Medium-low speed maglev variable-gauge track structure capable of being quickly adjusted

A variable track, low-speed technology, applied to tracks, roads, buildings, etc., can solve the problems of high construction costs and achieve the effects of reducing construction costs, consistent movement, and improving bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

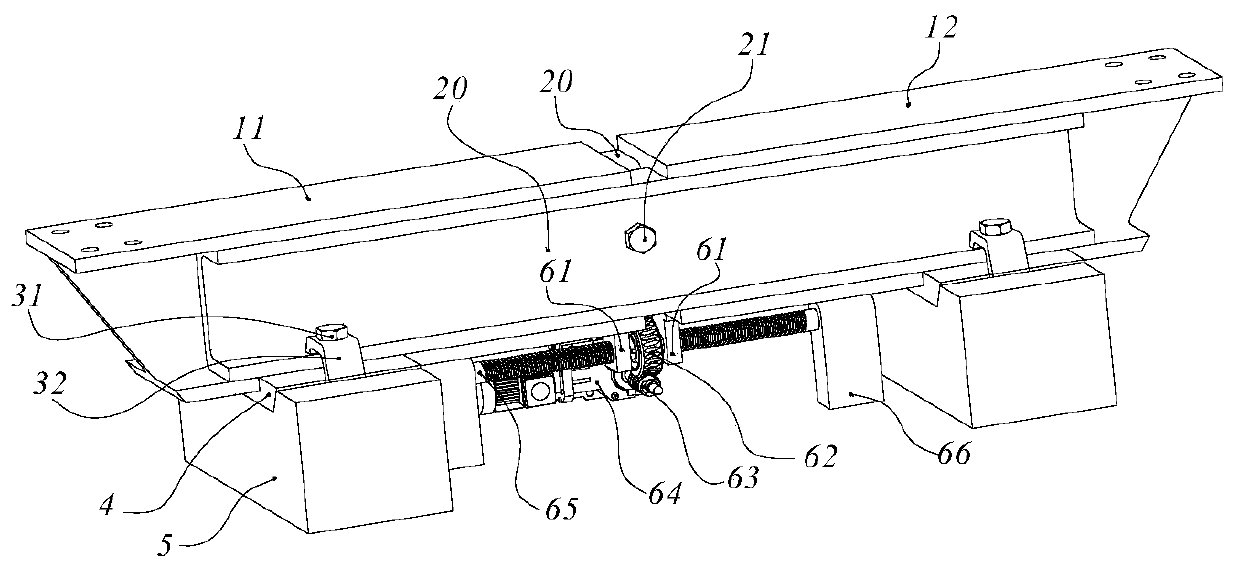

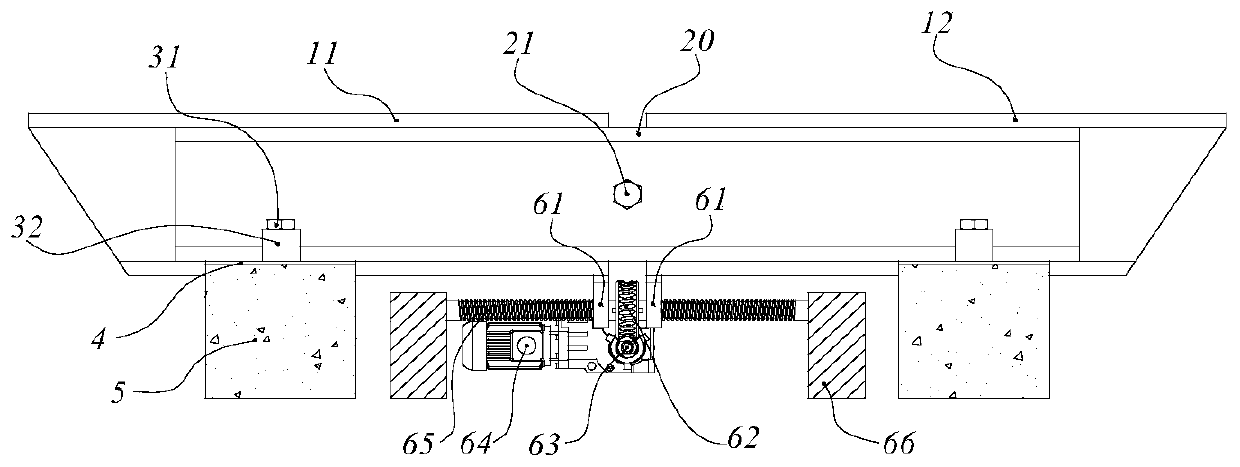

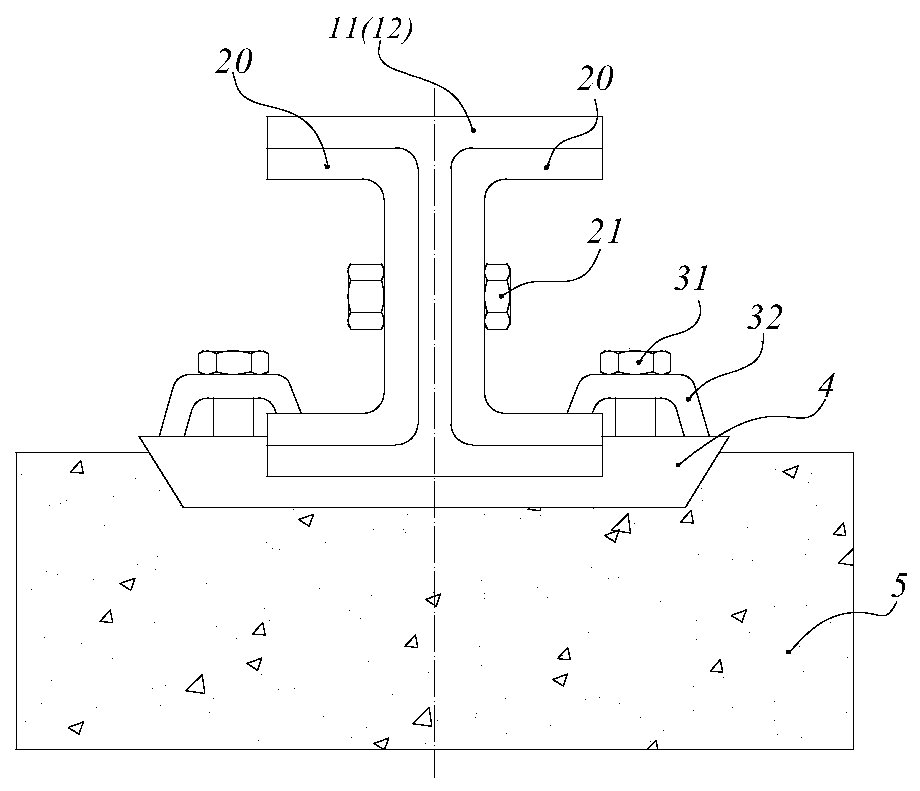

[0028] refer to figure 1 , figure 2 , image 3 , Figure 8 and Figure 9 , the present invention can quickly adjust the medium and low speed maglev variable gauge track structure, including the buckle row composed of the left sleeper 11, the right sleeper 12, the F-shaped guide rail 7, the rail support platform 5 and the fastener system 3, and the horizontal interval The left sleeper 11 and the right sleeper 12 are arranged in pairs along the line extension direction, and the F-shaped guide rail 7 is fixedly installed on the top surface, and each left sleeper 11 and right sleeper 12 pass through the fastener system 3 and the rail bearing platform below it 5 to form a connection. The cross-sections of the left side sleeper 11 and the right side sleeper 12 are I-shaped, and U-shaped plates 20 corresponding to their contours are respectively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com