Air-side air and water mixed fine atomization enhanced heat exchange system for air cooler

A technology that enhances heat transfer and air side. It is applied in the fields of liquid two-phase atomization, heat transfer and gas. consumption, the effect of the best cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

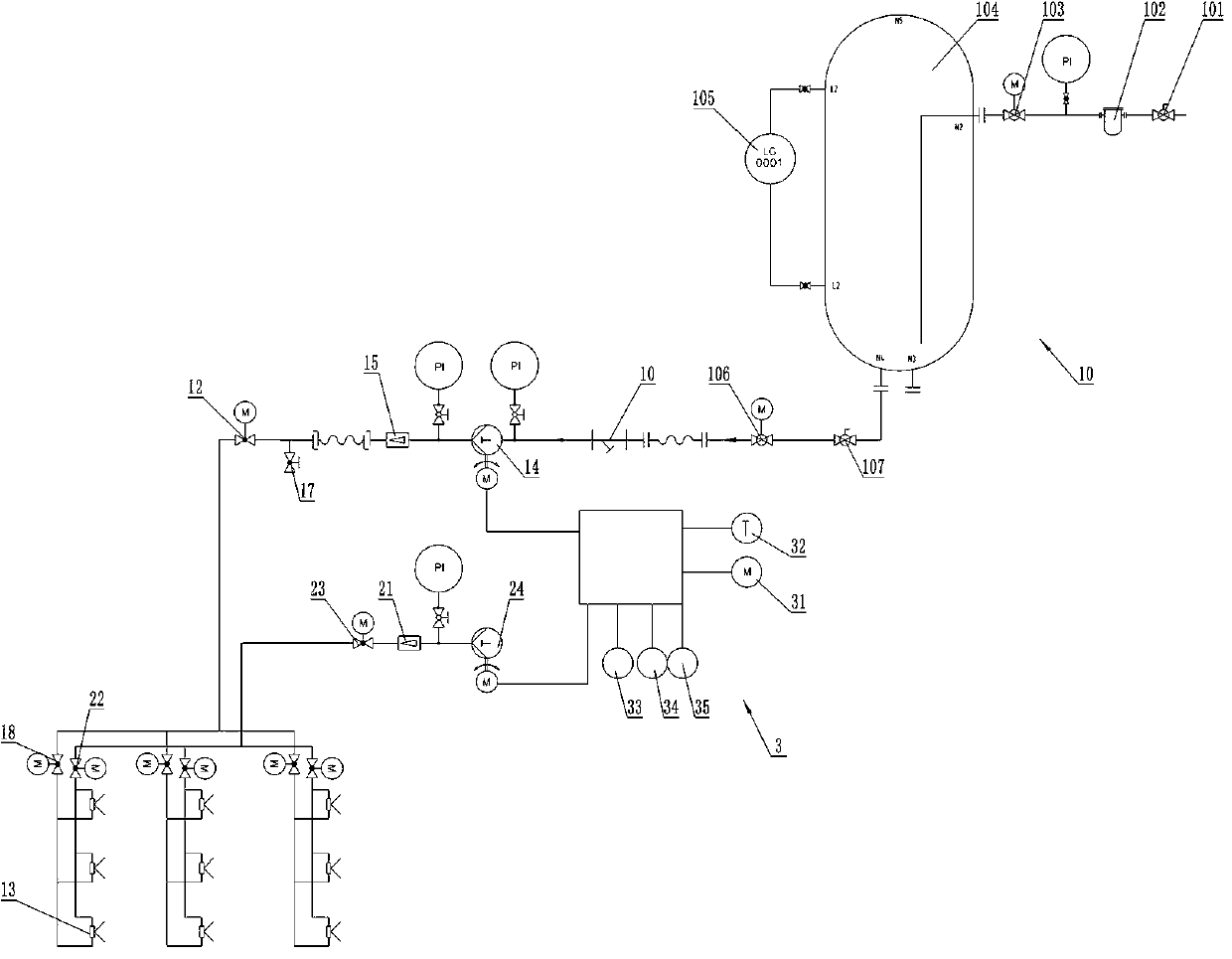

[0030] The following combination Figure 1~5 , the specific content of the present invention will be described in detail through specific embodiments. The air cooler uses air-side gas and water mixed fine atomization to enhance heat exchange system, which includes a water circuit assembly 1 , an air circuit assembly 2 , and a monitoring and control system 3 .

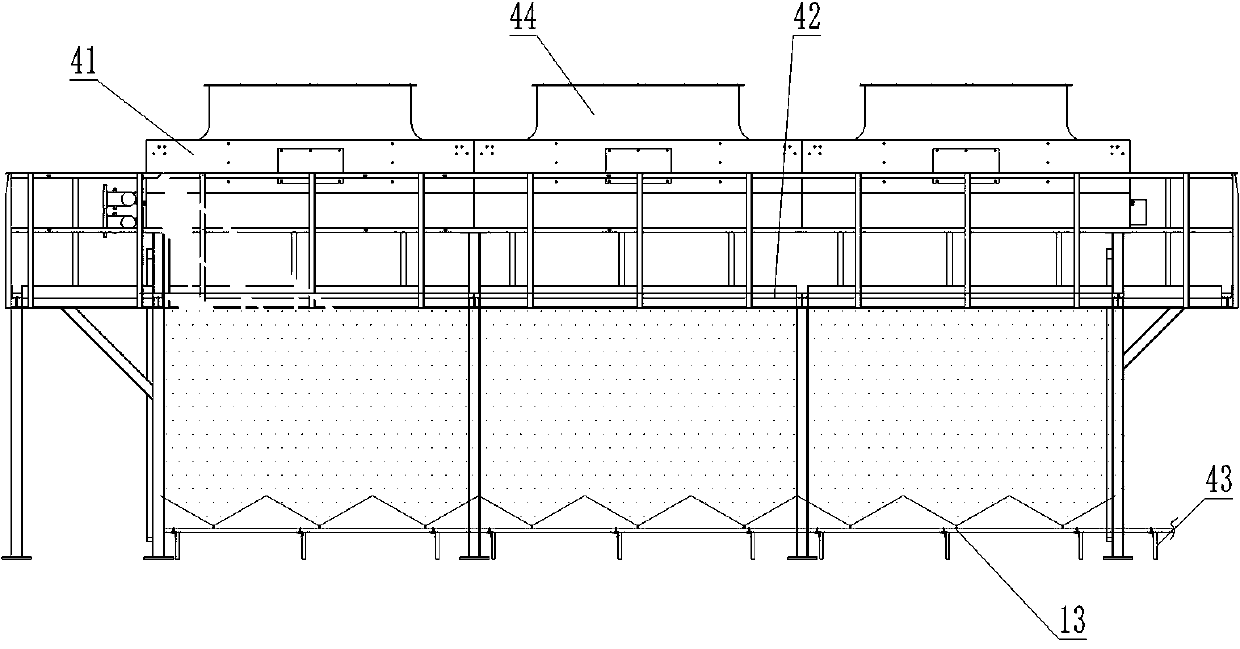

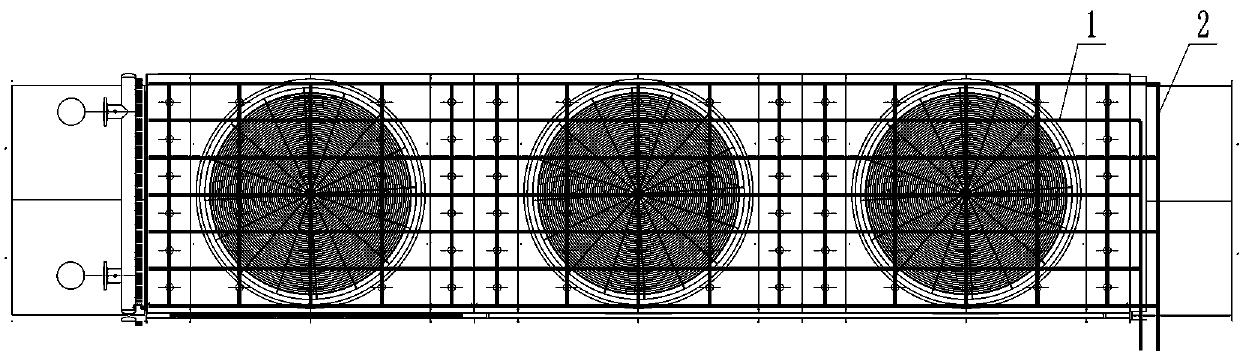

[0031] On the premise of not changing the steel structure of the original fin support 42, the pipeline support 43 is fixed on the fin support 42 by bolts or welding, so that the nozzle is located at the position of the air-cooling fan barrel 44, and the water mist is covered with the best The area covers the air cooling fins 41 .

[0032] The waterway assembly 1 includes a water supply assembly 10 and a secondary filter 11 arranged at the front end of the water pump 14, a first waterway electric valve 12 arranged at the rear end of the water pump 14, an emptying valve 17, and several second Waterway electric valve 18;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com