Method for preparing five ferulate single components by taking soapstock containing oryzanol as raw material

A technology of ferulic acid ester and oryzanol, applied in the field of plant extraction and separation, can solve the problems of high cost, difficult preparation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1) Alkali alcohol hot melt and filter while hot. Put 100.3g of oryzanol-containing soapstock raw material into a 1000mL beaker, add 800mL of methanol, heat in a water bath at 52°C, and stir frequently until the temperature inside and outside the beaker is consistent. Then use 4% sodium hydroxide aqueous solution to adjust the pH of the system to 10.0, keep it warm at 52°C and keep stirring for 10 minutes, until the gluten soap base is dissolved and the insoluble matter is clearly separated, centrifuge while it is hot, and centrifuge at 3500 rpm for 5 minutes , collect the centrifugate to obtain the dissolved filtrate.

[0060] 2), acid precipitation and filtration. Adjust the pH of the dissolved filtrate to 7.0 with dilute hydrochloric acid with a concentration of 10%. After stirring for 5 minutes, let it stand still to precipitate a precipitate. Continue to stand still for 4 hours, filter with suction, and collect the precipitate to obtain 62.5 g of a yellow precipita...

Embodiment 2

[0078] 1) Alkali alcohol hot melt and filter while hot. Put 200.9g of oryzanol-containing soapstock raw material into a 2000mL beaker, add 1500mL of ethanol, heat in a water bath at 56°C, and stir frequently until the temperature inside and outside the beaker is consistent. Then use 5% potassium hydroxide aqueous solution to adjust the pH of the system to 9.5, keep it warm at 56°C and keep stirring for 12 minutes, until the gluten soap base is dissolved and the insoluble matter is separated obviously, suction filter while it is hot, and collect the filtrate to obtain the dissolved filtrate .

[0079] 2), acid precipitation and filtration. Adjust the pH of the dissolved filtrate to 6.8 with dilute sulfuric acid with a concentration of 5%. After stirring for 3 minutes, let it stand to precipitate the precipitate. Continue to stand for 5 hours, centrifuge at 3500 rpm for 5 minutes, and collect the precipitate to obtain 131.6 g of yellow precipitate.

[0080] 3), lipophilic orga...

Embodiment 3

[0098] Other operation is the same as embodiment 1, and difference is in step 4), cancels the development of the thin-layer chromatography of step 5. for the third time and the fourth time.

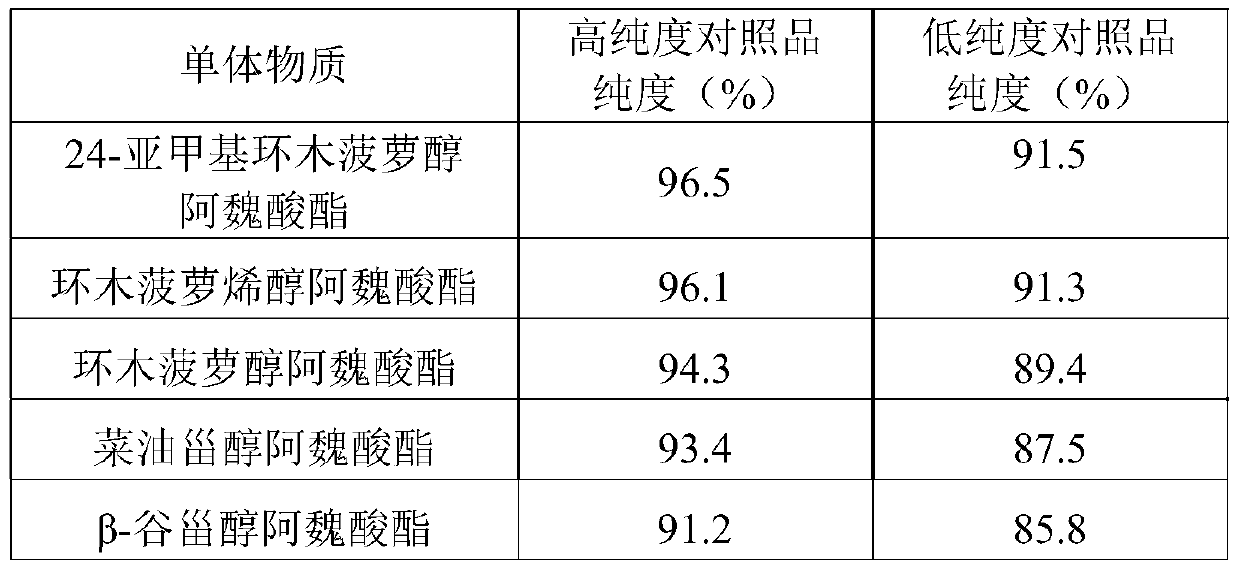

[0099] In step 4) of ⑦, the products of the high-purity group and the low-purity group were developed using thin-layer chromatography under three different conditions, methanol: isopropanol: n-hexane 1:2:2; acetone: ethyl acetate: petroleum ether 1 : 3: 4; Methanol: Ethyl Acetate: n-Hexane 1: 1: 1, spread distance 16cm, take it out to dry, and inspect with ultraviolet light, only 24-methylene cycloartenol ferulate and cycloarterol Pineapplenyl ferulic acid ester has a single spot under three different development conditions, and the other three ferulic acid ester products have multiple spots under a certain development condition, indicating that the purity of the obtained monomer has not reached 90%; The products of the low-purity group cannot all show a single spot under three different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com