Layer-by-layer self-assembly composite conductive fiber bundle and preparation method thereof

A layer-by-layer self-assembly and composite conductive technology, which is applied in fiber processing, physical processing, textiles and papermaking, etc., can solve the problems of narrow adjustable range of conductive properties, brittle mechanical properties of conductive fibers, and inability to transition, so as to improve the surface of fibers Effects of combining weak defects, improving fiber surface activity, and optimizing interface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a layer-by-layer self-assembled composite conductive fiber bundle, comprising the following steps:

[0035] S1, performing surface decontamination treatment on the fiber monofilaments, and then performing drying treatment to obtain fiber bundles; performing oxygen plasma treatment on the fiber bundles for a predetermined time to obtain physically modified fiber bundles;

[0036] S2, putting the physically modified fiber bundle prepared in step S1 into an electropositive dispersion liquid of a predetermined concentration, and performing an electropositive substance adsorption treatment for a predetermined time to obtain a fiber bundle deposited with an electropositive substance; then Take out the fiber bundle deposited by the electropositive substance, drain it slightly and wash it, then put it into the electronegative dispersion liquid of predetermined concentration, carry out the electronegative substance adsorption treatmen...

Embodiment 1

[0048] A method for preparing a layer-by-layer self-assembled composite conductive fiber bundle, comprising the steps of:

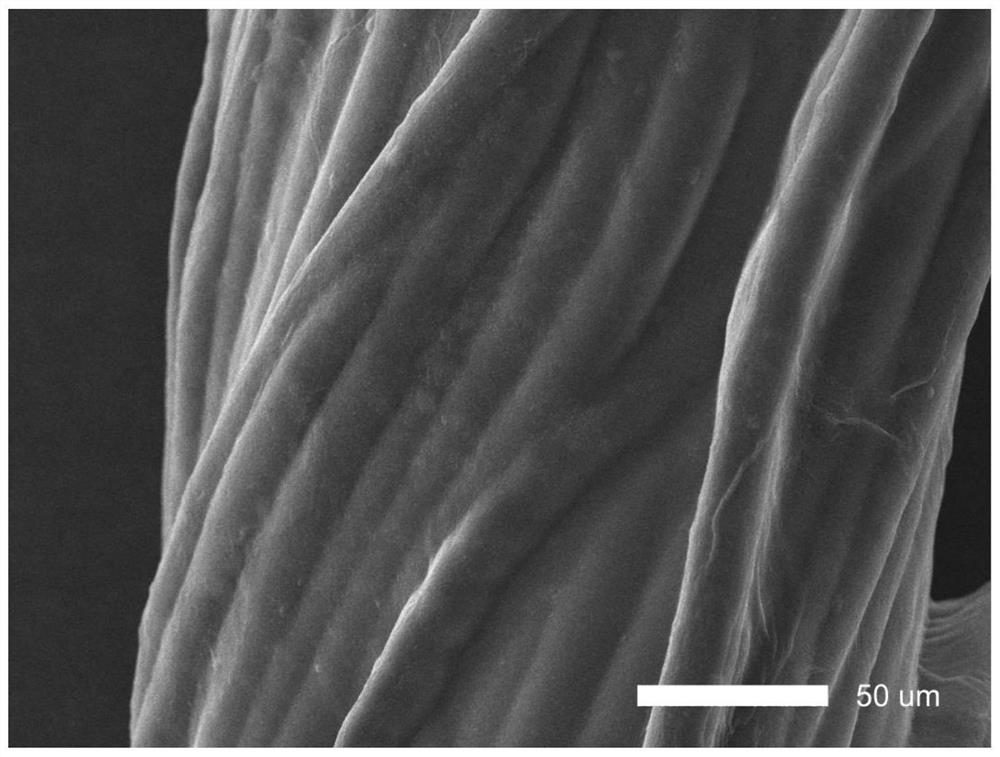

[0049] S1, put the cotton fiber monofilament into deionized water, absolute ethanol, and acetone in sequence for ultrasonic cleaning for 15 minutes to ensure that the previous step is cleaned, and then proceed to the next step of cleaning after drying at room temperature. After the last step of acetone ultrasonic cleaning is completed, Dry at room temperature, arrange and obtain cotton fiber bundles; carry out oxygen plasma treatment to the cotton fiber bundles, the processing parameters are as follows: the current is 1.00A, the duty cycle is 80%, the automatic discharge time is 600s, and the automatic discharge pressure is 2000Pa ;

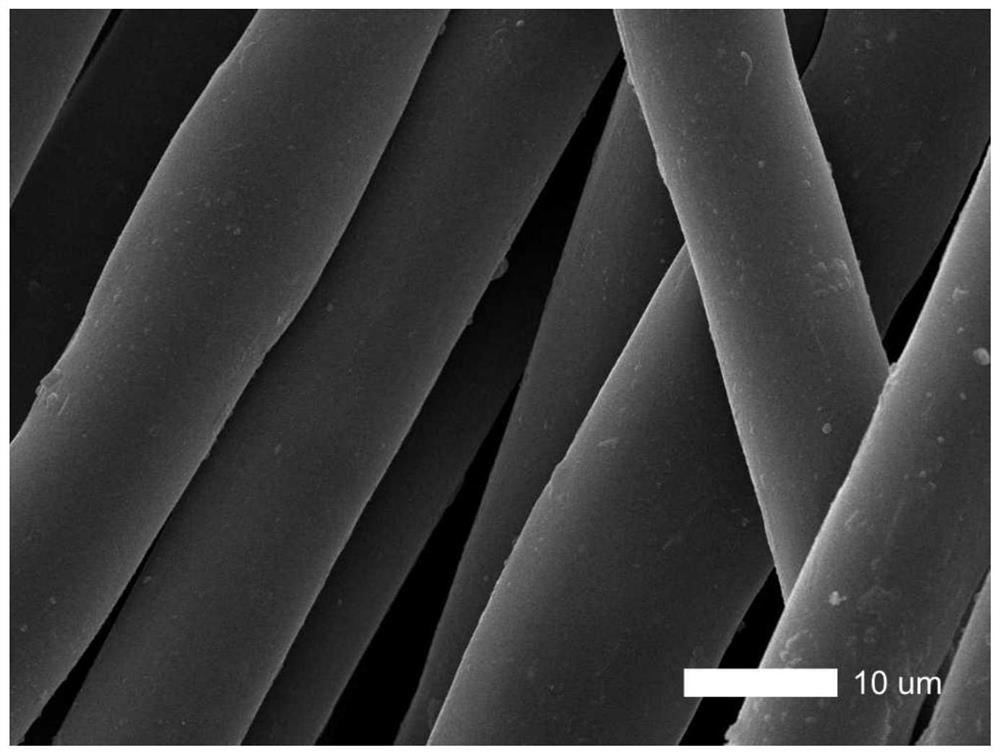

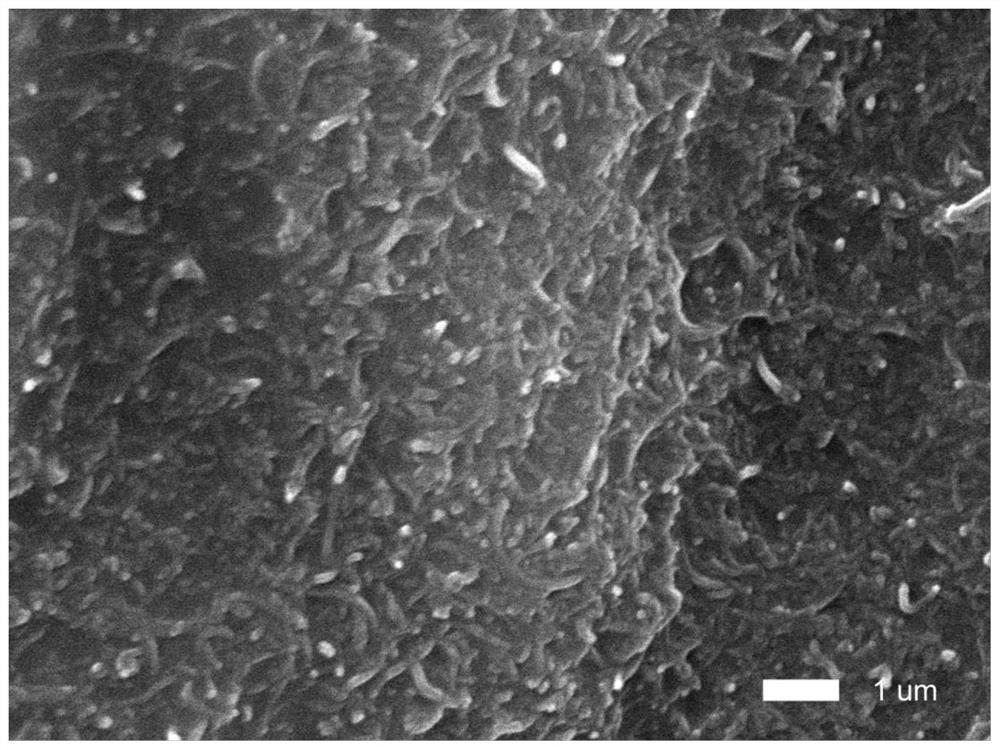

[0050] S2, put the fiber bundle prepared in step S1 into polydiallyldimethylammonium chloride modified carbon nanotube (PDCNT) dispersion (wherein, PDDA concentration is 0.25wt%, carbon nanotube concentration is 0.5wt%), ca...

Embodiment 2

[0061] The difference with Example 1 is: the number of layers of alternate adsorption treatment in step S2 is 2 layers, and the PDCNT / PEDOT:PSS conductive composite cotton fiber with 2 layers of self-assembly is prepared, and other steps are the same as in Example 1, and are not described here Let me repeat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com