Numerical control laser cutting machine control system based on single-chip microcomputer

A control system, digital control laser technology, applied in the general control system, control/regulation system, digital control, etc., can solve the problems of low efficiency, low precision, high equipment cost, etc., to improve efficiency and quality, avoid interference, The effect of improving reliability and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

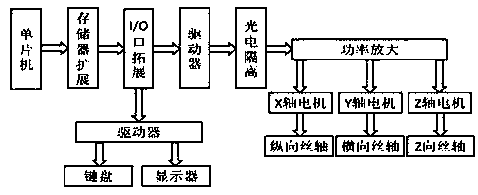

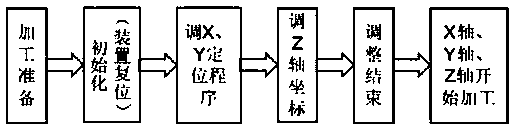

[0049] Such as Figure 1-Figure 3 As shown, a single-chip-based numerical control laser cutting machine control system provided in this embodiment includes a control circuit, a memory expansion board, an I / O port expansion board, two sets of drivers, a photoelectric isolator, a power amplifier, an X-axis motor, Y-axis motor, Z-axis motor, keyboard, monitor, longitudinal wire shaft, horizontal wire shaft, and Z-axis wire.

[0050] The control circuit is used for storing control programs to receive and send control information.

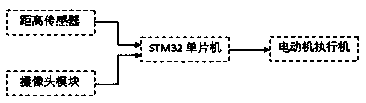

[0051] Such as Figure 4-Figure 13 As shown, the control circuit includes STM32STM32 F103ZET6 microcontroller, clock circuit, reset circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com