Reusable fiber bragg grating displacement sensor with display function and measuring method

A displacement sensor, fiber grating technology, applied in the field of measurement, can solve the problems of unreusable on-site installation, complex and inconvenient overall structure, insufficient resistance to electrical measurement interference, etc., to achieve easy multi-point multi-parameter online monitoring, unique application value , Not affected by electromagnetic field interference and temperature and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

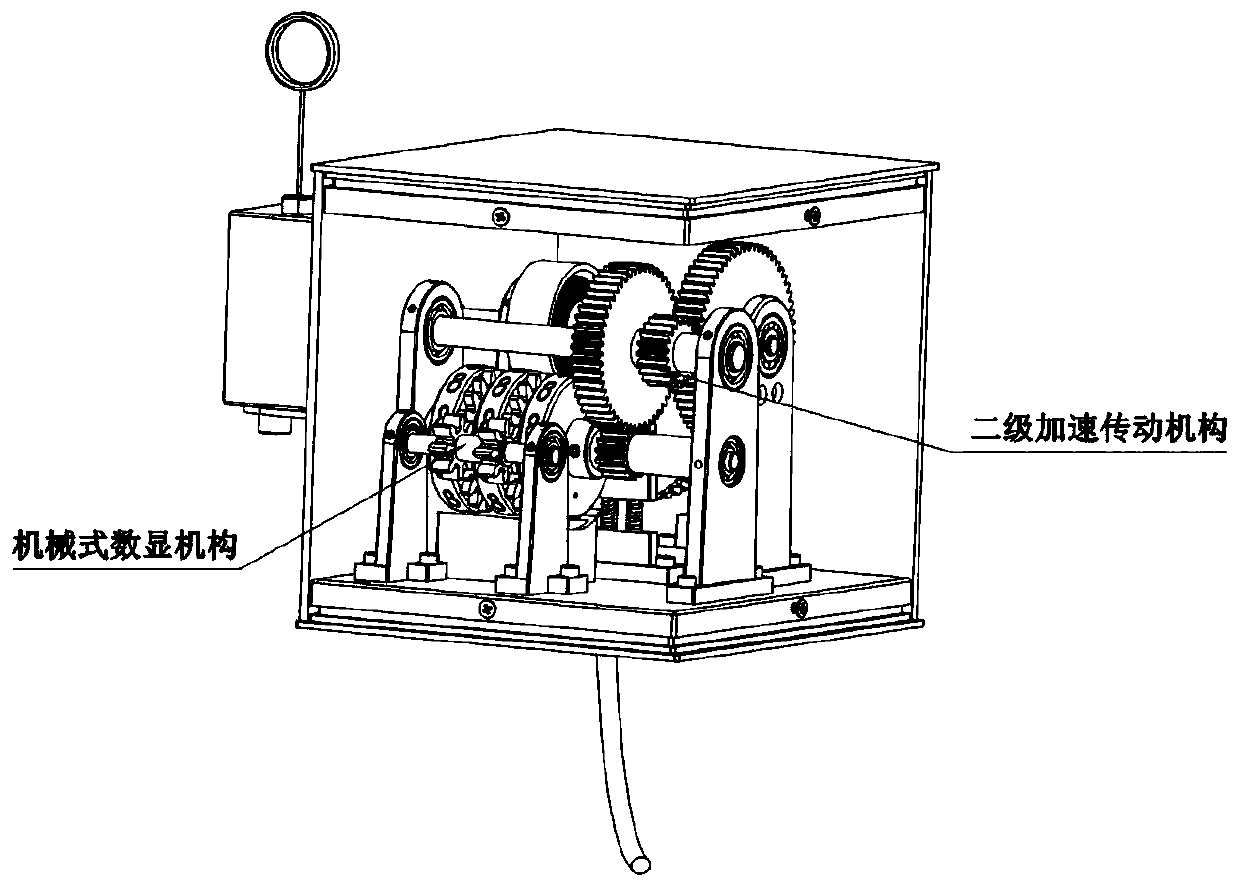

[0078] This embodiment discloses as figure 1 and figure 2As shown, a reusable fiber grating displacement sensor with self-contained display includes a sensor housing, a worm drive mechanism, a worm gear drive mechanism, a rack and pinion drive mechanism, a strain beam fixing mechanism, a winding wheel module, and a two-stage acceleration drive mechanism , Composed of mechanical digital display mechanism.

[0079] See attached image 3 As shown, in the specific implementation example, the sensor housing includes: sensor cylinder wall, sensor base, sensor upper cover, sensor housing sealing ring, optical cable fixing joint and armored optical cable;

[0080] The upper cover of the sensor, the base of the sensor, the sealing ring of the sensor housing and the wall of the sensor cylinder together form the airtight housing of the optical fiber grating displacement sensor. The outer side of the lower cover is provided with an optical cable fixing joint for fixing the optical cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com