Preparation method of lampblack air filtering material

An air filter material and oil fume technology, which is applied in the field of fibers to achieve the effects of improving filtering efficiency, increasing surface area and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

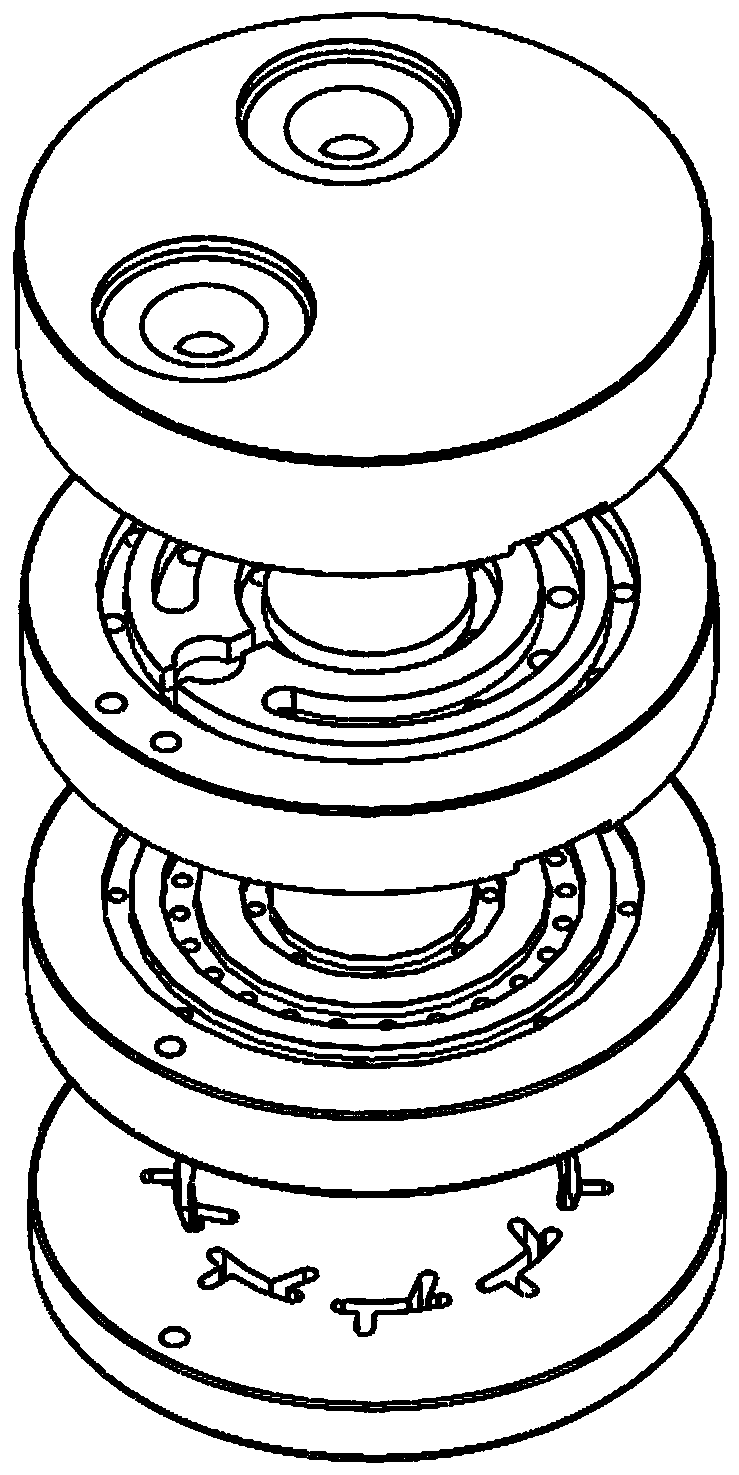

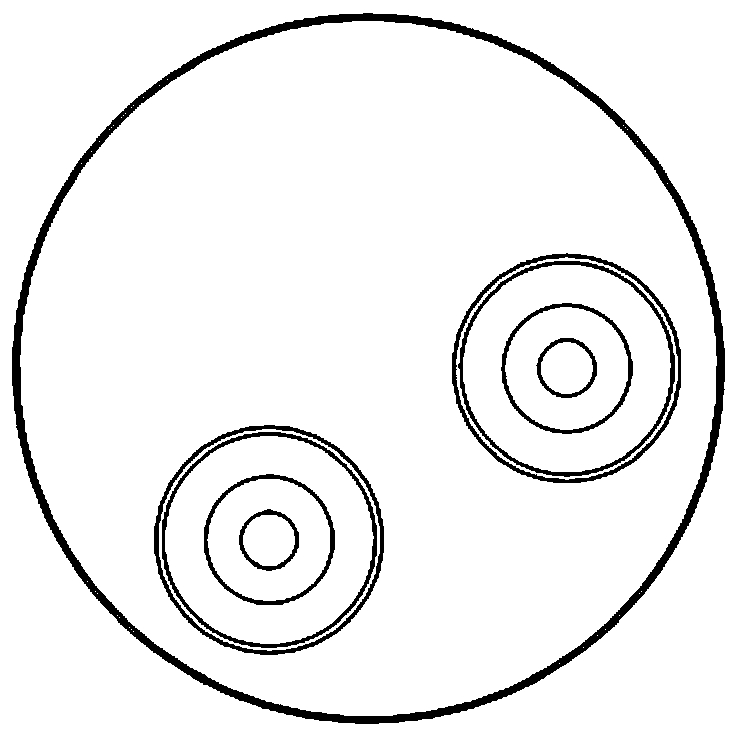

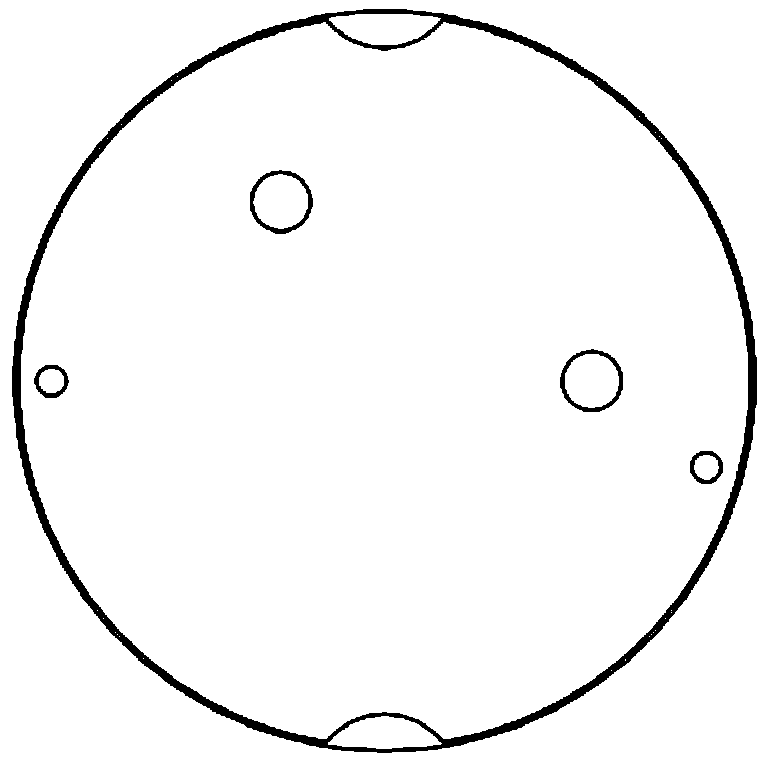

Image

Examples

Embodiment 1

[0047] A preparation method of oil fume air filter material, the steps are as follows:

[0048] (1) Preparation of self-twisting fibers:

[0049] According to the short filament spinning process, a composite spinning component located in the component spinning box is used to mix PET melt (intrinsic viscosity 0.55dL / g) and PTT melt (intrinsic viscosity 1.1dL) with a mass ratio of 45:55 / g) after dispensing, from the same spinneret Short filaments are obtained by extruding through shaped spinneret holes, which are obtained from twisted fibers;

[0050] The flow of short filament spinning process is: extrusion→cooling→oiling→winding→storage→converging→water bath drafting→steam drafting→tension heat setting→curling→cutting→relaxing heat setting; The parameters are: the relaxation heat setting temperature is 100°C, the temperature of the PET melt spinning box is 280°C, the temperature of the PTT melt spinning box is 273°C, the temperature of the component spinning box is 276°C, ...

Embodiment 2

[0067] A preparation method of oil fume air filter material, the steps are as follows:

[0068] (1) Preparation of self-twisting fibers:

[0069] According to the short filament spinning process, the composite spinning assembly located in the component spinning box is used to mix PET melt (intrinsic viscosity is 0.58dL / g) and PTT melt (intrinsic viscosity is 1.2dL) with a mass ratio of 47:53 / g) After distribution, short filaments are extruded from the spinneret holes of the same spinneret, i.e. obtained from twisted fibers;

[0070] The flow of short filament spinning process is: extrusion→cooling→oiling→winding→storage→converging→water bath drafting→steam drafting→tension heat setting→curling→cutting→relaxing heat setting; The parameters are: the relaxation heat setting temperature is 109°C, the temperature of the PET melt spinning box is 282°C, the temperature of the PTT melt spinning box is 273°C, the temperature of the component spinning box is 276°C, the cooling tempera...

Embodiment 3

[0087] A preparation method of oil fume air filter material, the steps are as follows:

[0088] (1) Preparation of self-twisting fibers:

[0089] According to the short filament spinning process, the composite spinning assembly located in the component spinning box is used to mix PET melt (intrinsic viscosity 0.6dL / g) and PTT melt (intrinsic viscosity 1.1dL) with a mass ratio of 50:50 / g) After distribution, short filaments are extruded from the spinneret holes of the same spinneret, i.e. obtained from twisted fibers;

[0090] The flow of short filament spinning process is: extrusion→cooling→oiling→winding→storage→converging→water bath drafting→steam drafting→tension heat setting→curling→cutting→relaxing heat setting; The parameters are: the relaxation heat setting temperature is 109°C, the temperature of the PET melt spinning box is 283°C, the temperature of the PTT melt spinning box is 275°C, the temperature of the component spinning box is 278°C, the cooling temperature 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com