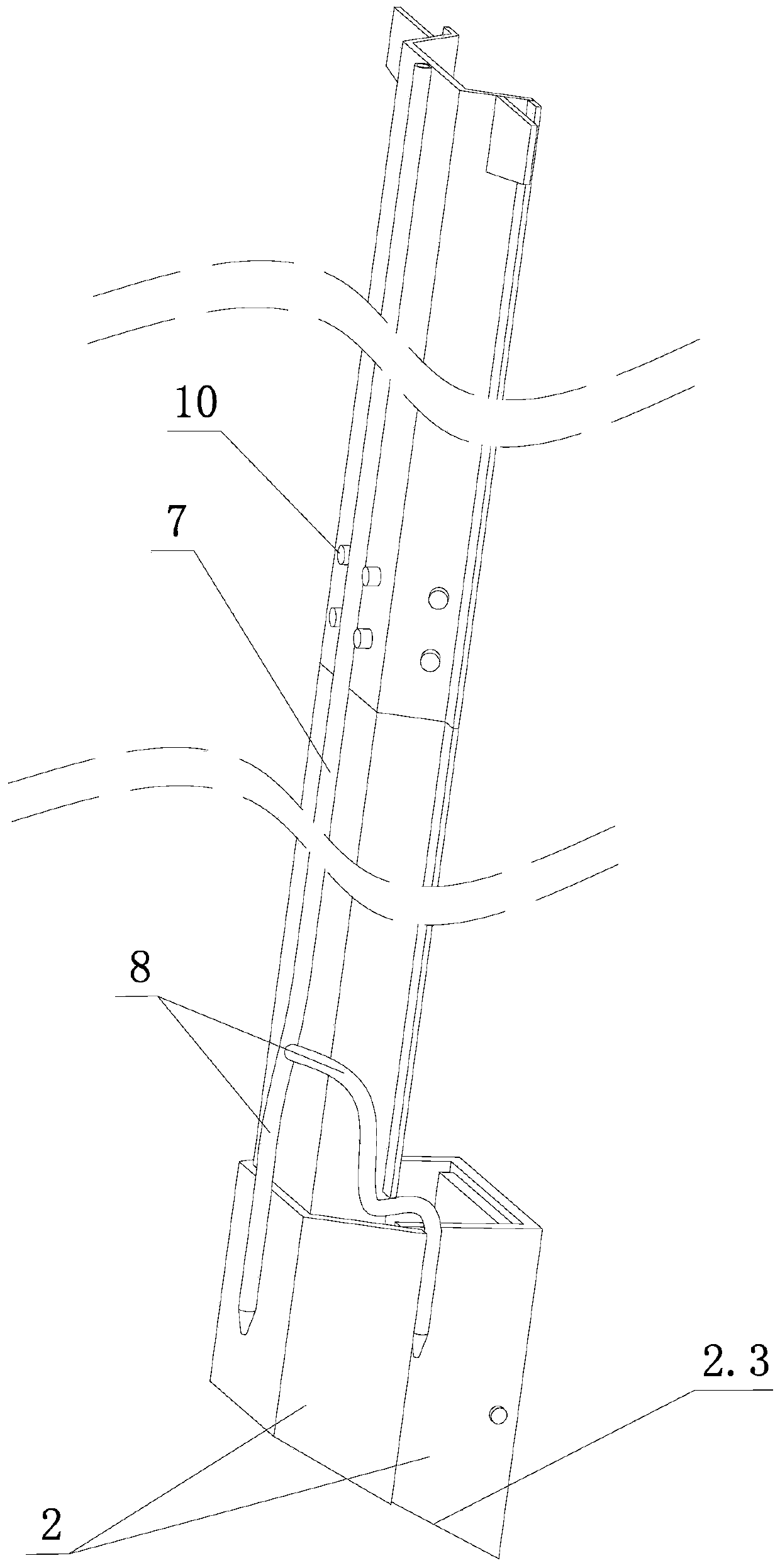

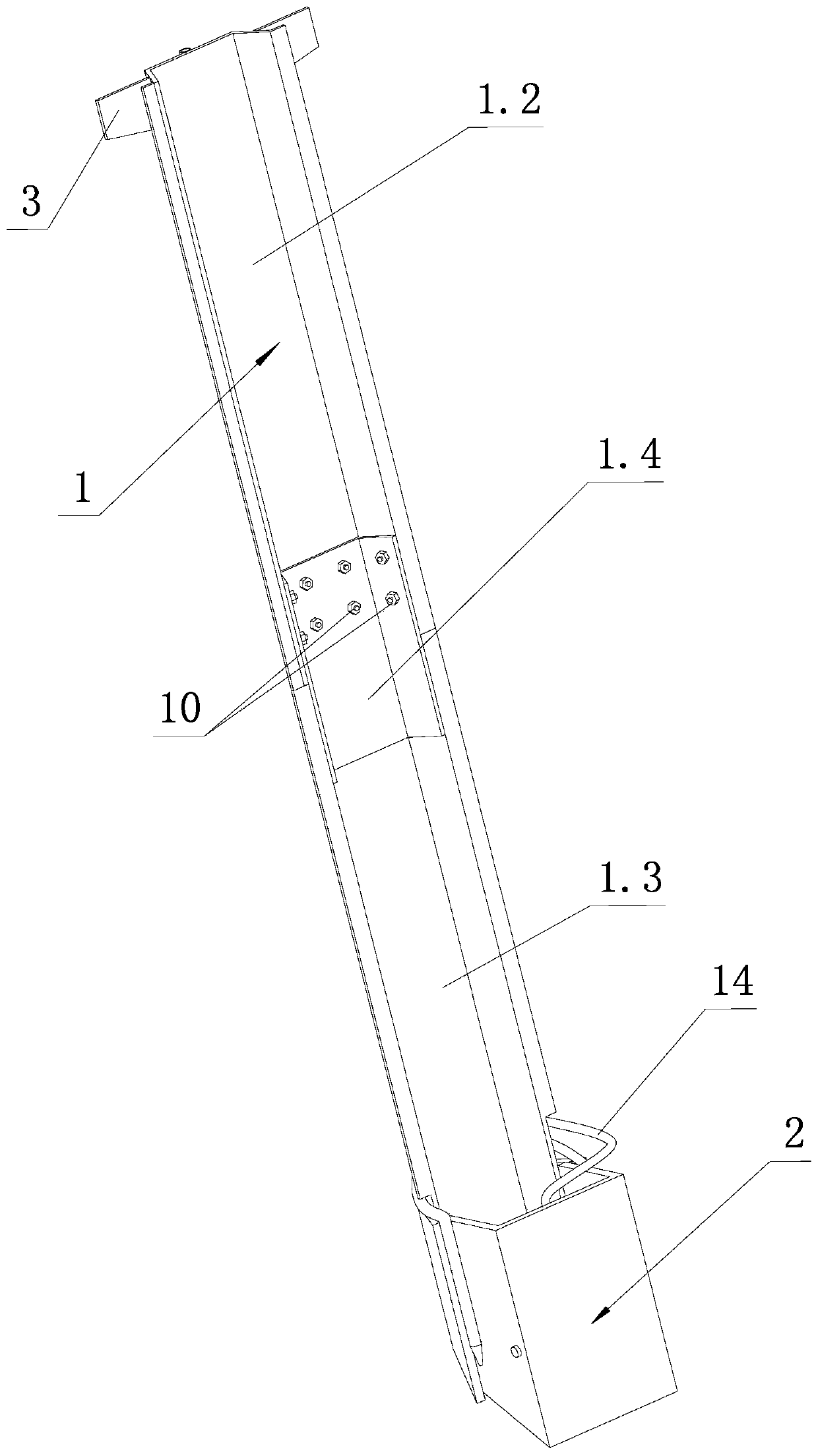

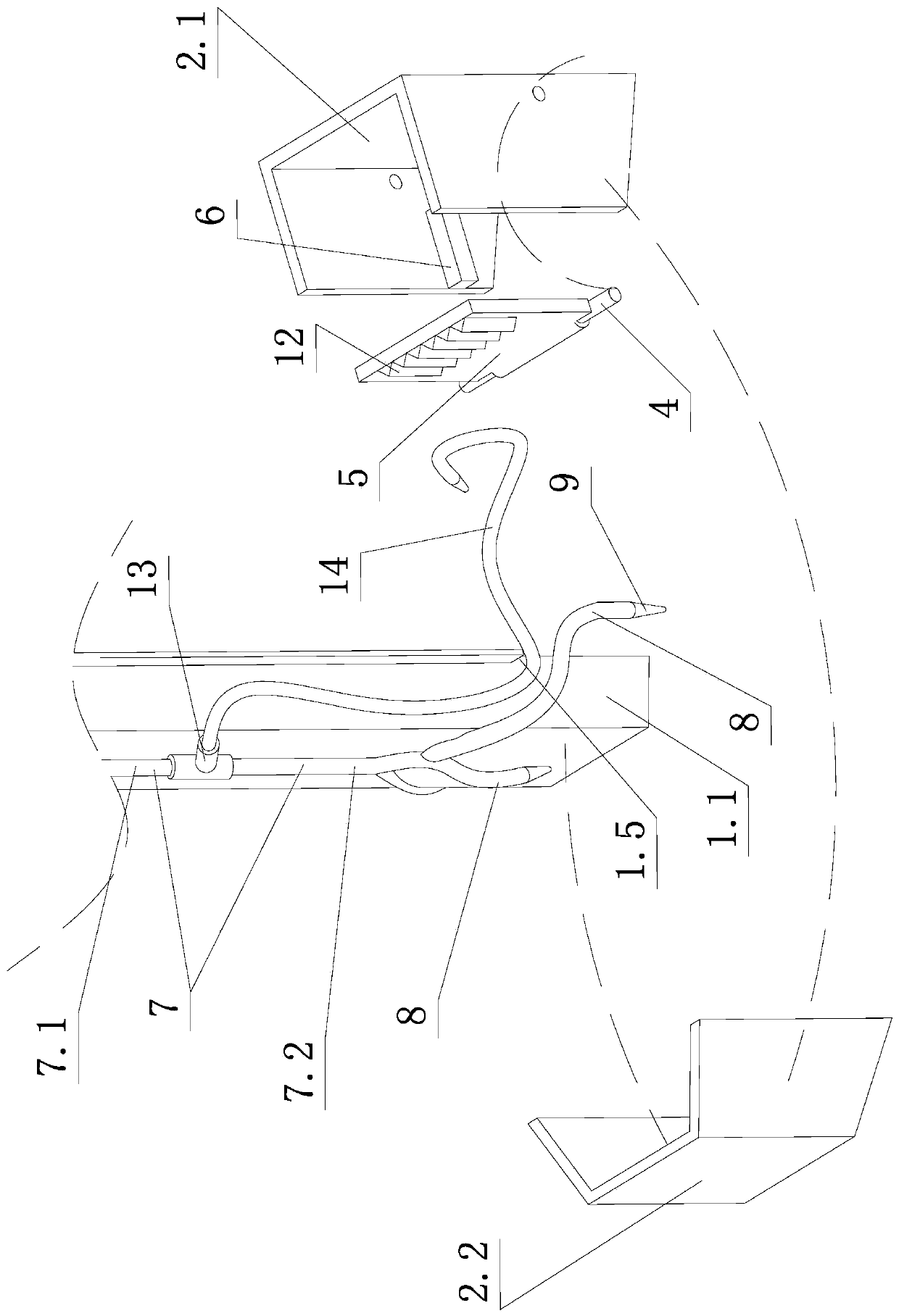

[0031] Such as Figure 1 to Figure 7 Shown, the bottom type vibrating hammer type steel pile extractor of the present invention, it comprises the rod part 1 that is made of Larsen type steel and the pile sleeve 2 that is positioned at the rod part 1 bottom.

[0032] The rod part 1 includes the upper section Larsen type steel 1.2 and the lower section Larsen type steel 1.3, the front side of the lower section Larsen type steel 1.3 is welded with an open connection groove steel plate 1.4, and the open connection groove steel plate 1.4 is connected to the upper section through the bolt 10. Sen type steel 1.2 connection. The opening of the Larsen type steel of the rod part 1 faces forward, and the upper end of the upper section of the Larsen type steel 1.2 of the rod part 1 is welded with an ear plate 3 for connecting a vibratory hammer.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com