Melamine-based externally-coated porous carbon-sulfur composite material as well as preparation method and application thereof

A melamine and composite material technology, applied in the direction of positive electrode, active material electrode, structural parts, etc., can solve the problem of uneven dispersion of active material sulfur, reduce shedding loss, stabilize porous morphology, and improve electrochemical cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a melamine-based outer coating porous carbon-sulfur composite material, comprising the following steps:

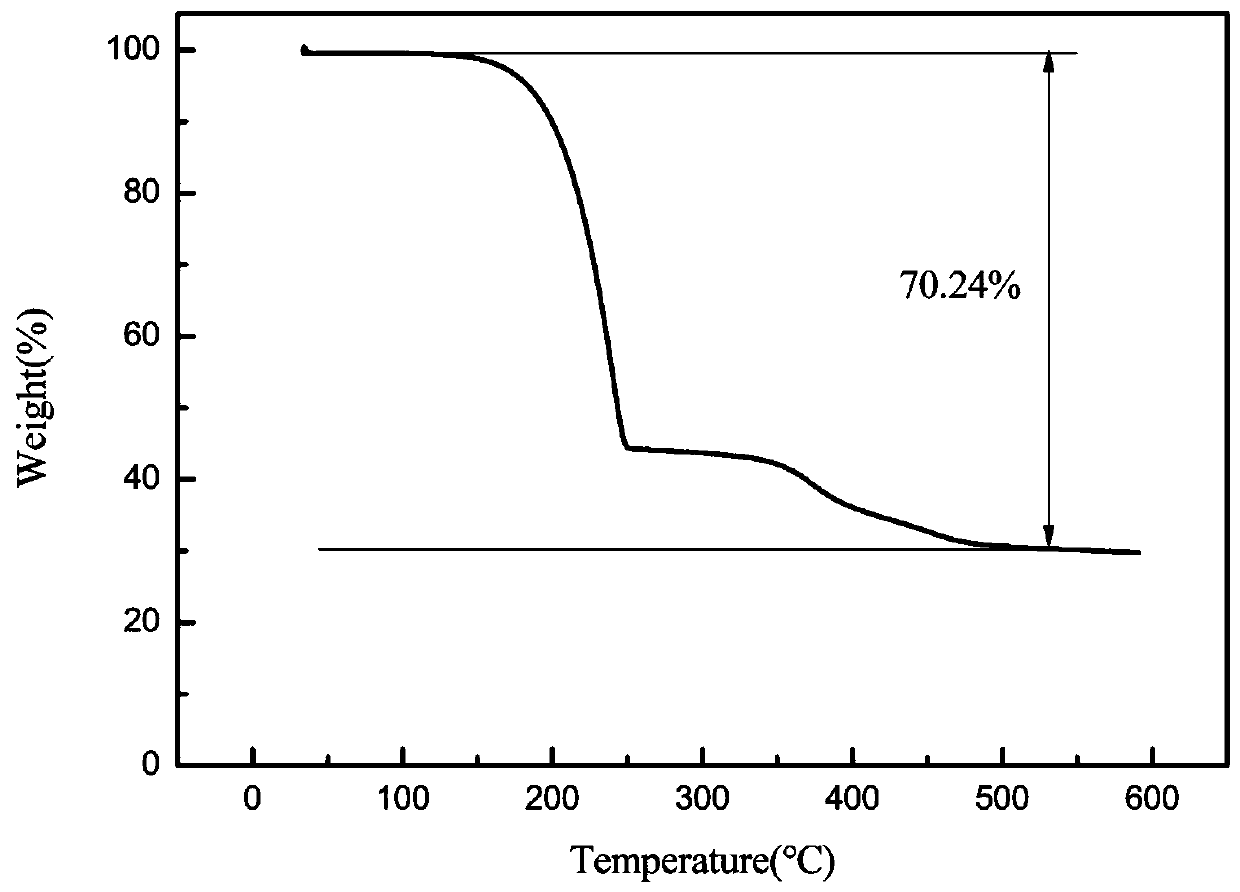

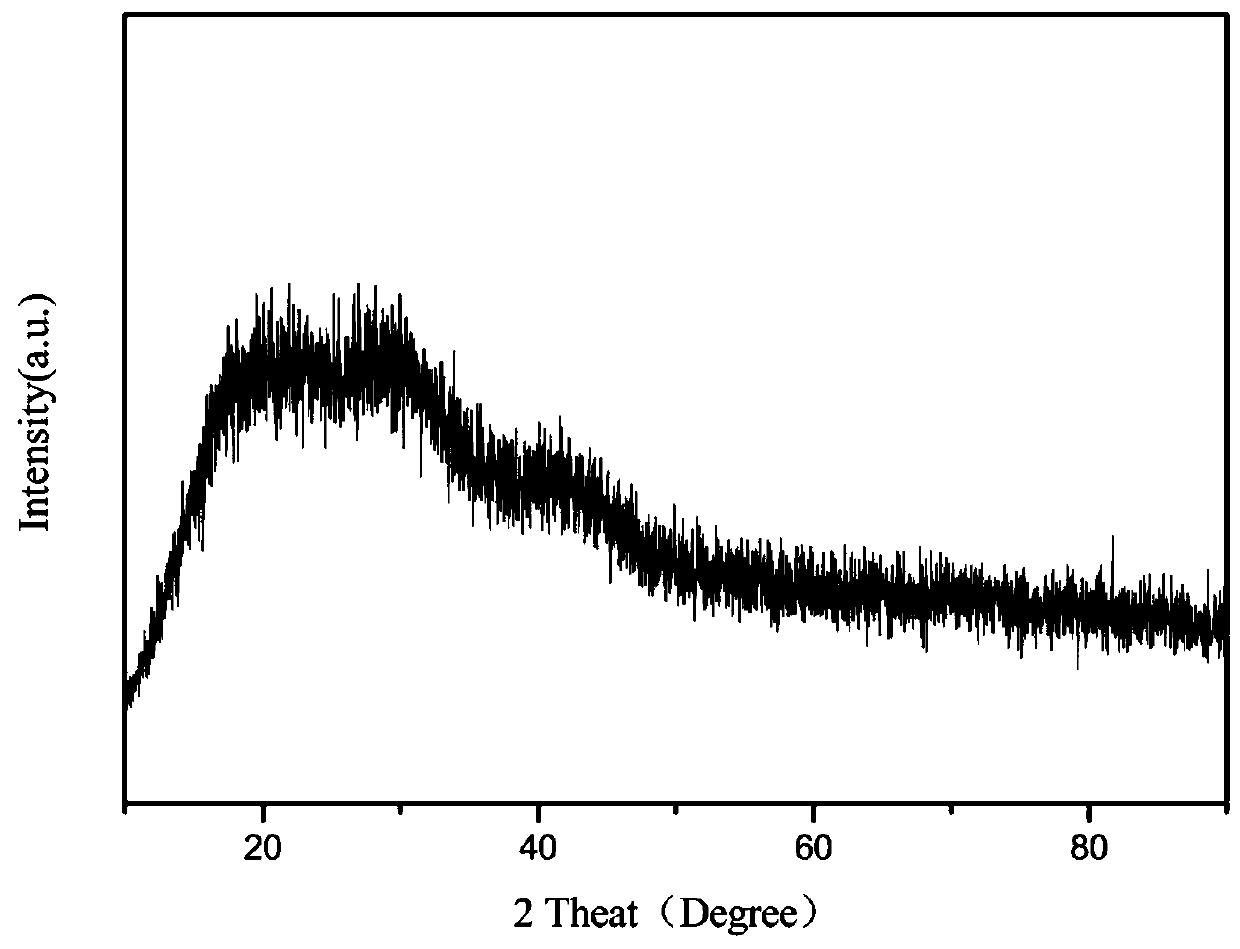

[0033] Step 1) Preparation of melamine-based porous carbon by hydrothermal method, 6.30 g of melamine was uniformly dispersed in 300 mL of distilled water to form a suspension, and 3.5 mL of phosphoric acid was added to the suspension at 60 °C, and the reaction was stirred 5–7 h, washed and dried to obtain a melamine-based porous carbon precursor. The obtained melamine-based porous carbon precursor was kept at 500 °C for 1 h under a nitrogen atmosphere, and continued to heat up to 800 °C for another 2 h to obtain a melamine-based porous carbon;

[0034] Step 2) Preparation of melamine-based coated porous carbon by low-temperature liquid phase polymerization. Take 0.4 g of the melamine-based porous carbon obtained in step 1) and uniformly disperse it in 200 mL of distilled water to form a suspension. Add 0.8 g cetyltrimethylammonium chloride, 4 ...

Embodiment 2

[0049] A preparation method of melamine-based coated porous carbon (the mass ratio of melamine-based porous carbon to pyrrole is 1:5), the steps not specified are the same as in Example 1, except that: step 2) adds The amount of pyrrole was 2 mL.

[0050] Figure 7 The lithium-sulfur battery prepared for Comparative Example 2 has a current density of 167.5 mA / cm 2 Cyclic performance image at time. The first discharge specific capacity of the lithium-sulfur battery of this comparative example is 1190 mAh / g, and after 200 cycles, the specific capacity decays to 360 mAh / g, and the cycle performance is greater than that of Example 1 when the capacity of the first cycle is close to that of Example 1. Due to the lack of sufficient outer coating to bind polysulfides, the dissolution and diffusion of polysulfides will produce a "shuttle effect" in the electrolyte, resulting in a decrease in cycle performance.

Embodiment 3

[0052] A preparation method of melamine-based coated porous carbon (the mass ratio of melamine-based porous carbon to pyrrole is 1:20), the steps not particularly specified are the same as in Example 1, the difference is that in step 2) add The amount of pyrrole was 8 mL.

[0053] Figure 8 The lithium-sulfur battery prepared for Comparative Example 3 had a current density of 167.5 mA / cm 2 Cyclic performance image at time. The first discharge specific capacity of the lithium-sulfur battery of this comparative example is 687 mAh / g, after 200 cycles, the specific capacity decays to 489 mAh / g, and the cycle performance is slightly improved, and its first cycle capacity is compared with that of Example 1 There is a large drop, due to the complete coating, the reaction area between the active material sulfur and the electrolyte is reduced, and the sulfur loading is also reduced to less than 50%.

[0054] The experimental results show that coating the porous carbon surface is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com