Production device of isophthaloyl dichloride/paraphthaloyl chloride of sanding raw material

A terephthaloyl chloride, production equipment technology, applied in the preparation of organic compounds, carboxylate preparation, chemical instruments and methods, etc., can solve the problem of affecting the reaction speed, long reaction time, large particles of terephthalic acid materials, etc. Problems, to achieve rapid and full response, improve production efficiency, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

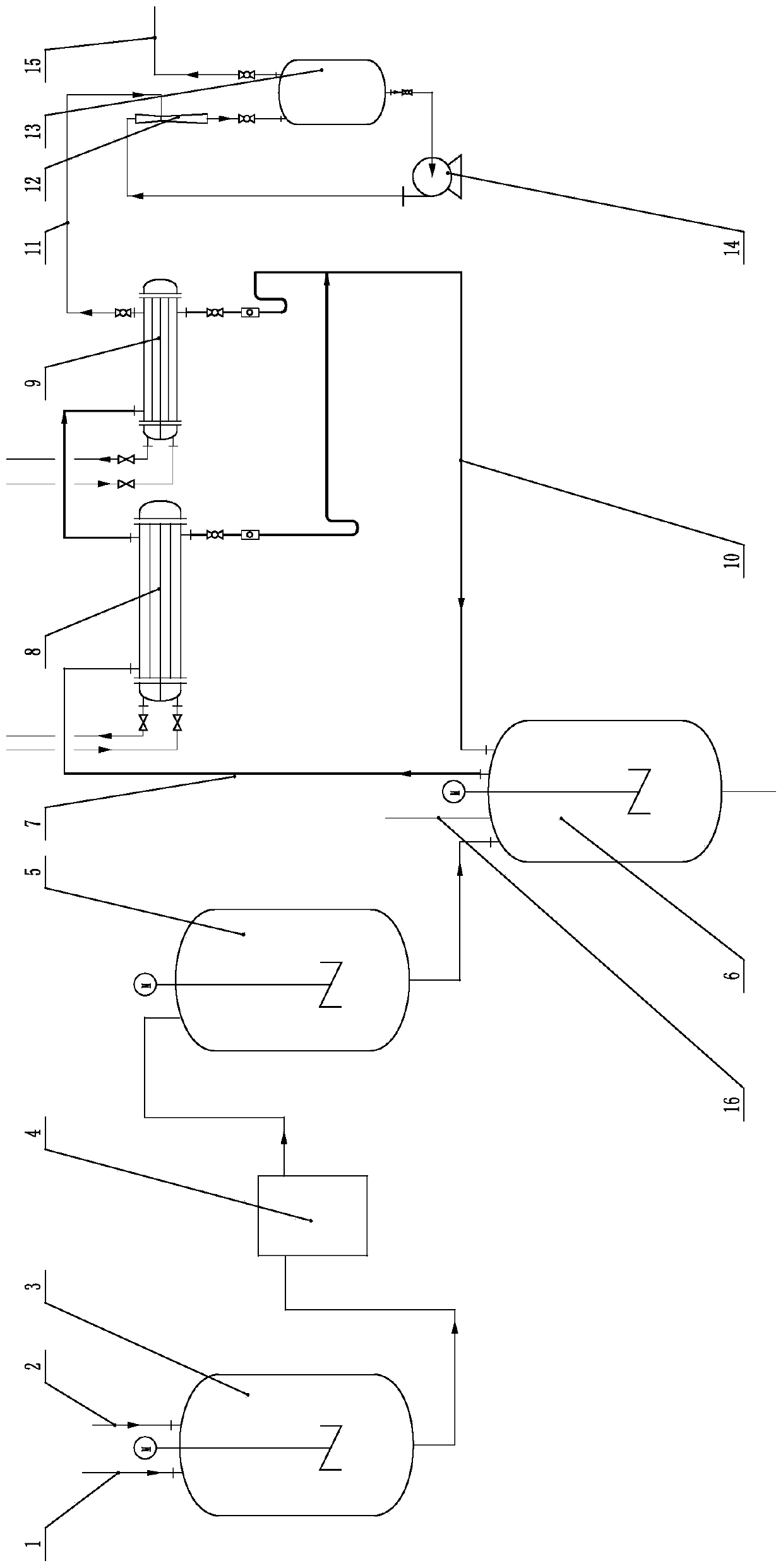

[0020] The present invention will be further described below in conjunction with accompanying drawing.

[0021] Such as figure 1 Shown, the production unit of the inter / terephthaloyl dichloride of a kind of sand mill raw material of the present invention, comprises:

[0022] A mixing tank 3 for mixing thionyl chloride and solid m / terephthalic acid, said mixing tank 3 is provided with m / terephthalic acid entering pipeline 1 and thionyl chloride feeding pipeline 2;

[0023] A sand mill 4 for grinding solid meta / terephthalic acid, the sand mill 4 communicates with the mixing tank 3 through a pipeline;

[0024] A ground material storage tank 5 for temporarily storing the mixed solution of ground solid meta / terephthalic acid and thionyl chloride, the ground material storage tank 5 is connected to the discharge end of the sand mill 4 through a pipeline;

[0025] A reaction kettle 6 for reacting m / terephthalic acid and thionyl chloride, the reaction kettle 6 communicates with the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com