Construction method of reinforced concrete wall

A technology of reinforced concrete and construction method, applied in the direction of walls, building components, buildings, etc., can solve the problems of difficulty in meeting the strength requirements of reinforced concrete, weak compressive strength and crack resistance, and achieve improved compactness, compressive strength and The effect of strong crack resistance, enhanced compressive strength and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

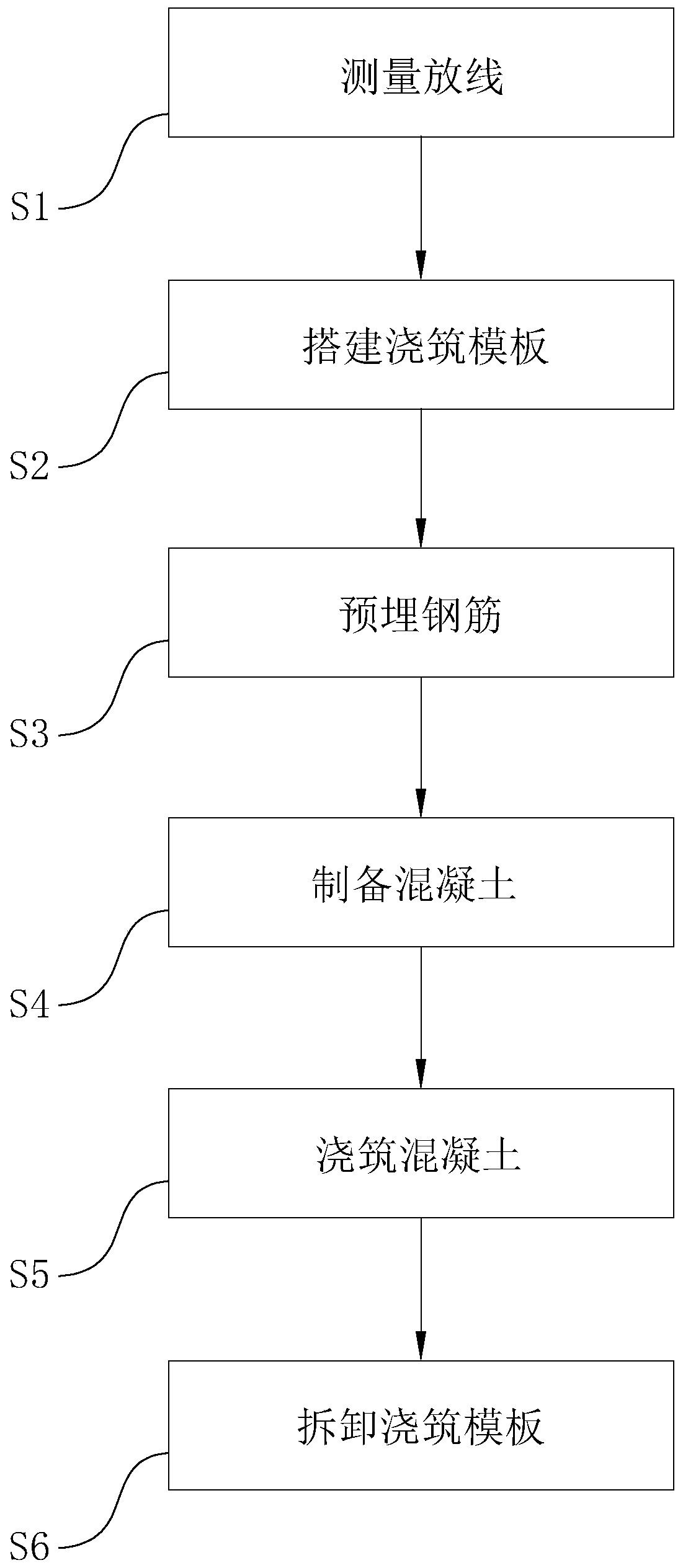

[0064] A construction method for a reinforced concrete wall, comprising the steps of:

[0065] S1. Measurement and setting-out, details are as follows:

[0066] Measure the size of the site and the length and width of the wall according to the design drawings, and mark the installation position of the wall.

[0067] S2. Build the pouring formwork, as follows:

[0068] Build the pouring formwork for the wall according to the position marked by S1.

[0069] S3. Pre-embedded steel bars, details are as follows:

[0070] According to the design drawings, the steel bars are pre-embedded, bound and fixed in the pouring formwork.

[0071] S4, prepare concrete, specifically as follows:

[0072] In a 150L stirring tank, stir at a speed of 220r / min under normal temperature conditions, and add 20kg of Portland cement, 12kg of water, 77.5kg of sand, 10kg of fly ash, 7kg of mineral powder, and 1kg of silane coupling agent while stirring. , 3 kg of fatty alcohol polyoxyethylene ether, 1...

Embodiment 2

[0080] The difference with Example 1 is: add Portland cement 22.5kg, water 11kg, sand 80kg, fly ash 12.5kg, mineral powder 5kg, silane coupling agent 0.5kg, fatty alcohol polyoxyethylene ether 2kg, 0.5 kg of o-nitrododecyl ether, 0.02 kg of 6-phenyl-3-pyridazinone.

Embodiment 3

[0082] The difference from Example 1 is that in step S4, 25kg of Portland cement, 10kg of water, 75kg of sand, 15kg of fly ash, 6kg of mineral powder, 0.75kg of silane coupling agent, 1kg of fatty alcohol polyoxyethylene ether, and 0.75 kg of dodecyl ether, 0.01 kg of 6-phenyl-3-pyridazinone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com