Carbon crystal electrothermal film and preparation method and application thereof

A technology of electrothermal film and carbon crystal, applied in heating element materials and other directions, can solve the problems of high energy consumption, infrared energy loss, poor particle size controllability, etc., and achieve the effects of low energy consumption, controllable energy consumption, and good flow ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

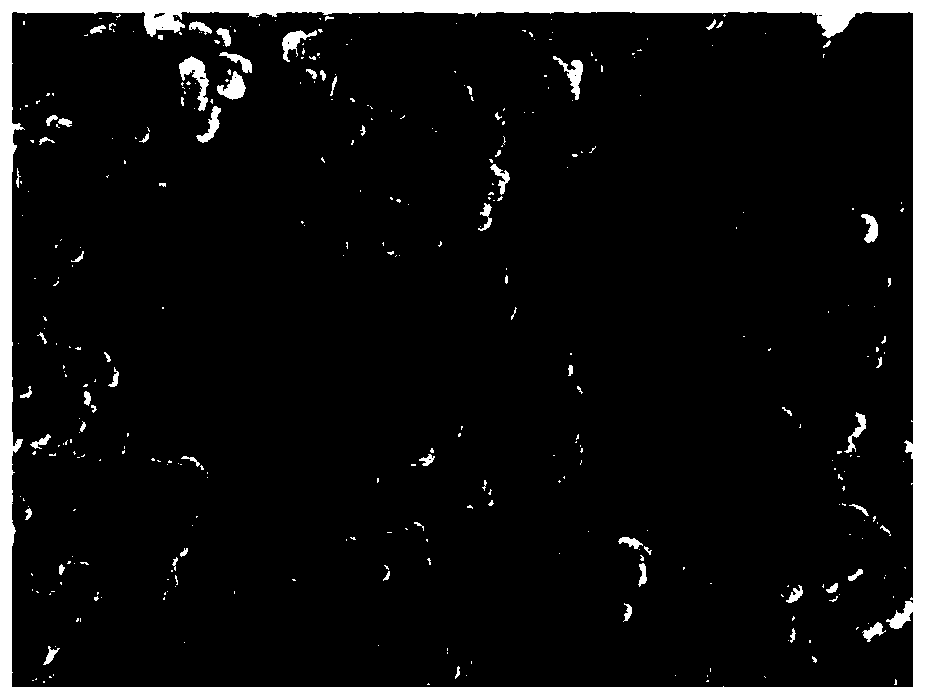

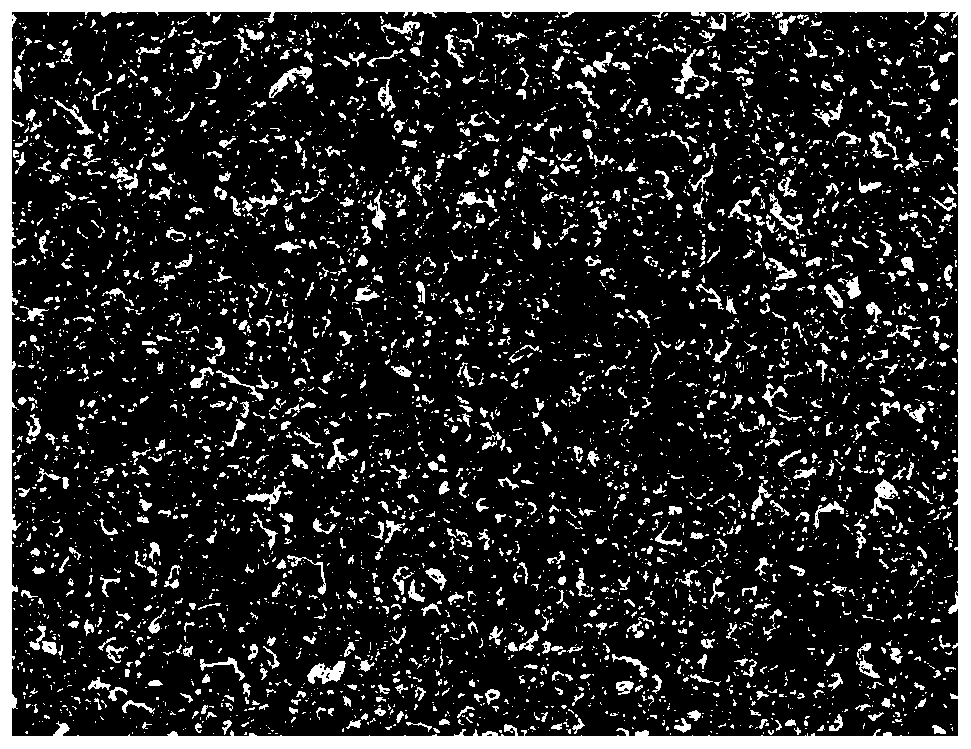

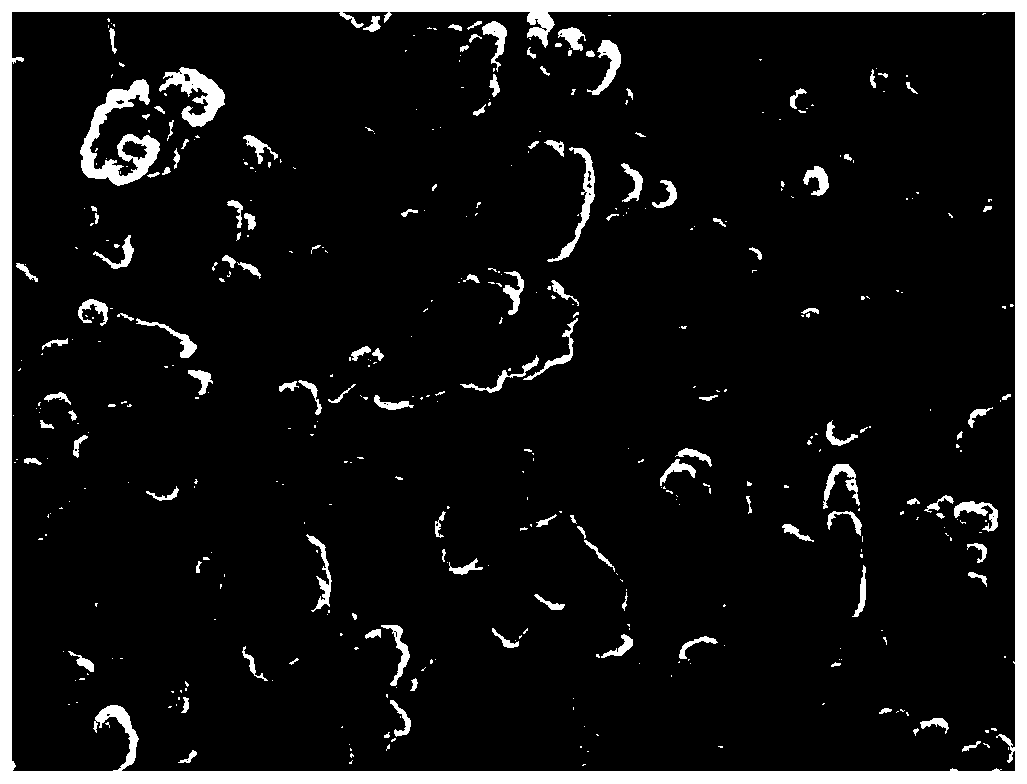

Image

Examples

Embodiment 1

[0039] Embodiment 1: the preparation method of the carbon crystal electric heating film of the present invention

[0040] (1) Preparation of carbon crystal microsphere powder:

[0041] (1-1) Add 7g of carbon fiber T300 to 200ml of ethanol, and mix;

[0042] (1-2) Add 1050 g of zirconia ball milling beads with a particle size of 0.1 mm to the mixture obtained in step (1-1) and perform ball milling until the particle size of the carbon fiber T300 is 10 nm to 100 μm and the particle size dispersibility index< 0.2, and then vacuum-dried at 45°C and -0.15MPa for 11h to obtain the carbon crystal microsphere powder with a particle size of 10nm-100μm;

[0043] (2) 7g of carbon crystal microsphere powder obtained in step (1) was added to 200ml of ethanol, and mixed uniformly under 400W ultrasound;

[0044] (3) 7g of polyethyl acrylate was added to the mixture obtained in step (2), and the mixture was uniformly mixed under 400W ultrasound;

[0045] (4) vacuum-drying the mixture obt...

Embodiment 2

[0049] Embodiment 2: the preparation method of the carbon crystal electric heating film of the present invention

[0050] (1) Preparation of carbon crystal microsphere powder:

[0051] (1-1) Add 9g of carbon nanotube material to 500ml of acetone, and mix;

[0052] (1-2) Add 157.5 g of zirconia ball milling beads with a particle size of 1 mm to the mixture obtained in step (1-1) and perform ball milling until the particle size of the carbon nanotube material is 10 nm to 100 μm and the particle size dispersibility The index is less than 0.2, and then vacuum-dried at 55°C and -0.05MPa for 13h to obtain the carbon crystal microsphere powder with a particle size of 10nm-100μm;

[0053] (2) 9g of carbon crystal microsphere powder obtained in step (1) was added to 500ml of acetone, and mixed uniformly under 400W ultrasound;

[0054] (3) 18g polyurethane was added to the mixture obtained in step (2), and the mixture was uniformly mixed under 400W ultrasonic wave;

[0055] (4) vac...

Embodiment 3

[0059] Embodiment 3: the preparation method of the carbon crystal electric heating film of the present invention

[0060] (1) Preparation of carbon crystal microsphere powder:

[0061] (1-1) 8g graphite material was added to 300ml acetone, and mixed;

[0062] (1-2) Add 2800 g of zirconia ball milling beads with a particle size of 0.1 mm to the mixture obtained in step (1-1) and perform ball milling until the particle size of the graphite material is 10 nm to 100 μm and the particle size dispersibility index < 0.2, and then vacuum-dried at 50°C and -0.05MPa for 12h to obtain the carbon crystal microsphere powder with a particle size of 10nm-100μm;

[0063] (2) 8g of carbon crystal microsphere powder obtained in step (1) was added to 300ml of acetone, and mixed uniformly under 300W ultrasound;

[0064] (3) 0.8g of polystyrene is added to the mixture obtained in step (2), and the mixture is uniformly mixed under 300W ultrasound;

[0065] (4) vacuum-drying the mixture obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com