Three-dimensional weaving tension control method

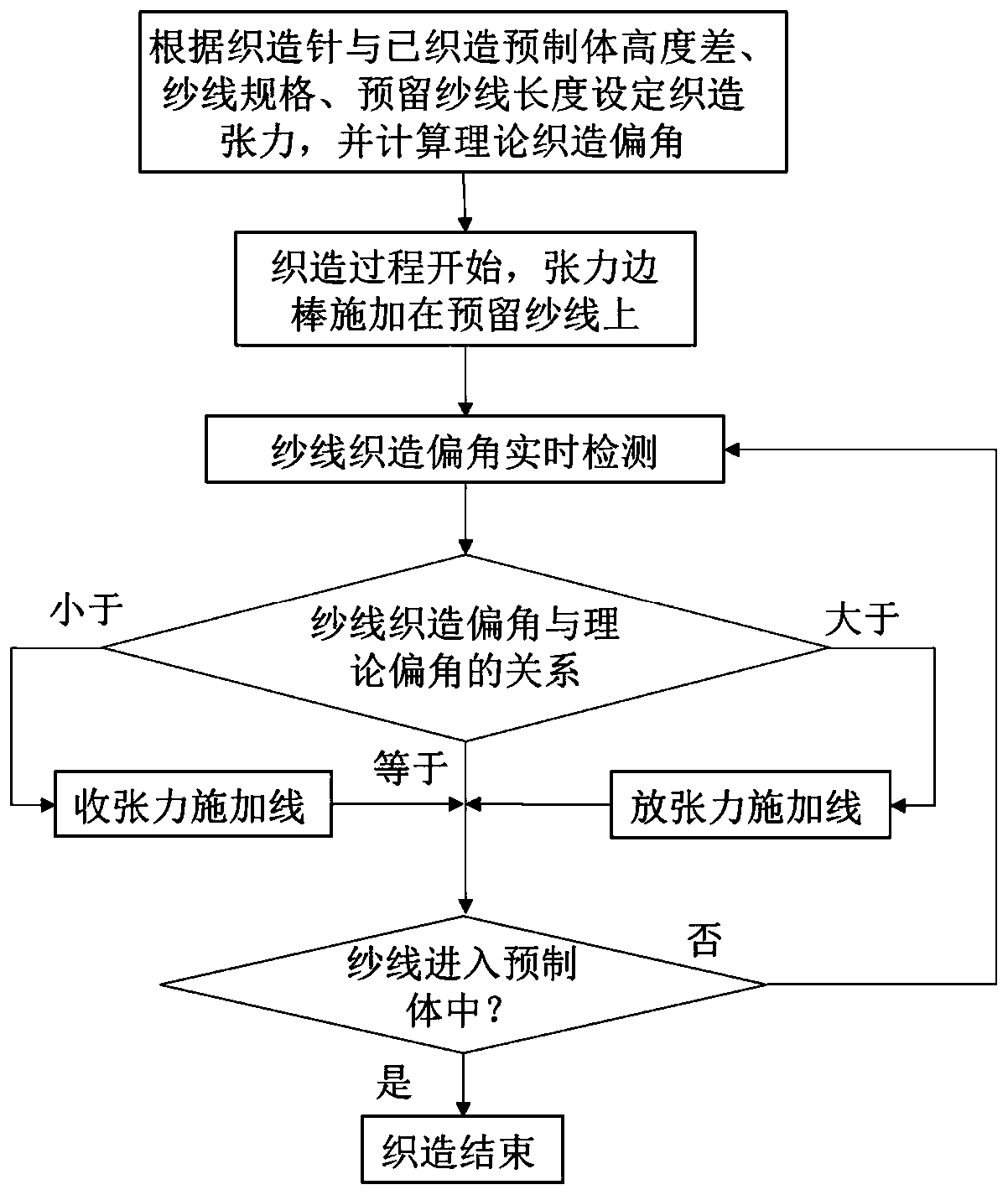

A technology of tension control and three-dimensional weaving, which is applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of difficult control of weaving tension, reduce yarn wear, reduce yarn knotting, and facilitate high-quality forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below in conjunction with the accompanying drawings.

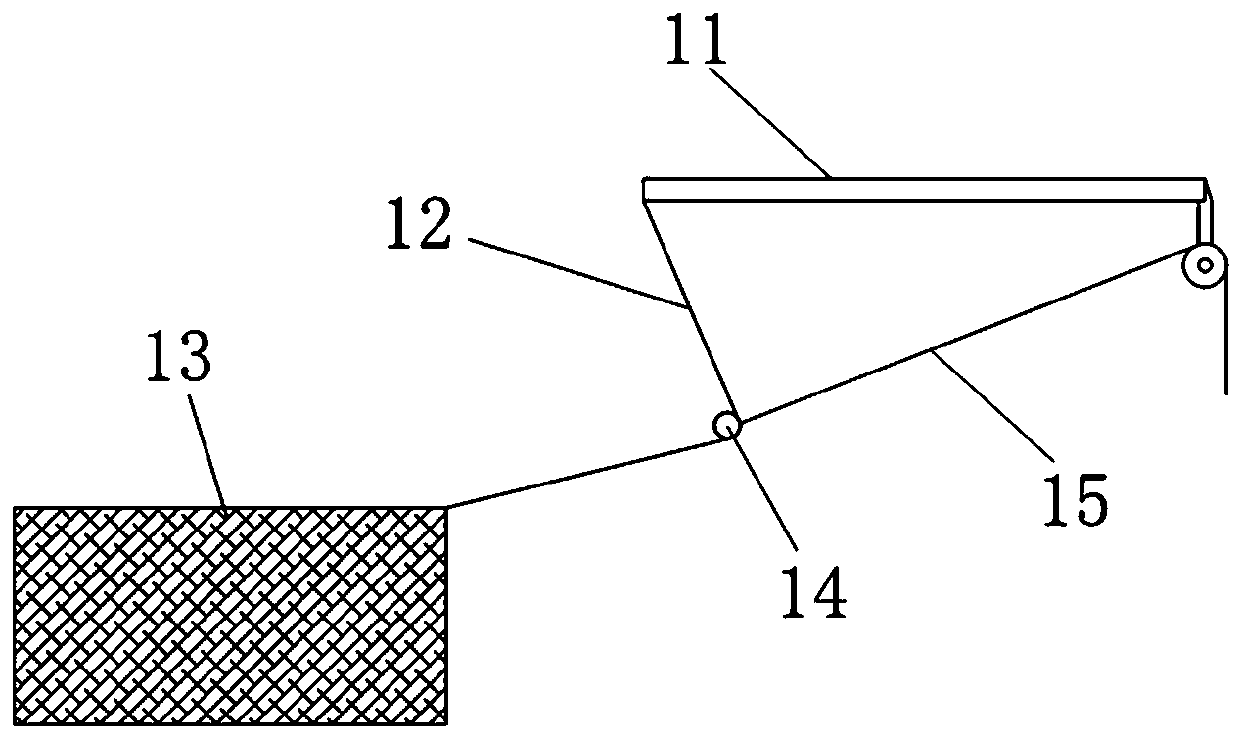

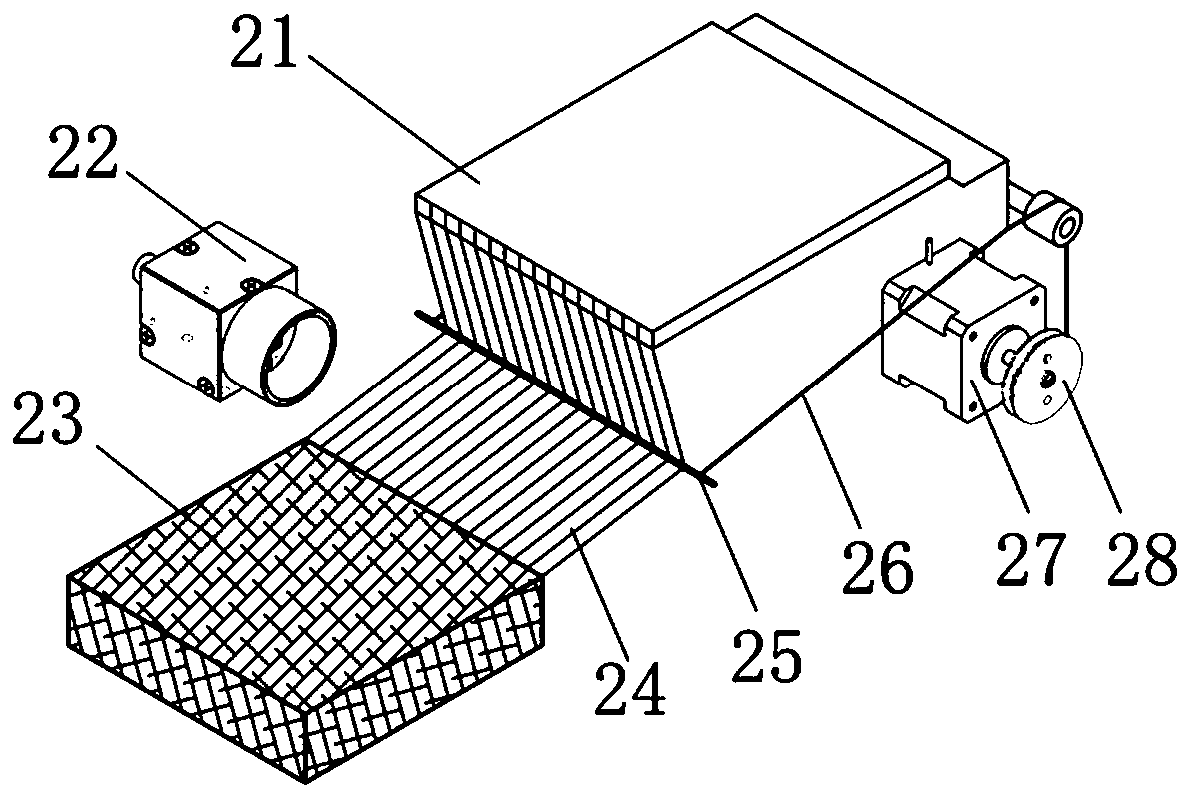

[0022] According to a typical embodiment of the present invention, such as figure 2 As shown, according to the height difference between the weaving needle 21 and the woven prefabricated body 23 of 75mm, the tension side rod 25 selects a stainless steel rod with a diameter of 3mm, the yarn 24 is T300-3K carbon fiber multifilament, and the reserved length is 310mm, and the yarn in the weaving process is set. The tension of the thread 24 is 25cN, and the theoretical weaving deflection angle between the yarn 24 and the ground gradually decreases from 6.9° to 2.6° during the weaving process of the weaving needle 21 .

[0023] During the weaving process, the weaving needle 21 moves horizontally toward the pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com