Device and method for degrading VOCs (Volatile Organic Chemicals) by ultraviolet irradiation in cooperation with monatomic catalyst

A photocatalyst and ultraviolet light technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as secondary pollution, and achieve the effects of environmental degradation, improved utilization, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

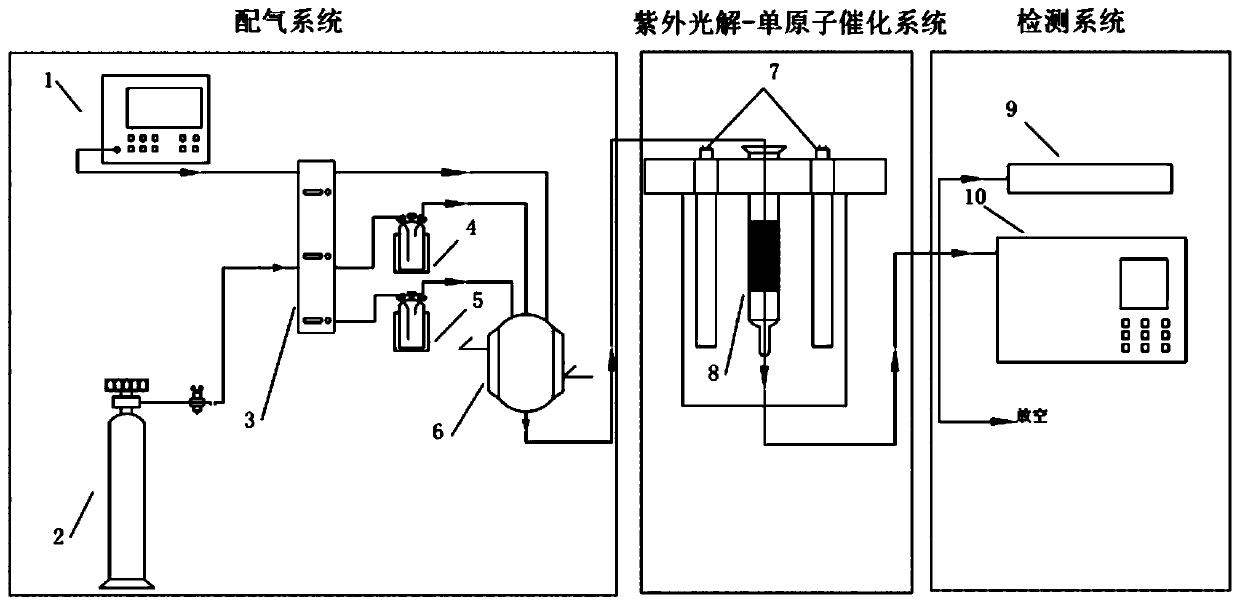

Image

Examples

Embodiment 1

[0032] Oxygen produced by an air generator is used, and two effective wavelengths are 254nm, and the effective radiation intensity of ultraviolet light is 78 μW / cm 2 The UV lamp is used as the UV light source.

[0033] Select 0.2wt%Pt / CeO 2 Single atom catalyst, 0.2wt% Pt / CeO 2 Single-atom catalyst bed height-to-reactor diameter ratio of 8, 0.2 wt% Pt / CeO 2 The ratio of the particle size of the single-atom photocatalyst to the diameter of the catalyst particle is 6.

[0034] A device and method for degrading VOCs with ultraviolet light and single-atom catalysts of the present invention, the operation steps are as follows:

[0035] (1) Gas distribution, which specifically includes the following steps: air with a flow rate of 100mL / min is mixed with nitrogen buffer gas with a flow rate of 100mL / min, then mixed with VOCs-containing nitrogen with a flow rate of 1mL / min and water vapor-containing gas with a flow rate of 1mL / min The nitrogen gas enters the mixer together for mix...

Embodiment 2

[0039] The oxygen produced by the air generator is adopted, and the effective wavelength of 254nm is adopted, and the effective radiation intensity of ultraviolet light is 78μW / cm 2 The UV lamp is used as the UV light source.

[0040] Select 0.6wt% Au / CeO 2 Single atom catalyst, 0.6wt% Au / CeO 2 Single-atom catalyst bed height to reactor diameter ratio of 9, 0.6 wt% Au / CeO 2 The ratio of the particle size of the single-atom photocatalyst to the catalyst particle diameter is 9.

[0041] A device and method for degrading VOCs with ultraviolet light and single-atom catalysts of the present invention, the operation steps are as follows:

[0042] (1) Gas distribution, which specifically includes the following steps: air with a flow rate of 1300mL / min and nitrogen buffer gas with a flow rate of 550mL / min are mixed with VOCs-containing nitrogen with a flow rate of 15.5mL / min and nitrogen gas with a flow rate of 25.5mL / min Water vapor and nitrogen enter the mixer together for mixin...

Embodiment 3

[0046] The oxygen produced by the air generator is adopted, and the effective wavelength of 254nm is adopted, and the effective radiation intensity of ultraviolet light is 78μW / cm 2 The UV lamp is used as the UV light source.

[0047] Choose 1wt%Pd / TiO 2 Single atom catalyst, 1wt% Pd / TiO 2 The ratio of the height of the single-atom catalyst bed to the diameter of the reactor is 10, 1wt% Pd / TiO 2 The ratio of the particle diameter of the single-atom photocatalyst to the diameter of the catalyst particle is 12.

[0048] A device and method for degrading VOCs with ultraviolet light and single-atom catalysts of the present invention, the operation steps are as follows:

[0049] (1) Gas distribution, which specifically includes the following steps: air with a flow rate of 2500mL / min is mixed with nitrogen buffer gas with a flow rate of 1000mL / min, then mixed with VOCs-containing nitrogen with a flow rate of 30mL / min and water vapor-containing gas with a flow rate of 50mL / min Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com