A kind of spiral liquid nitrogen freezer and method

A freezer and spiral technology, applied in the field of spiral liquid nitrogen freezers, can solve the problems of increasing the loss of liquid nitrogen cooling capacity, and achieve the effects of improving stability, high cooling transfer efficiency, and improving freezing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following description of the embodiments refers to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced.

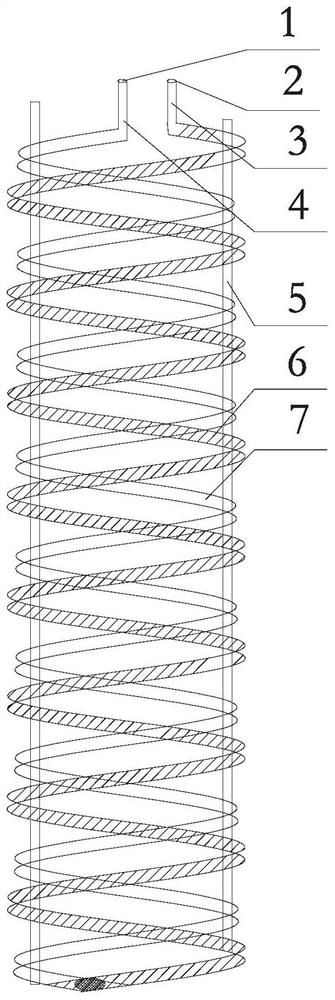

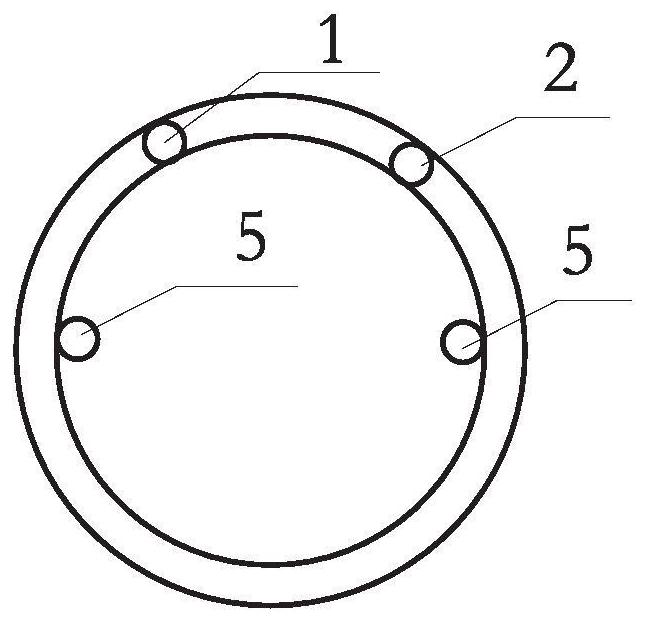

[0016] Such as figure 1 with 2 As shown, the spiral liquid nitrogen freezer of the present invention includes a liquid supply pipe 3 and a gas return pipe 4, and one end of the liquid supply pipe 3 and the gas return pipe 4 is connected to each other, and the other end is respectively provided with a liquid supply pipe mouth 2 and a gas return pipe mouth 1. The liquid supply pipe 3 and the air return pipe 4 are spiral structures, the liquid supply pipe 3 is provided with a liquid supply pipe helical ring 6 with the same diameter as the freezing hole, and the air return pipe 4 is provided with a return pipe with the same diameter as the freezing hole. The helical circle 7 of the air pipe, the helical circle 6 of the liquid supply pipe on the liquid supply pipe 3 and the air return pipe 4 and the helical circle 7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com