Water-based PU impregnation processing technology of automobile interior microfiber leather

A technology for automobile interior decoration and processing technology, applied in the direction of motor vehicles, road vehicles, vehicle parts, etc., can solve the problems of increasing cancer and leukemia, easily causing poisoning of operators, and poisoning consumers, and achieves great prospects and production technology. Green environmental protection, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

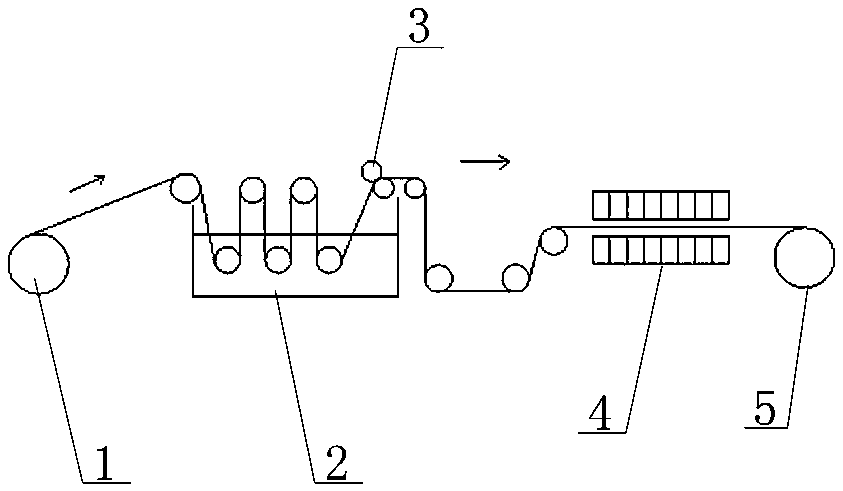

[0020] refer to figure 1 , the present invention a kind of water-based PU impregnation processing technology of microfiber leather for automotive interior, comprising the steps:

[0021] Step 1) Place base cloth roll 1 on the unwinding stand;

[0022] Step 2) Preparation of water-based PU emulsion: mix the polyurethane emulsion with an appropriate amount of water and stir evenly;

[0023] Step 3) Add the stirred polyurethane emulsion into the impregnation tank 2 through the feeding barrel, and raise the temperature to 50°C-80°C;

[0024] Step 4) The base cloth is impregnated through the impregnation tank 2, and then pressed through the roll 3;

[0025] Step 5) Drying in the oven 4 and finally winding by the winding roller 5 .

[0026] Further, the base cloth roll 1 in the step 1) is superfine fiber white non-woven fabric with a grammage of 120-350g / m², a roll length of 500m-1000m, and a width of 140-200cm.

[0027] Further, the water-based PU in the step 2) is a milky whit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com