Offshore wind power generation set horizontally-assembling and integrally-overturning-and-erecting installation system and method

A technology for wind turbines and installation systems, which is applied to wind turbine components, wind engines, wind power generation, etc., and can solve problems such as slow assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

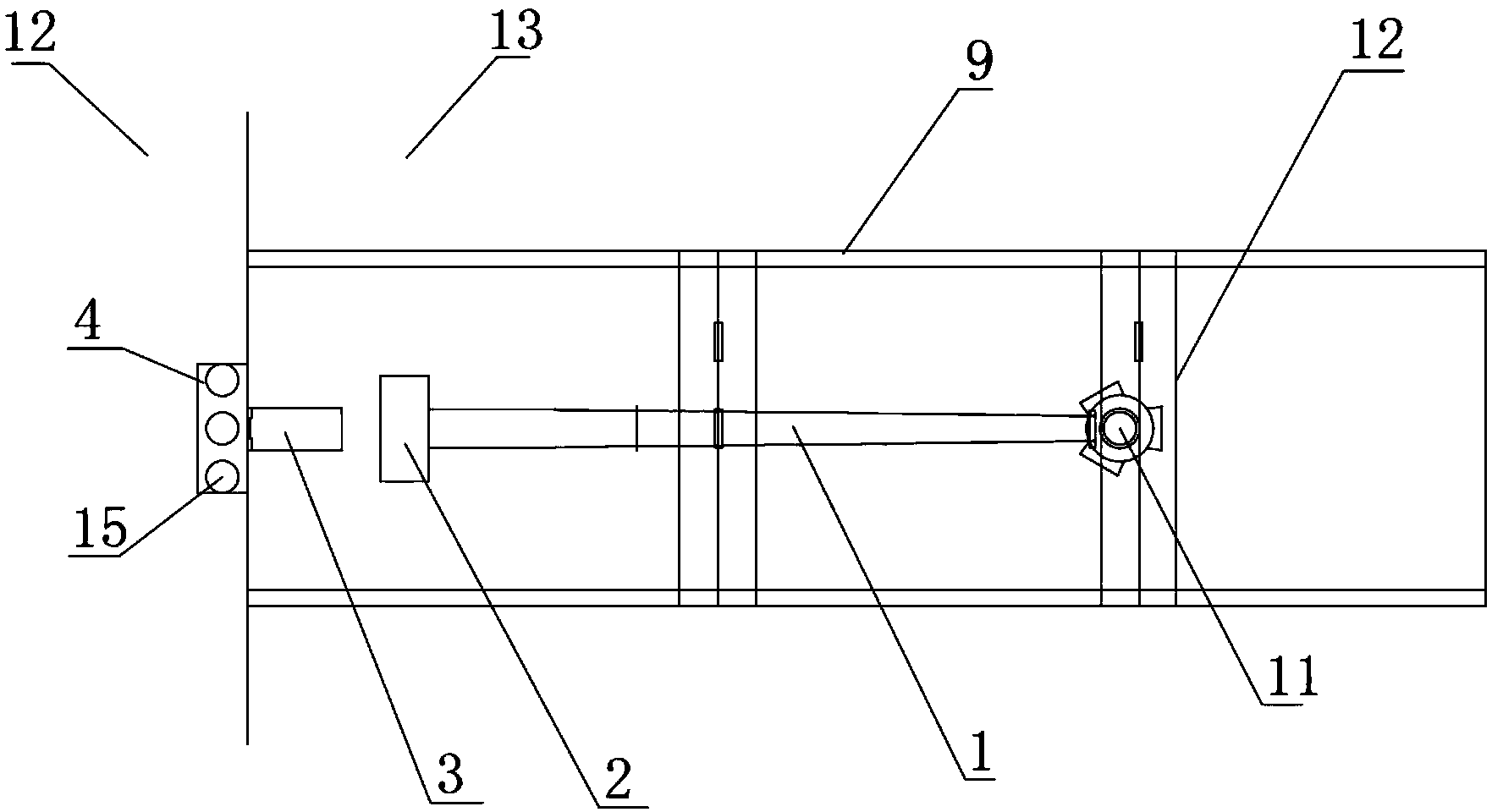

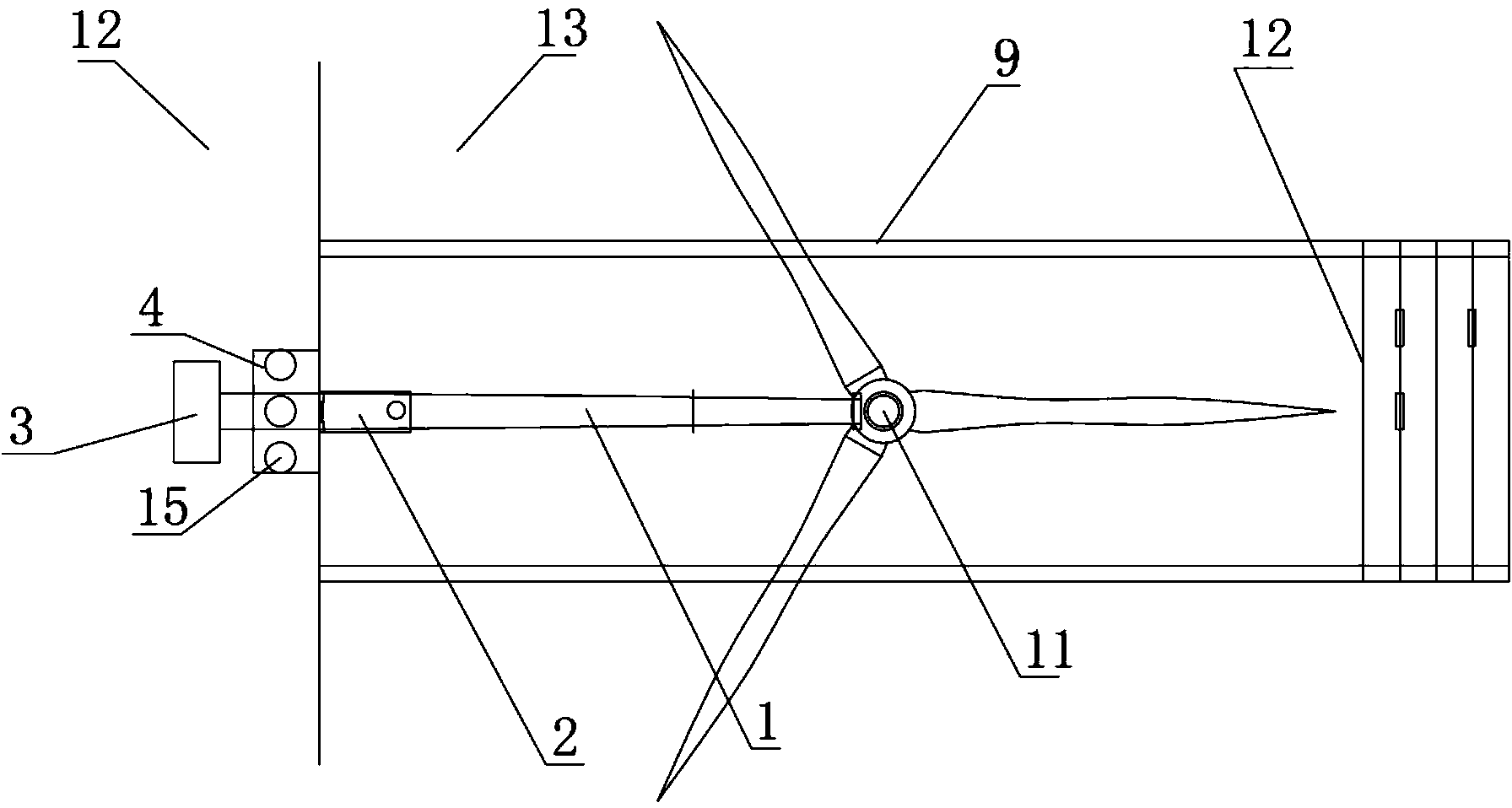

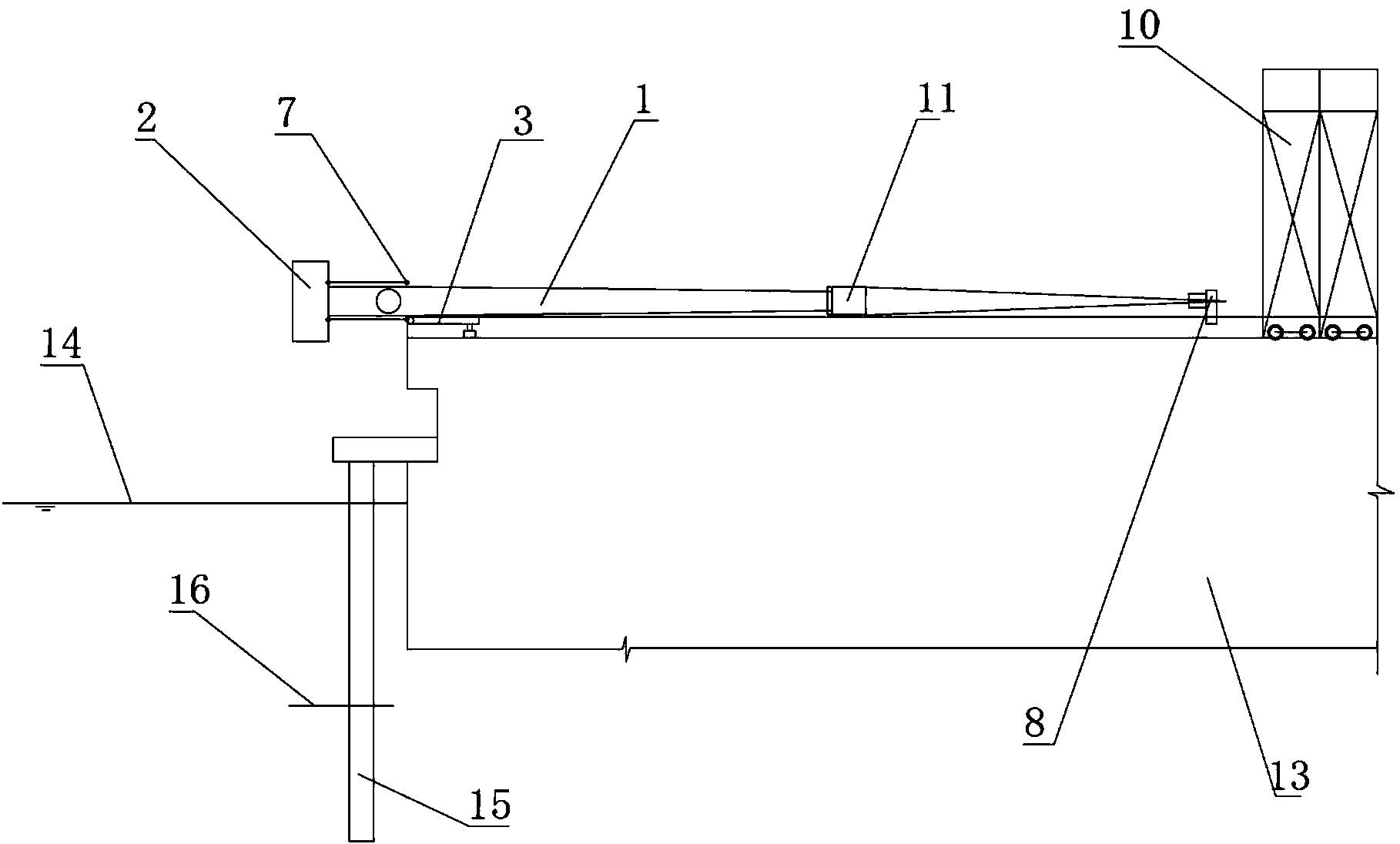

[0020] Such as Figure 1 to Figure 5 As shown, the horizontal assembly of the offshore wind power generating set of the present invention is integrally flipped and erected, and includes a detachable ballast system 2 installed at the bottom of the wind tower 1, which can preferably be loaded with water or sand, and is set on the side of the wharf. Device 3, the support platform 4 arranged under the turning device 3, the turning device 3 includes a turning support plate 5 hinged on the edge of the dock to match the shape of the tower 1, one end is hinged on the turning support plate 5 and the other end is hinged on the dock The hydraulic cylinder 6, the ballast system 1 is connected to the tower 1 through the ballast automatic detachment device 7, and the measurement, control and correction system 8 is set on the wharf.

[0021] A method for horizontally assembling an offshore wind power generating set and turning it over and erecting as a whole, comprising the following steps, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com